Pulse fiber laser based on side pumping technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

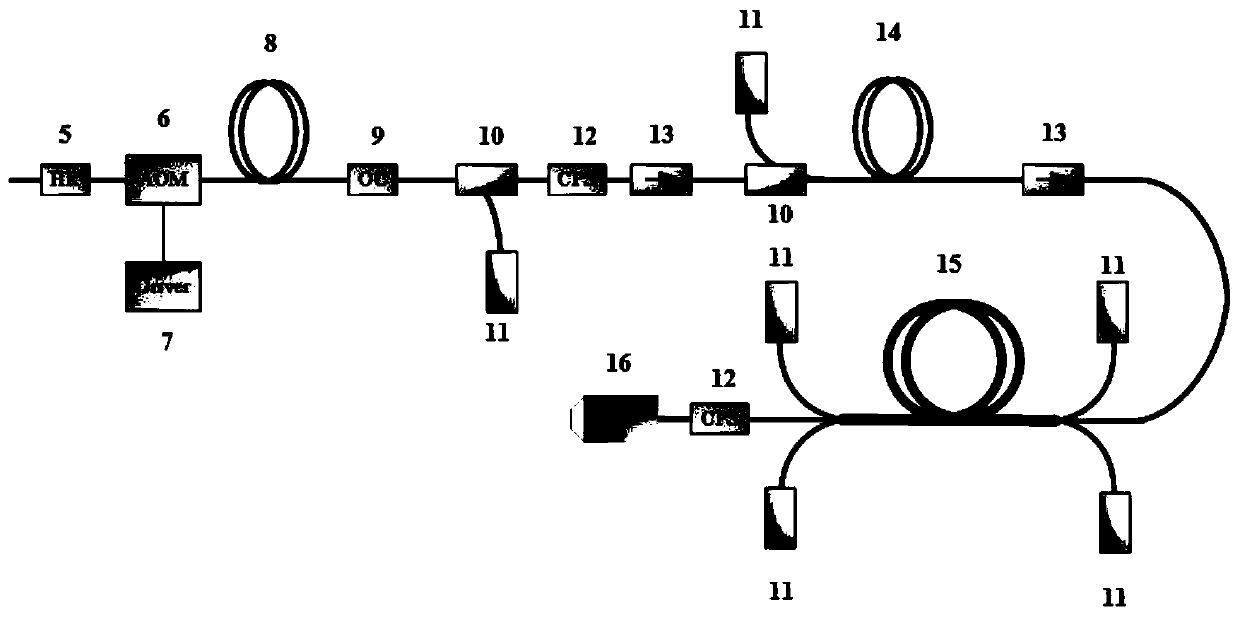

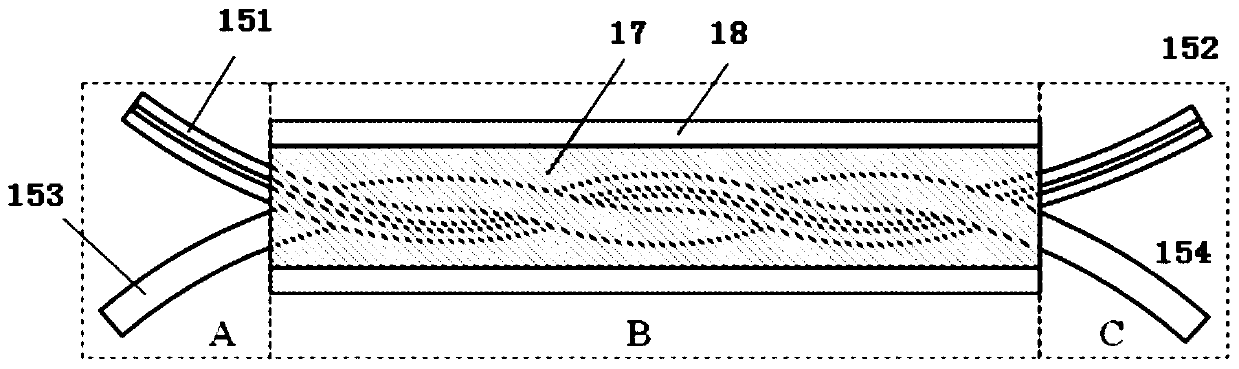

[0045] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

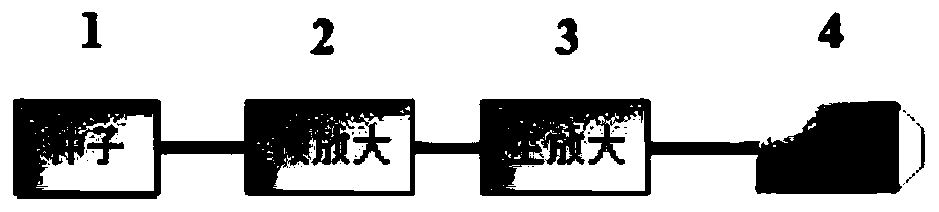

[0046] Such as figure 1 , 2 As shown, the present application provides a pulsed fiber laser based on side pumping technology, which can be used in various application scenarios, such as material surface cleaning, laser drilling, etc.

[0047] Specifically, pulsed fiber lasers based on side-pumped technology

[0048] Including: seed source generation unit, pre-amplification unit, main amplification unit;

[0049] A seed source generation unit is used to generate pulsed laser light according to the resonant cavity with reverse pumping function;

[0050] A pre-amplification unit for performing pulse-type laser gain amplification;

[0051] The main amplification unit is used to realize the secondary amplification of the pulsed laser based on the side-pumped fiber;

[0052] Wherein, the seed source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com