Tool changing oil cylinder mechanism and tool changing mechanism for machining center main shaft

A technology of oil cylinder and cylinder body, which is applied in the field of CNC machining center machine tool equipment, can solve the problems of spindle orientation deviation, slow spindle reset, short service life, etc., and achieve the effect of improving sealing effect, prolonging service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

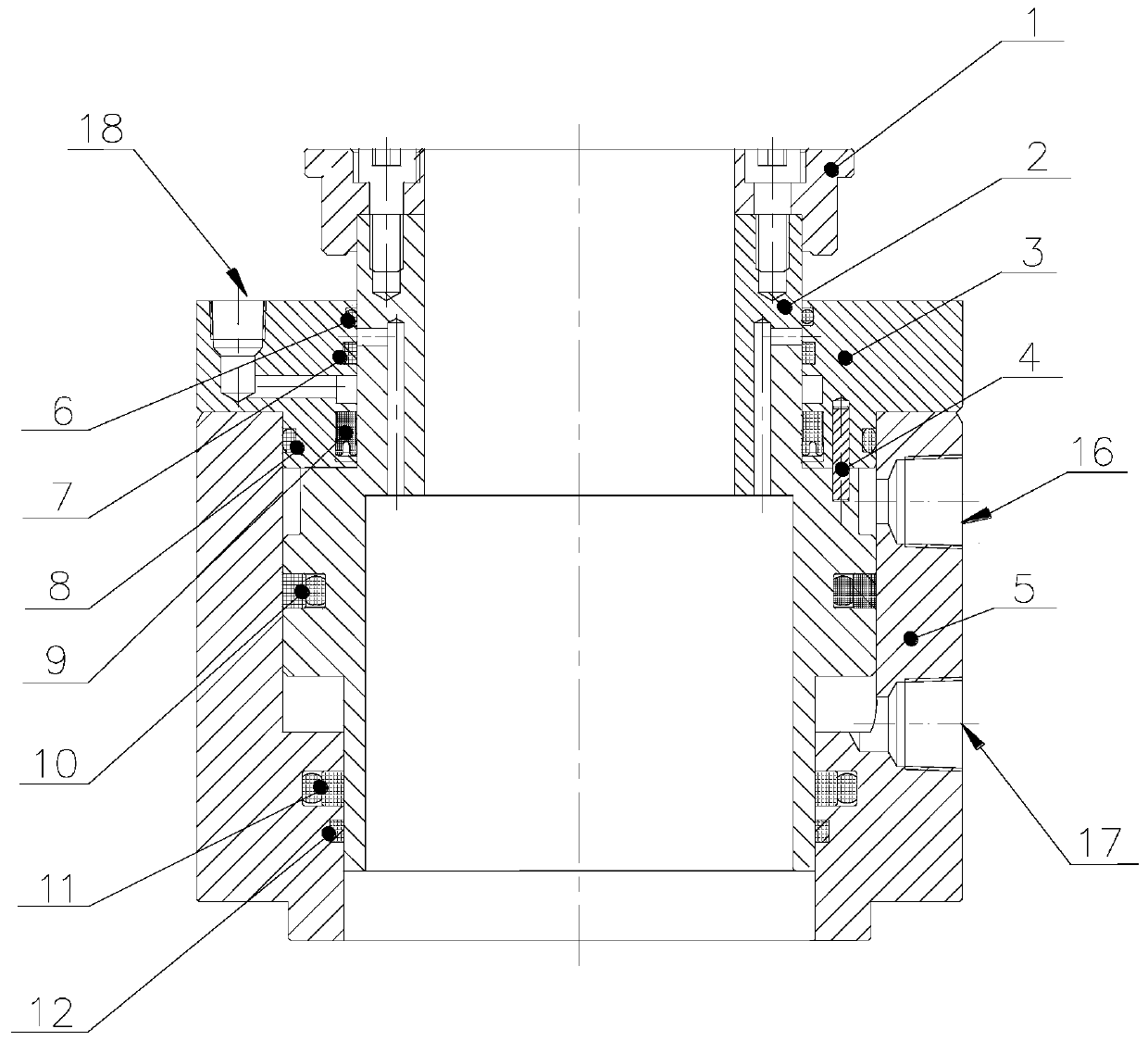

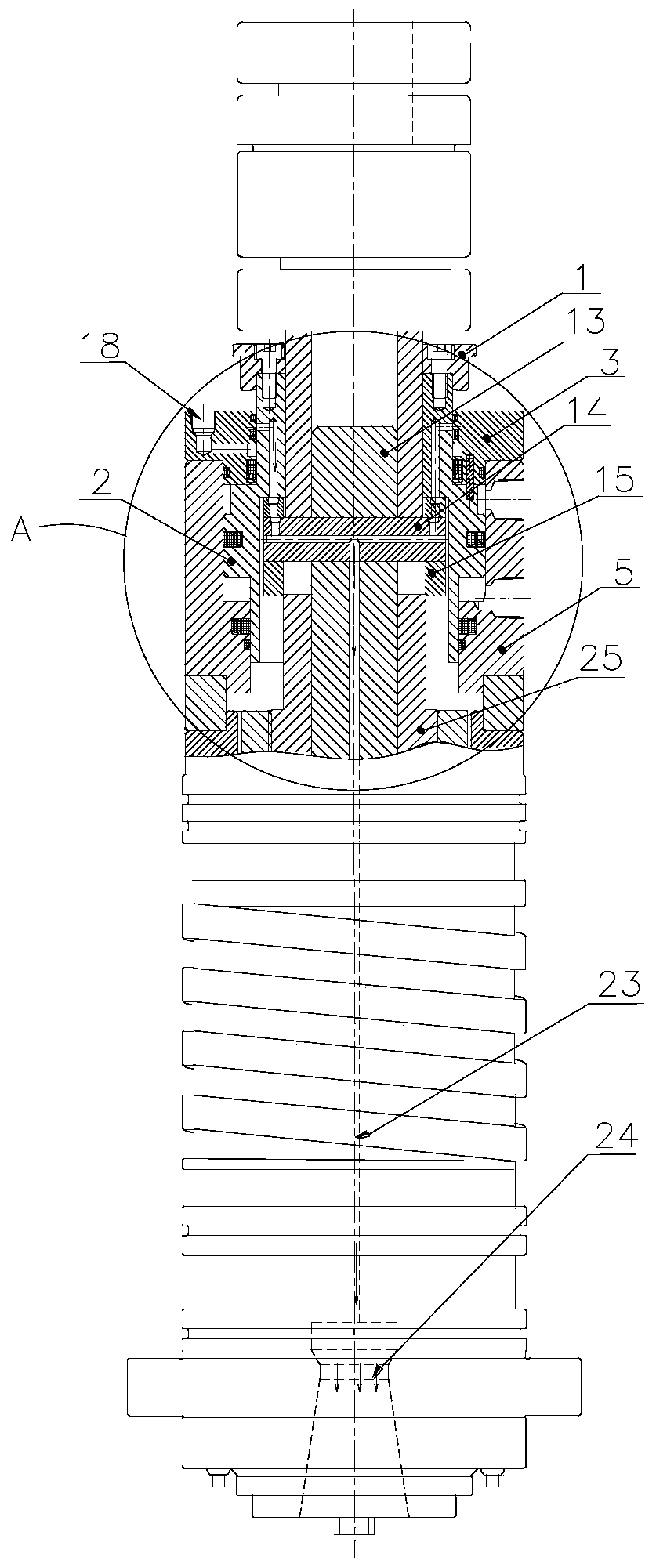

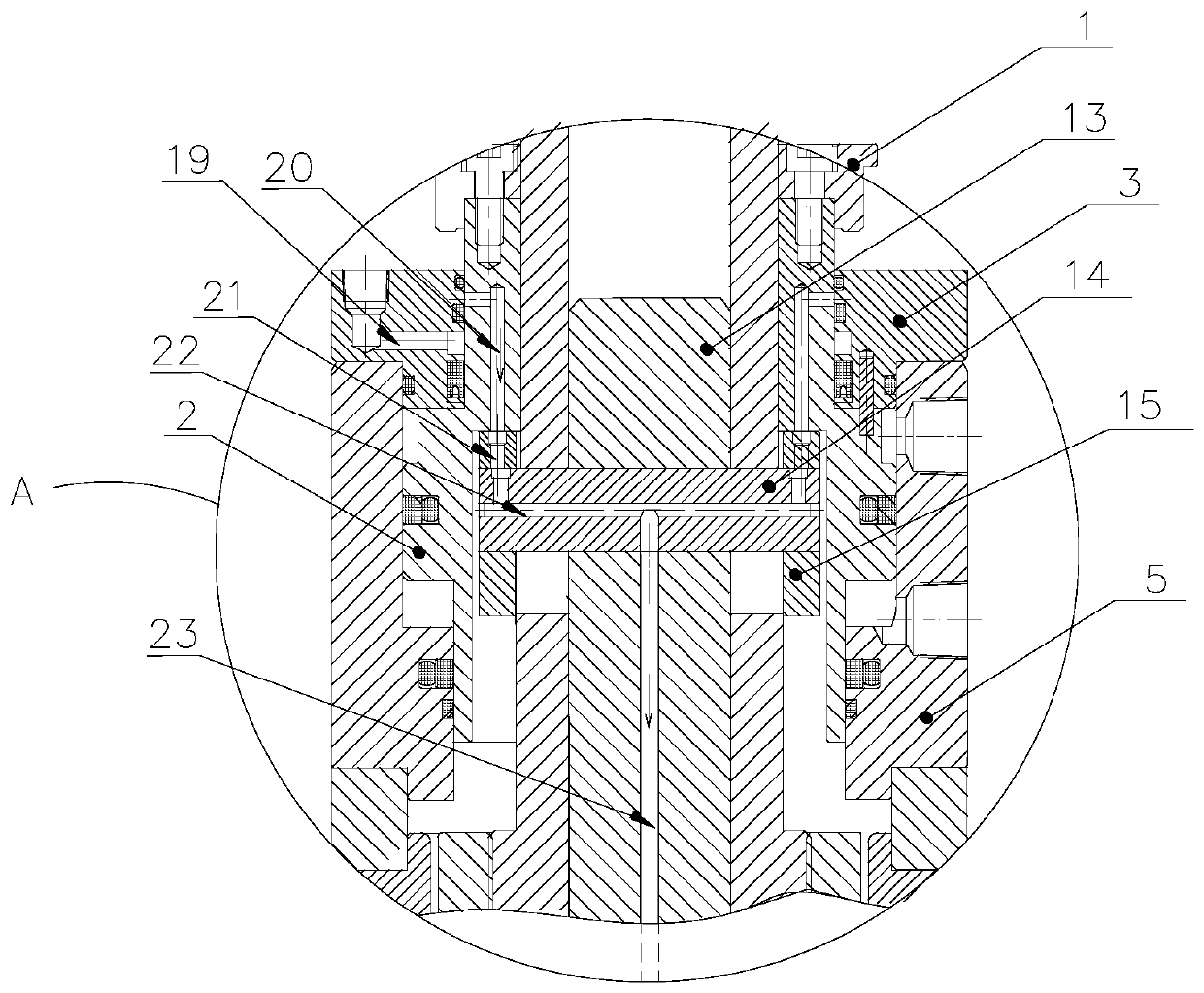

[0030] Such as figure 1 As shown, this embodiment discloses a tool change cylinder mechanism, including a cylinder body 5, a piston 2, a first guide ring 12, a top cover 1, a gland 3, an anti-rotation pin 4 and a sealing structure. cavity, the piston 2 is movably installed in the inner cavity, the first guide ring 12 is set between the piston 2 and the cylinder body 5, and is used to guide the piston 2 precisely, the top cover 1 is set on the piston 2, and the cylinder body 5 There are oil inlet 16 for unloading knife and air inlet 17 for broach. The oil inlet 16 for unloading knife and air inlet 17 for broach are respectively connected with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com