Method for producing ER5356 barreled aluminum alloy welding wires

A technology of ER5356 and aluminum alloy welding wire, which is applied in welding medium, welding equipment, transportation and packaging, etc. It can solve the problems of scrapped welding wire, loose welding wire arrangement, easy jamming and confusion, etc., and achieves tight welding wire and smooth wire output , No jamming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

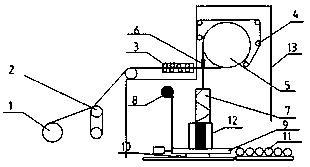

[0024] Such as figure 1 As shown, the production device of the ER5356 barreled aluminum alloy welding wire in this embodiment includes a pay-off machine 1, a tension mechanism 2 is arranged behind the pay-off machine 1, a straightening mechanism 3 is arranged behind the tension mechanism 2, and a straightening mechanism 3 is arranged behind the straightening mechanism 3. A traction mechanism 4 is provided, and the traction mechanism 4 includes a flywheel device 5 and 5 conveying rollers arranged near the flywheel device 6. A wire feeding mechanism 7 is provided below the traction mechanism 4, and a meter gauge is also provided between the traction mechanism and the wire feeding mechanism. device. The pulling mechanism 4 pulls the welding wire behind the straightening mechanism 3 into the meter counting device 6 .

[0025] The wire feeding mechanism 7 is arranged on the welding wire cylinder 12, the welding wire cylinder 12 is arranged on the rotary table 9, the rotary table 9...

Embodiment 2

[0030] The device of this embodiment is the same as that of Embodiment 1.

[0031] The present embodiment is based on the above-mentioned production method of ER5356 barreled aluminum alloy welding wire, and the welding wire is ER5356 aluminum alloy welding wire with a tensile strength of 505 MPa and a diameter of 1.2 mm. The barrel loading line speed is controlled to 8m / s, the tension machine pressure is controlled to 0.2MPa, and the straightening mechanism 4 adopts 2 sets of 22-wheel two-way adjustment straighteners. The diameter of the barrel welding wire ring is 435mm. There are three levels of vibration during the welding wire loading process. The starting weight of each level of vibration is: 3kg, 15kg, and 25kg, the amplitudes are 2, 4, and 5, and the duration of each vibration is 5s. The weight of the welding wire in barrel is 30kg.

[0032] Through the implementation of the above-mentioned embodiment, the welding wire loaded into the welding wire barrel is not only t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com