Trawl type garbage cleaning ship

A technology of garbage cleaning and trawling, which is used in the cleaning of open water surfaces, special-purpose ships, ships, etc., can solve the problems of low efficiency, harsh working environment, high labor intensity, etc., to improve efficiency, high cleaning efficiency, and reduce trouble. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

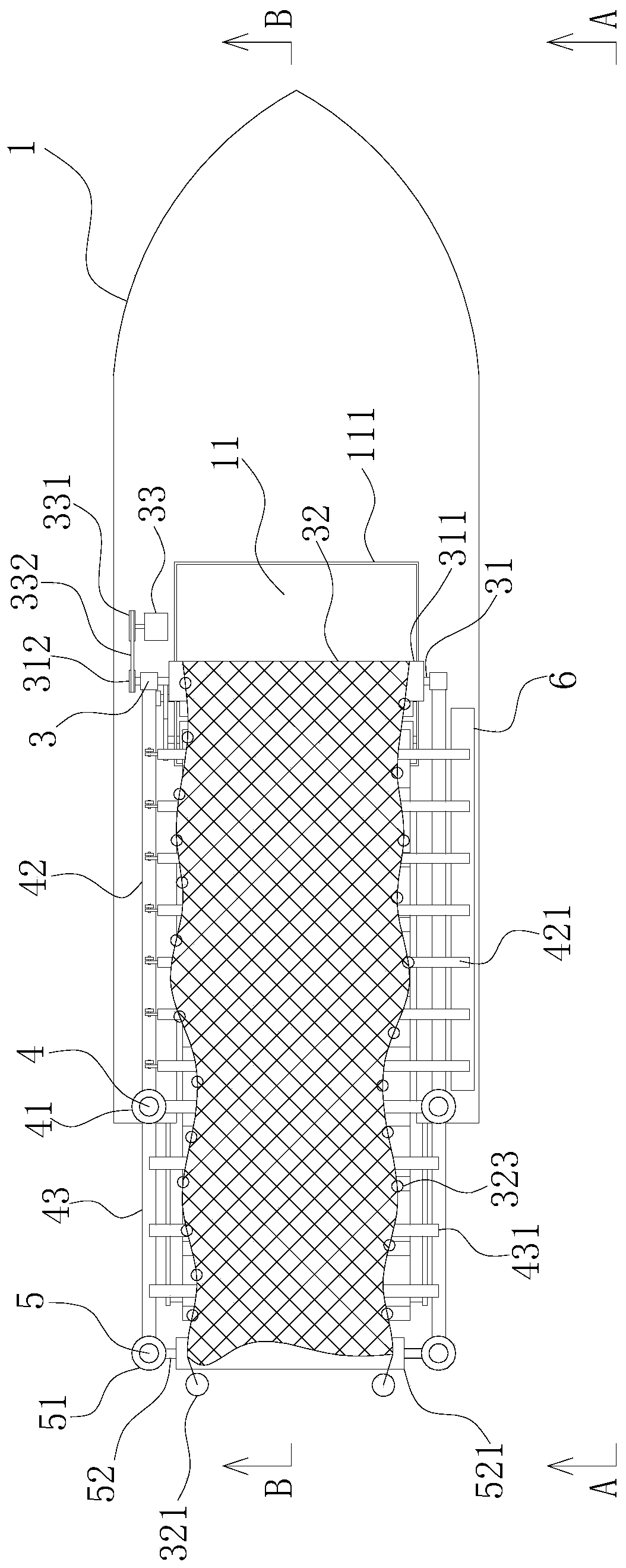

