CFG pile and construction method thereof

A construction method and an integrated technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as subsidence, uneven mixing of internal materials, and poor use effects, so as to achieve stable positions, improve efficiency, and use effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

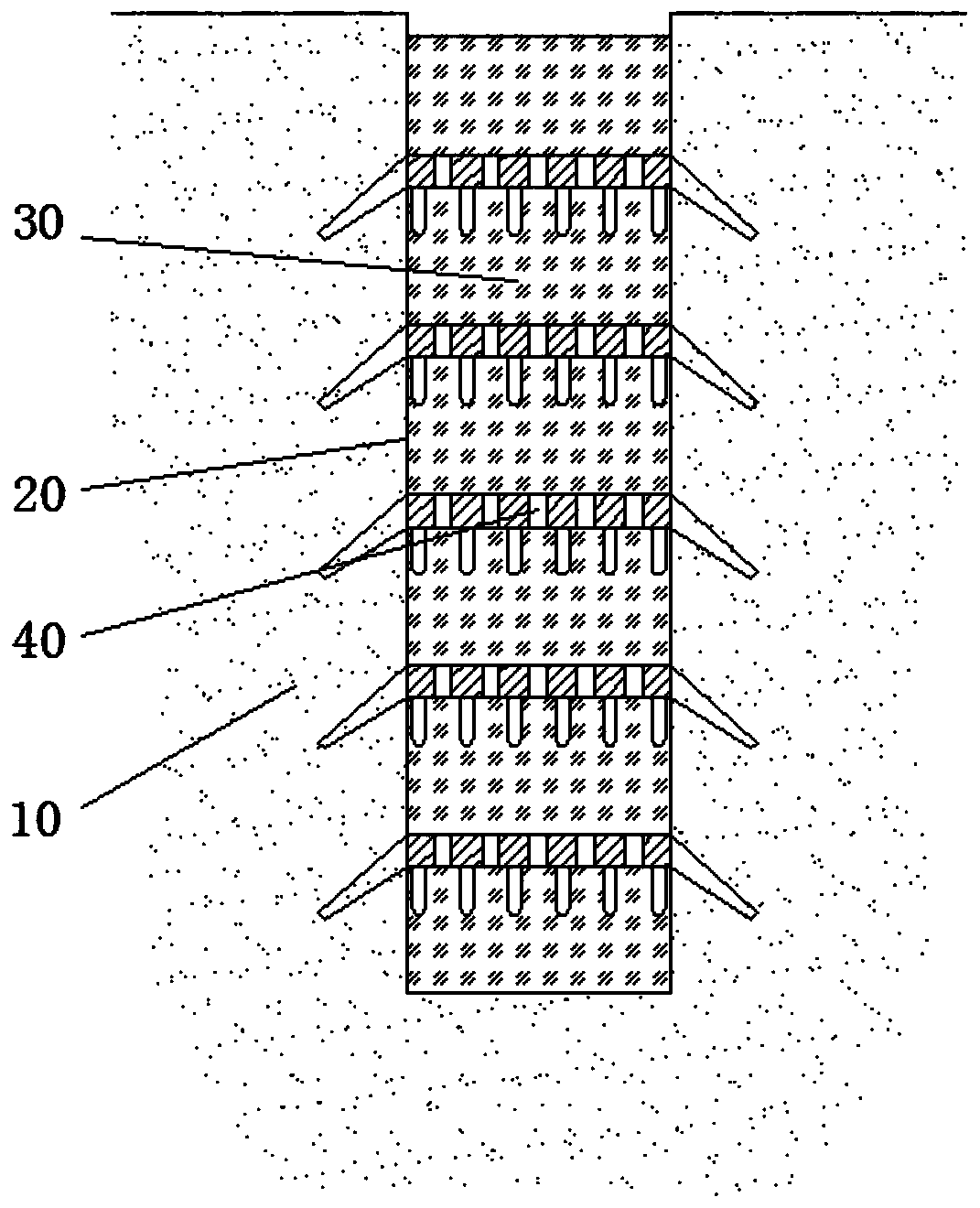

[0027] like figure 1 As shown, a kind of CFG pile described in this embodiment, is provided with CFG pile sinking pipe 20 in the soil layer 10, pours into the cement mixing layer 30 in the CFG pile sinking pipe 20, is equidistantly provided with cement mixing layer in the cement mixing layer 30 30 is an integrated positioning mechanism 40, and the positioning mechanism 40 is used to increase the cross section of the CFG pile and slow down the sinking speed of the CFG pile.

[0028] The cement mixture layer 30 and the positioning mechanism 40 are integrated, and through the effect of the positioning mechanism 40, the overall stability of the CFG pile can be slowed down, so that the overall stability of the CFG pile is higher.

