Micro-pressure filtering device in front of pump

A filter device, a technology in front of a pump, applied in the directions of filtration separation, filtration circuit, fixed filter element filter, etc., can solve the problems of high cost and energy consumption, consuming human resources, low filtration efficiency, etc., and achieves convenient and quick disassembly and assembly, Improve filtration efficiency and good filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

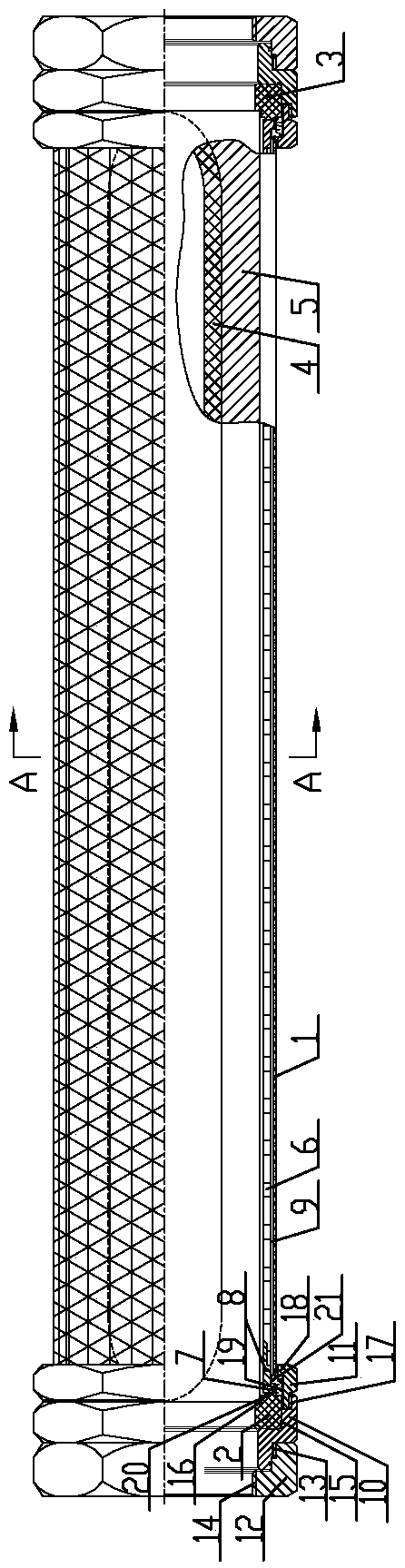

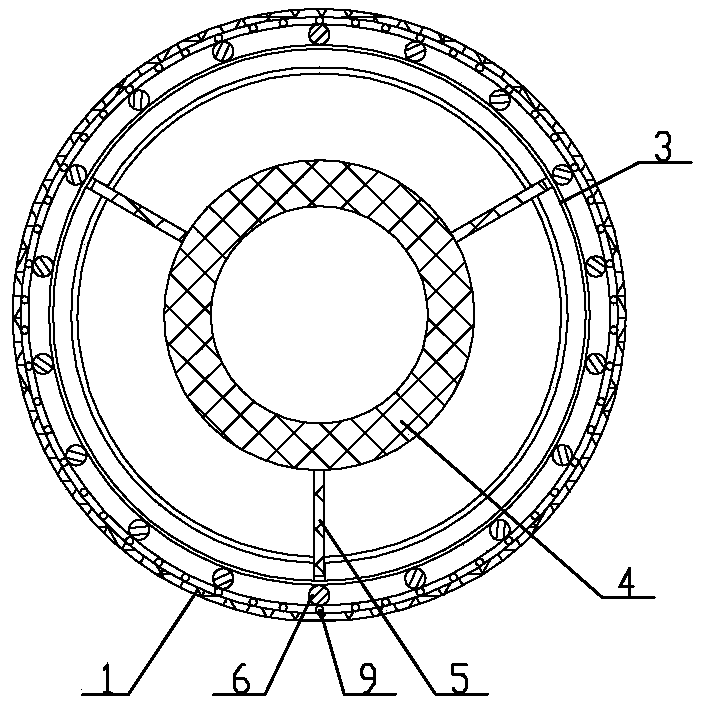

[0022] Embodiment 1: as figure 1 As shown in -3, the micro-pressure filter device in front of the pump includes a filter screen cylinder 1, a left joint, a right joint, a left water distribution seat 2, a right water distribution seat 3 and a water separator, and the filter screen cylinder 1 is arranged horizontally along the axis Horizontal cylindrical cylinder, the left end of the filter cylinder 1 is fixed with a left joint that can be connected to the left water inlet pipeline, the right end of the filter cylinder 1 is fixed with a right joint that can be connected with the right sewage pipeline, the left joint or the filter cylinder 1 The center of the inner cavity at the left end is fixed with the left water distributor 2, and the center of the