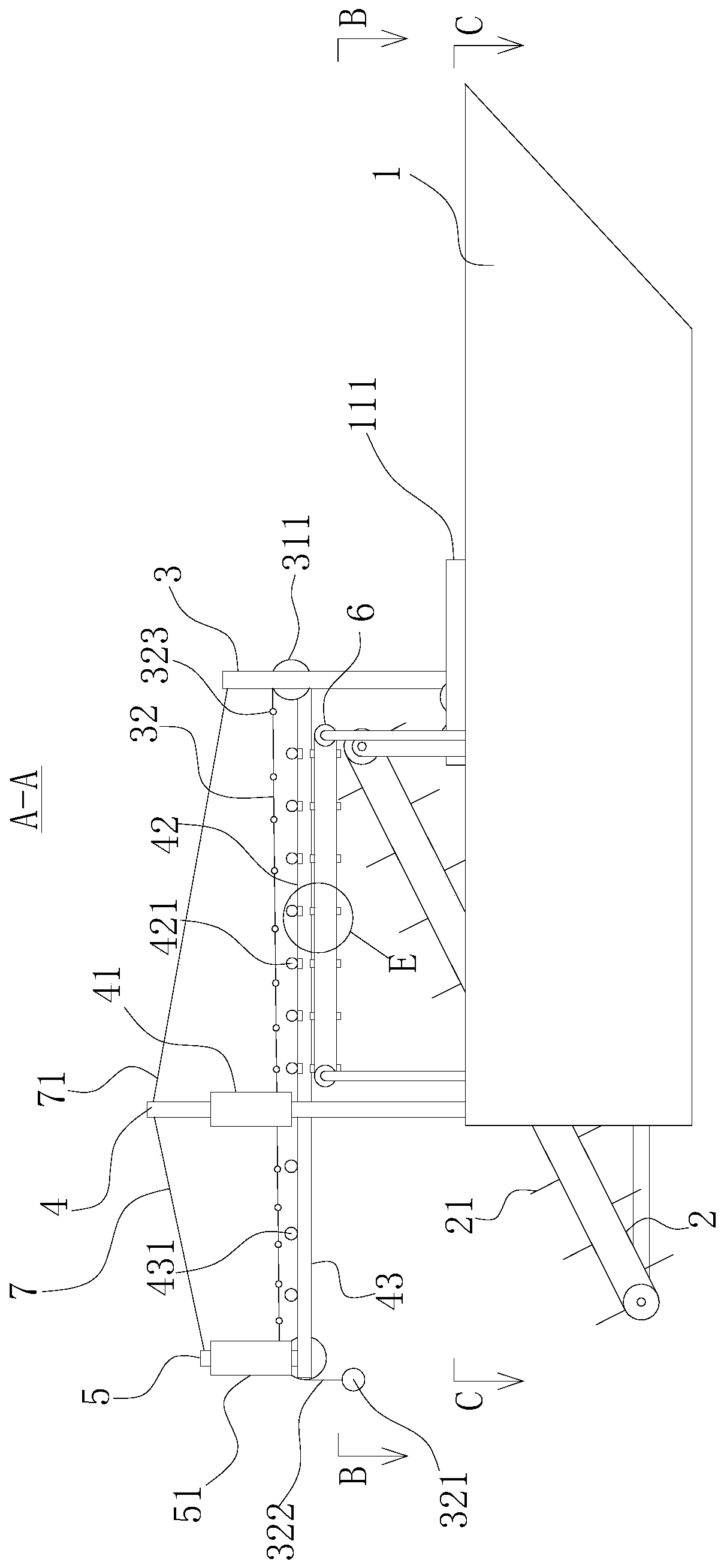

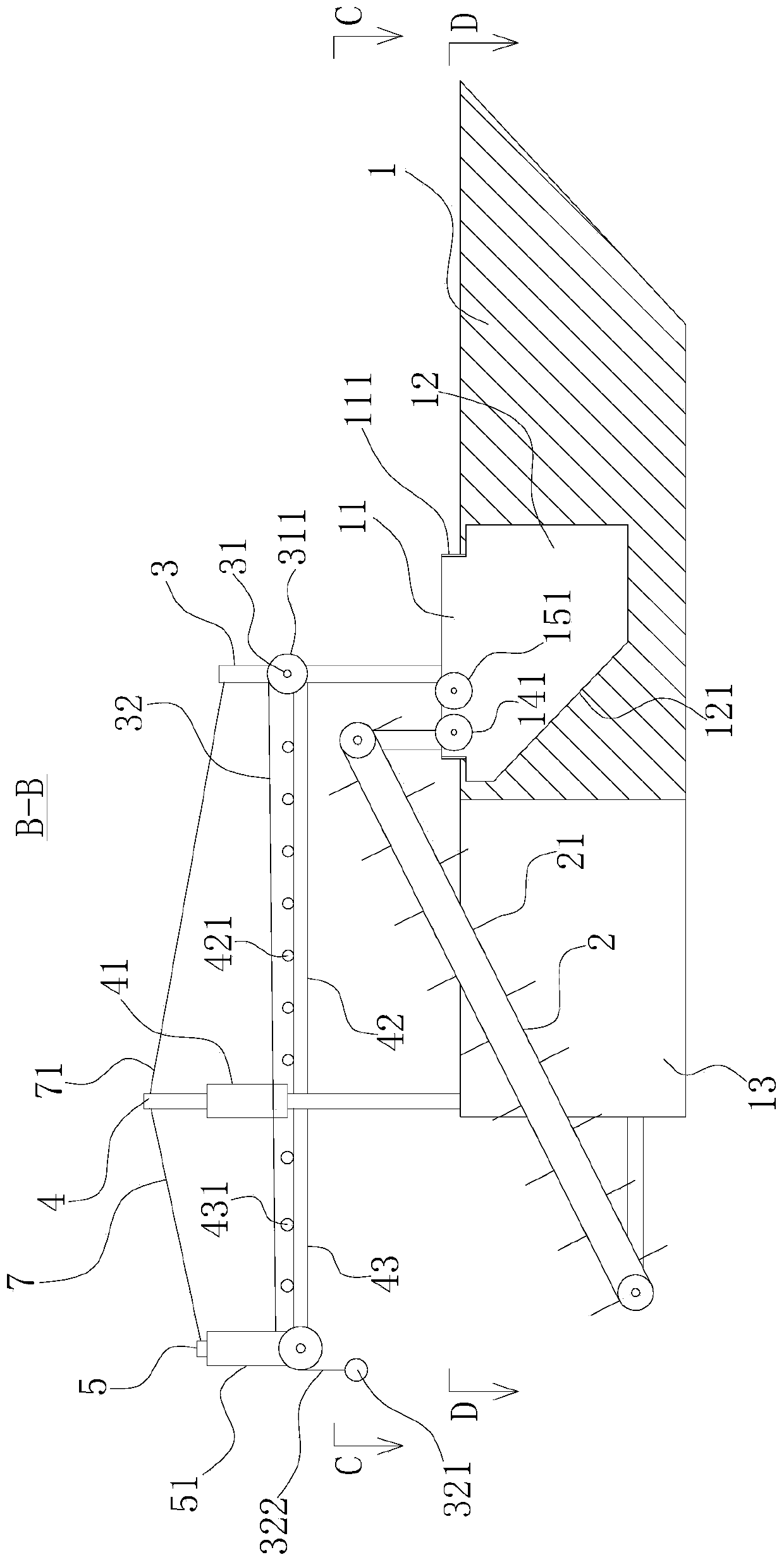

[0046] Such as Figures 1 to 6 As shown, a trawling garbage cleaning ship includes a hull structure 1, a first conveyor belt 2 and a collection mechanism.

[0047] The stern of the hull structure 1 is provided with a gap 13, and the hull structure 1 is provided with a collection cabin 12, the collection cabin 12 is located on the right side of the gap 13, and the deck surface of the hull structure 1 is provided with an opening 11, The opening 11 communicates with the collecting compartment 12 .

[0048] The first conveyor belt 2 is obliquely arranged in the gap 13, the right end of the first conveyor belt 2 protrudes upwards from the deck surface of the hull structure 1 and the end is located above the opening 12, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com