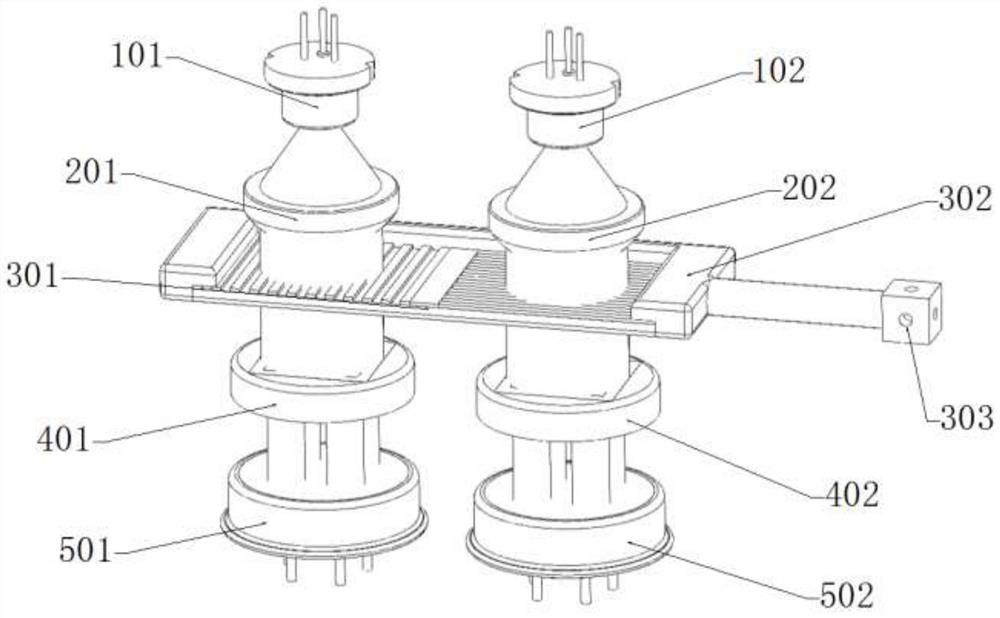

Two-dimensional micro-displacement sensor based on four-quadrant grating and detector

A four-quadrant detector, two-dimensional micro-displacement technology, applied in instruments, measuring devices, optical devices, etc., can solve problems such as inability to improve accuracy, low reliability, and difficulty in installation, and achieve improved resolution and accuracy. Increase the range and eliminate the effect of low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The embodiment parameters of the two-dimensional micro-displacement sensor based on four-quadrant grating and detector are as follows:

[0034] Laser wavelength: λ=635nm;

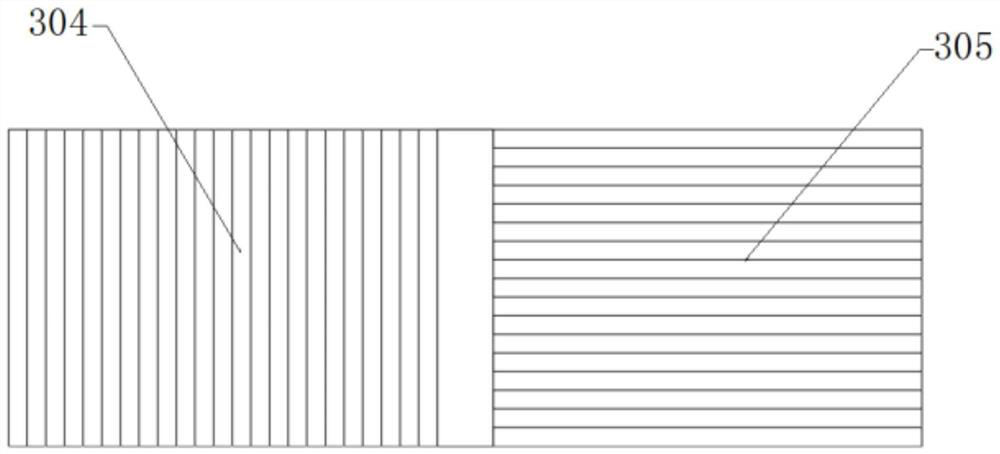

[0035] Movable grating period: d=800nm;

[0036] Four-quadrant grating period: d=800nm.

[0037] The specific analysis is as follows:

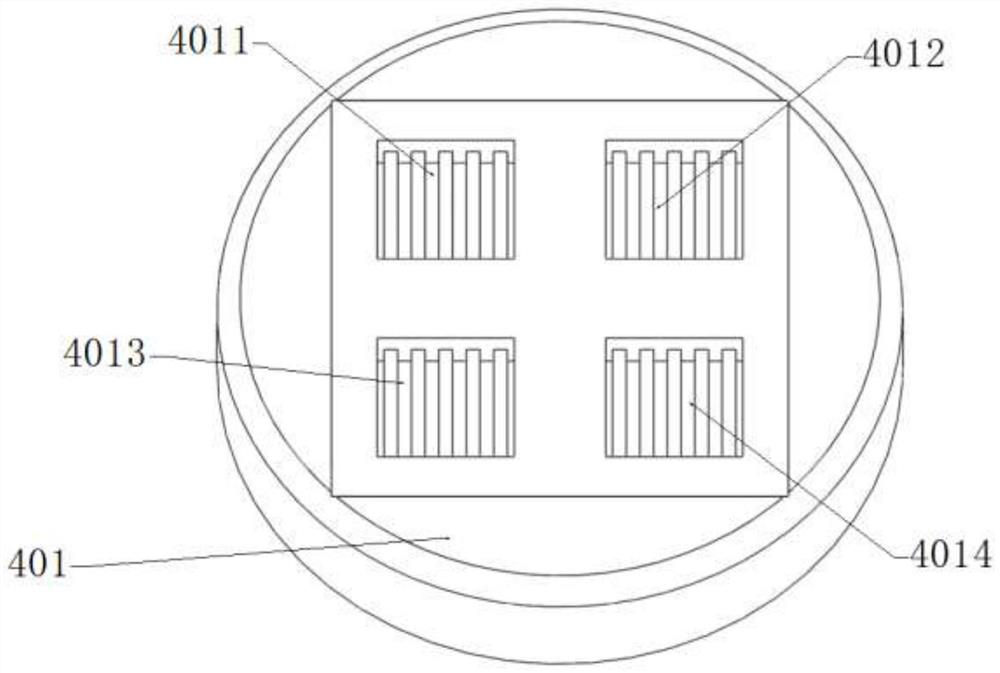

[0038] The intensity of light passing through the first quadrant is:

[0039]

[0040] The intensity of light passing through the second quadrant is:

[0041]

[0042] The intensity of light passing through the third quadrant is:

[0043]

[0044] The intensity of light passing through the fourth quadrant is:

[0045]

[0046] The light intensity difference through the first quadrant grating and the third quadrant grating is:

[0047]

[0048] The light intensity difference passing through the second quadrant grating and the fourth quadrant grating is:

[0049]

[0050] From the above derivation, it can be seen that the DC offset of the light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com