Three-dimensional assembly process teaching method and system based on ergonomic simulation analysis

A technology of assembly process and simulation analysis, applied in the direction of design optimization/simulation, simulation device of space navigation conditions, simulator, etc., can solve the problems of no assembly process analysis, lack of assembly process optimization, and weak process guidance, etc., to achieve Eliminate reading burden, realize refined and scientific management, and improve the effect of on-site assembly mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

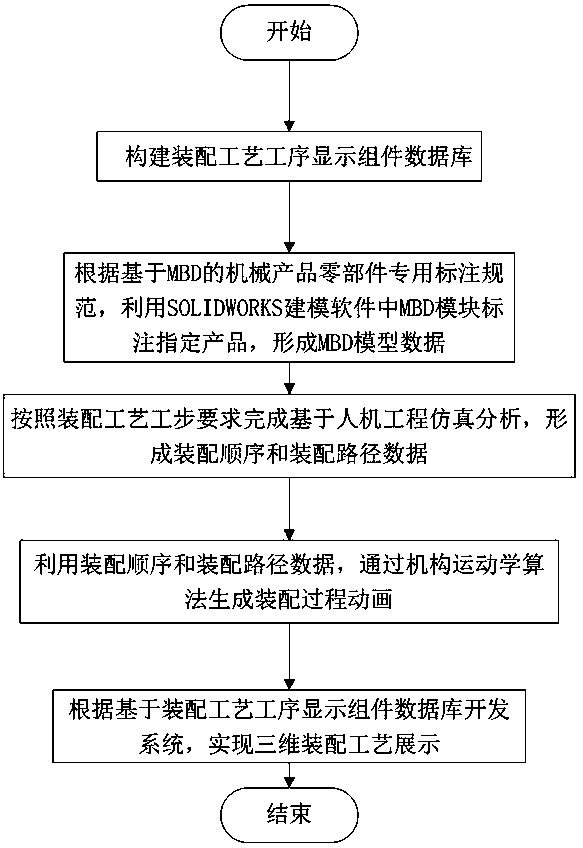

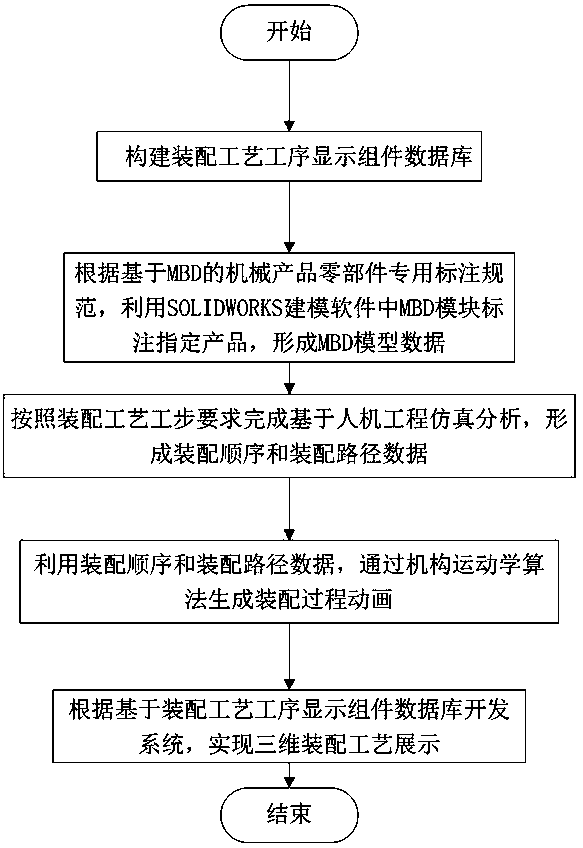

[0044] A teaching method for three-dimensional assembly process of wheeled tractors based on ergonomics simulation analysis provided by the embodiment of the present invention can be referred tofigure 1 , including the following steps:

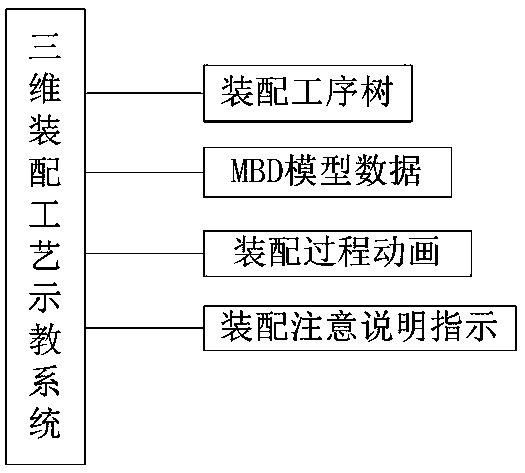

[0045] Step 1. Build the assembly process display component database, including data items such as assembly process tree, assembly attention instructions, MBD model data, assembly process animation, etc.

[0046] Step 2. According to the MBD-based special labeling specification for mechanical product parts, use the MBD module in the SOLIDWORKS modeling software to mark the specified product to form MBD model data.

[0047] Step 3. Based on the ergonomics simulation analysis, complete the assembly sequence and assembly path data based on the ergonomics simulation analysis according to the assembly proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com