inner cavity at the right end of the right joint or filter cylinder 1 is fixed with the right water distributor 3, and the water distributor is installed through the left water distributor 2 and the right water distributor 3 In th...

Embodiment 2

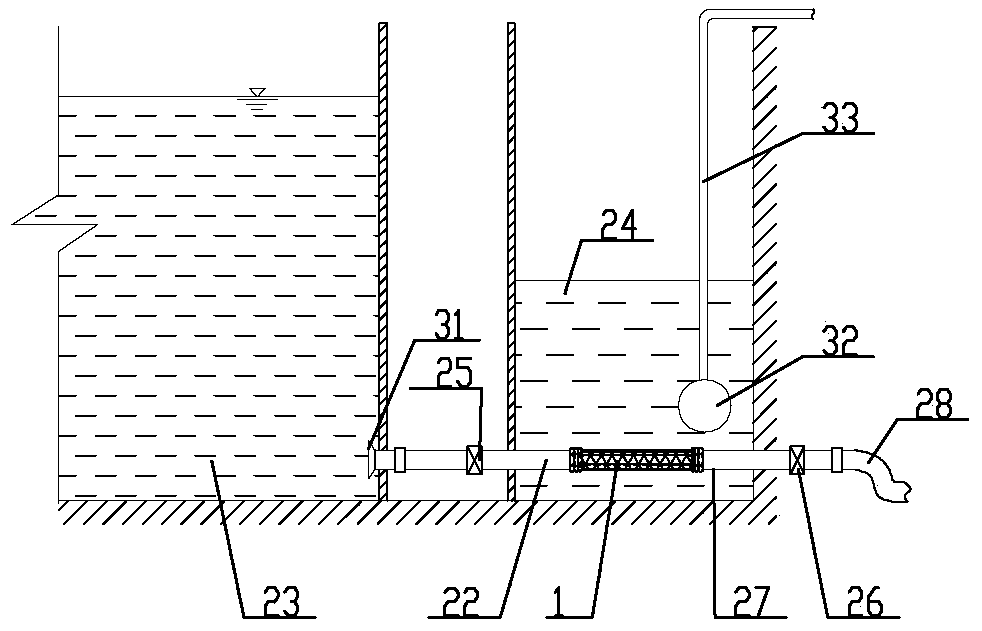

[0031] Embodiment 2: as Figure 4 As shown, a filter housing 29 is installed on the outside of the filter screen cylinder 1, and the inside of the filter housing 29 has a filter chamber surrounding the filter screen cylinder 1. The left part of the filter housing 29 is equipped with a left joint, and the filter housing The right part of the body 29 is equipped with a right joint, and the filter screen cylinder 1 isolates the inner chamber of the left joint and the inner chamber of the right joint from the filter cavity, and the bottom of the filter housing 29 is provided with a water supply port 30, and the water supply port 30 The cavity is connected with the filter chamber, and the left joint includes a joint body 10 and a pipe connection screw sleeve 12. An external groove 13 with a joint external thread is arranged on the left side of the joint body 10, and the pipe connection screw sleeve 12 passes through the outside of the joint. The thread is fixedly installed in the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com