In-plant part inventory path adjustment and optimization intelligent system

A path adjustment and intelligent system technology, applied in data processing applications, forecasting, instruments, etc., can solve the problems of low efficiency of parts inventory, achieve the effects of improving efficiency, facilitating overall management, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

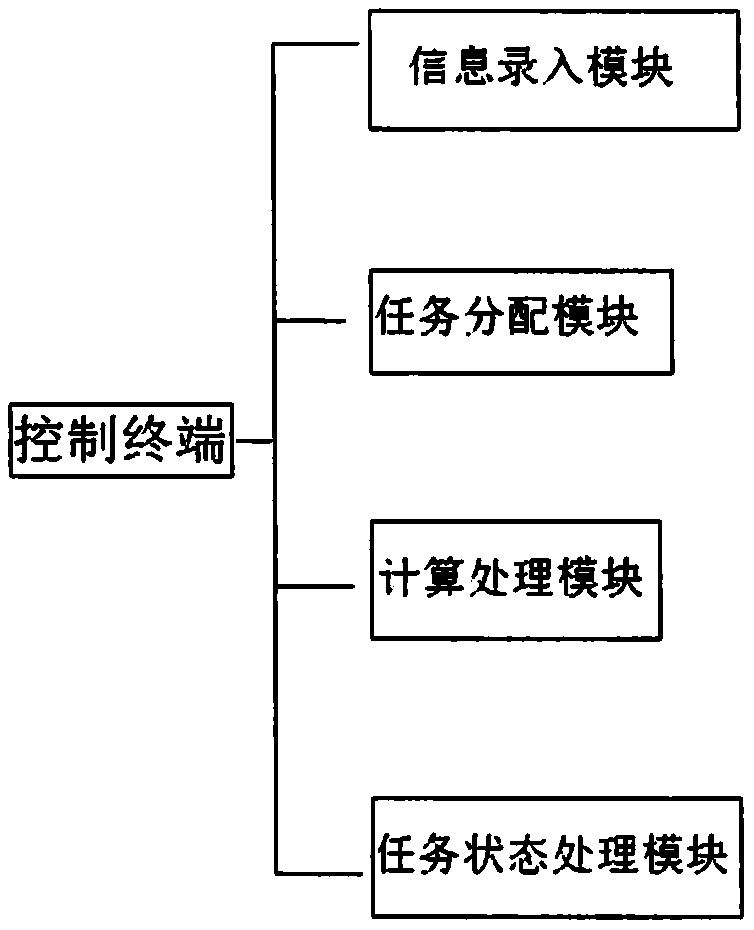

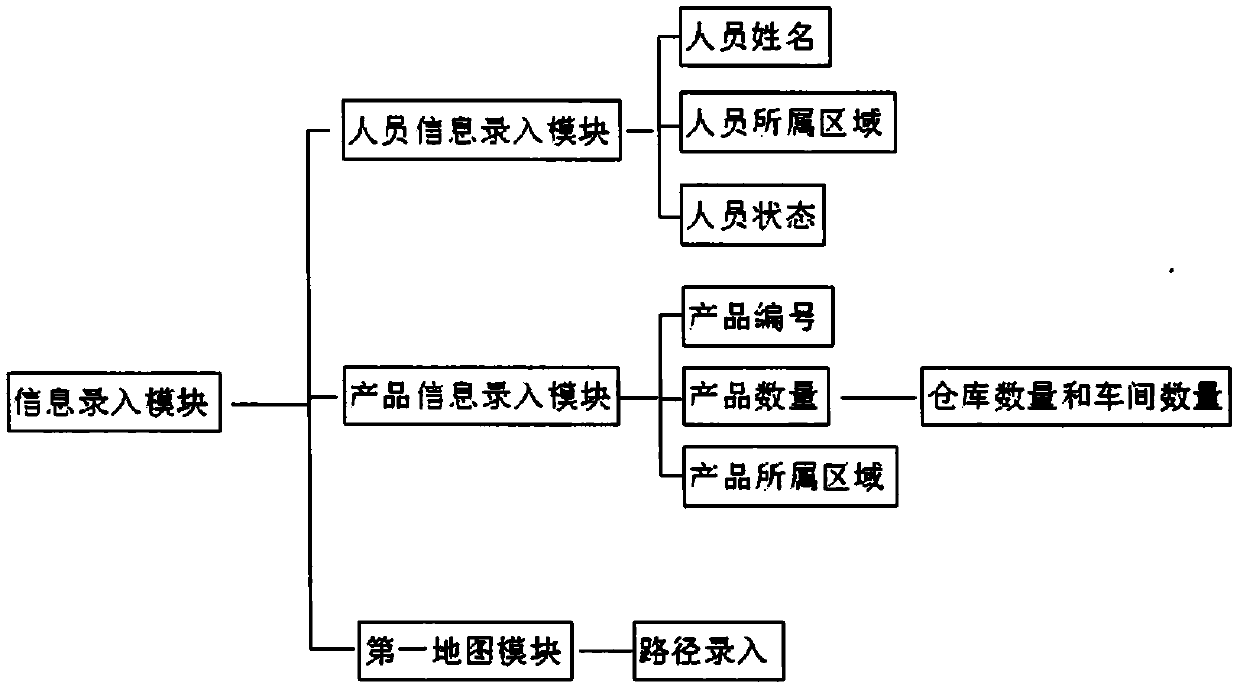

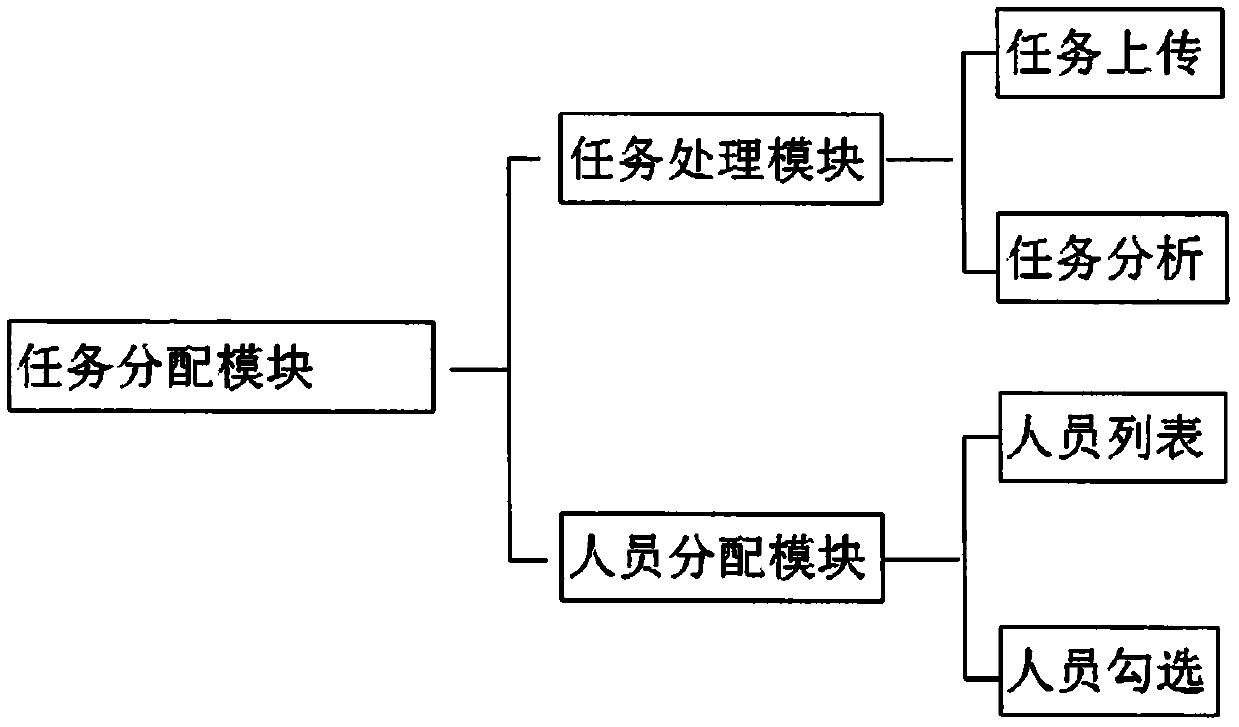

[0028] Example 1, please refer to figure 1 As shown, an intelligent system for adjusting and optimizing the inventory path of parts in the factory includes a control terminal and an execution terminal. The control terminal includes an information input module, a task assignment module, a calculation processing module, and a task status processing module. The information status of the personnel and the information status of the product are entered to facilitate the subsequent overall management. The task assignment module is set to organize and analyze the tasks that need to be completed and assign the matching personnel. Through the calculation and processing module, the personnel to be assigned and the parts and products to which they belong Match and sort the product parts that need to be counted and the counting order, and then optimize the path of each inventory, select the optimized path with the shortest distance, and reduce the time spent on the route during inventory. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com