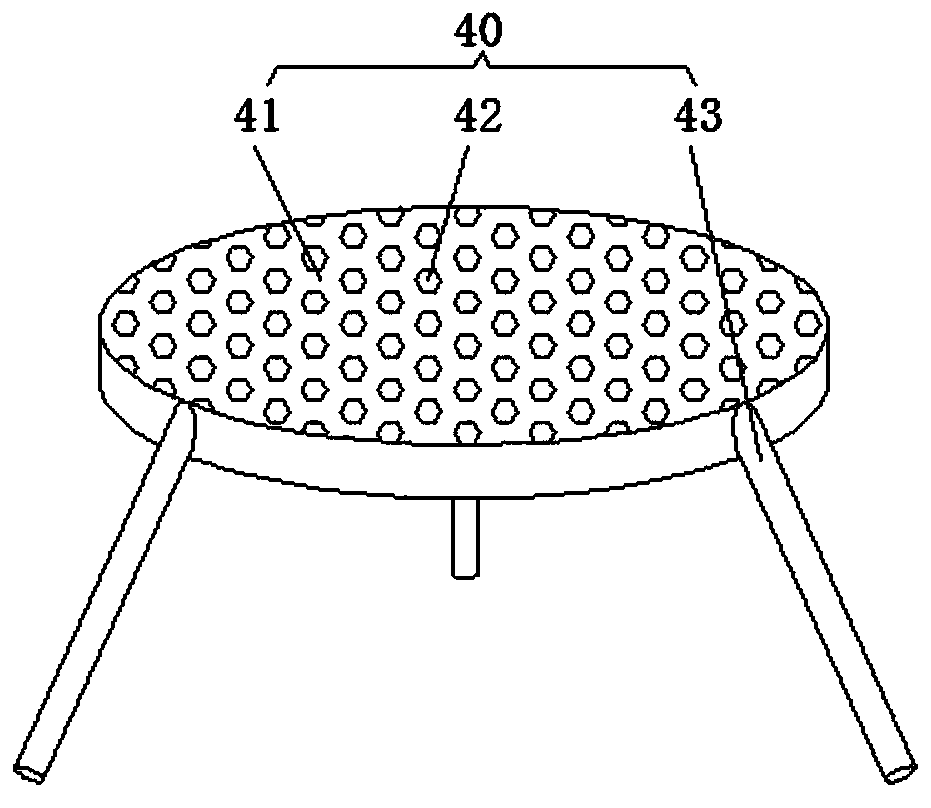

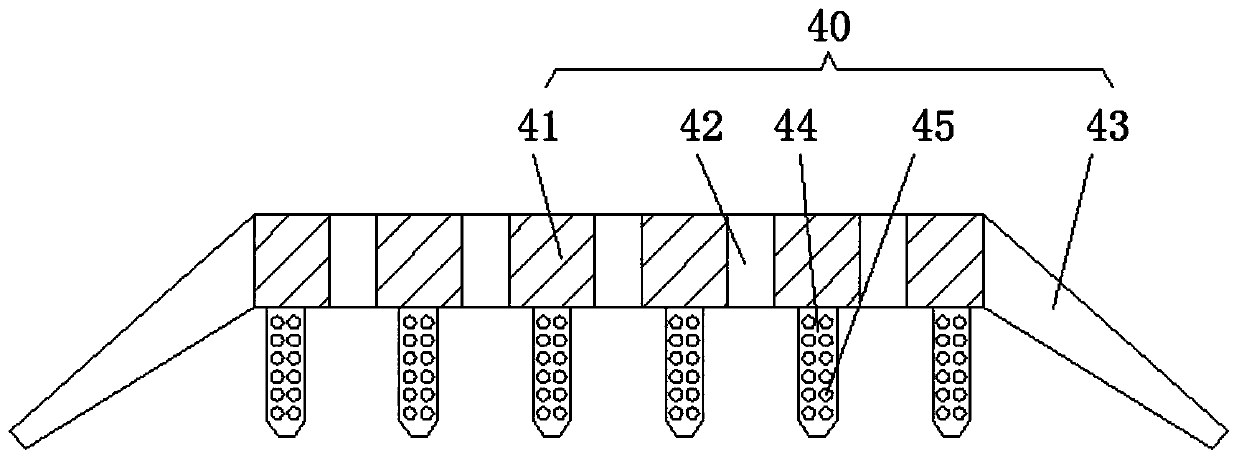

[0029] like figure 2 As shown, the positioning mechanism 40 includes a fixed circular plate 41, a through hole 42 and an inclined plane fixed column 43. The fixed circular plate 41 is uniformly provided with a through hole 42 in the vertical direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com