An oled folding or windable screen and its manufacturing process

A manufacturing process and screen technology, applied to the structure of telephone sets, sub-office equipment, electrical components, etc., can solve problems such as deformation of the adhesive layer, separation of the adhesive layer and the screen, and exposure of dust, so as to reduce the size of the soft rubber and avoid sticking at the edges dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

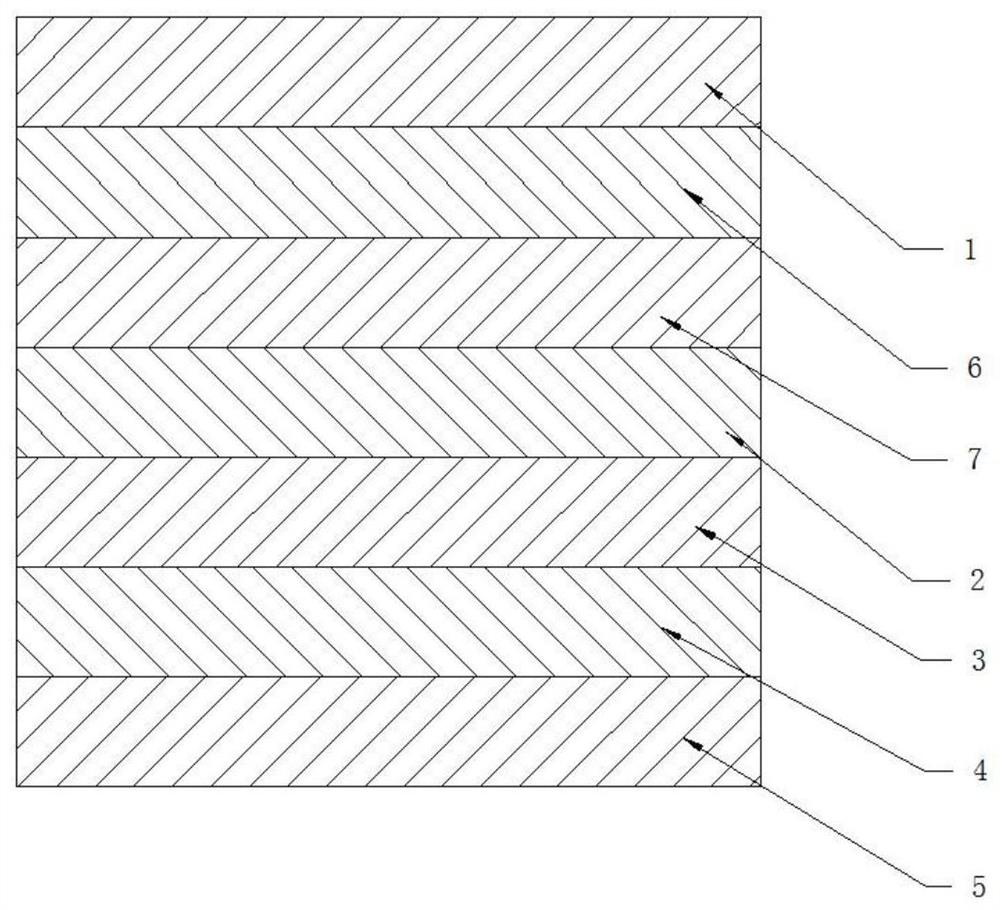

[0038] Such as figure 1 , 2 As shown in , 3, 4, and 5, an OLED folding or windable screen and its manufacturing process, when the screen is folded, it includes an OLED display layer, a soft glue layer, a printing layer, a base material, and a hardened layer;

[0039] Folding screen, the inward folding structure of the screen is: a hardened layer is provided above the substrate, a printing layer is provided below the substrate, a soft rubber layer is provided below the printing layer, and an OLED is provided below the soft rubber layer. display layer;

[0040] Folding screen, the outer folding structure of the screen is: a hardened layer is provided under the base material, a printing layer is provided above the base material, a soft rubber layer is provided above the printing layer, and an OLED is provided above the soft rubber layer. display laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com