High-precision linear motor one-time alignment platform

A technology of linear motors and alignment platforms, applied in electrical components, electromechanical devices, propulsion systems, etc., can solve problems such as increasing production costs, prolonging alignment work time, and unreachable alignment of displacement strokes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

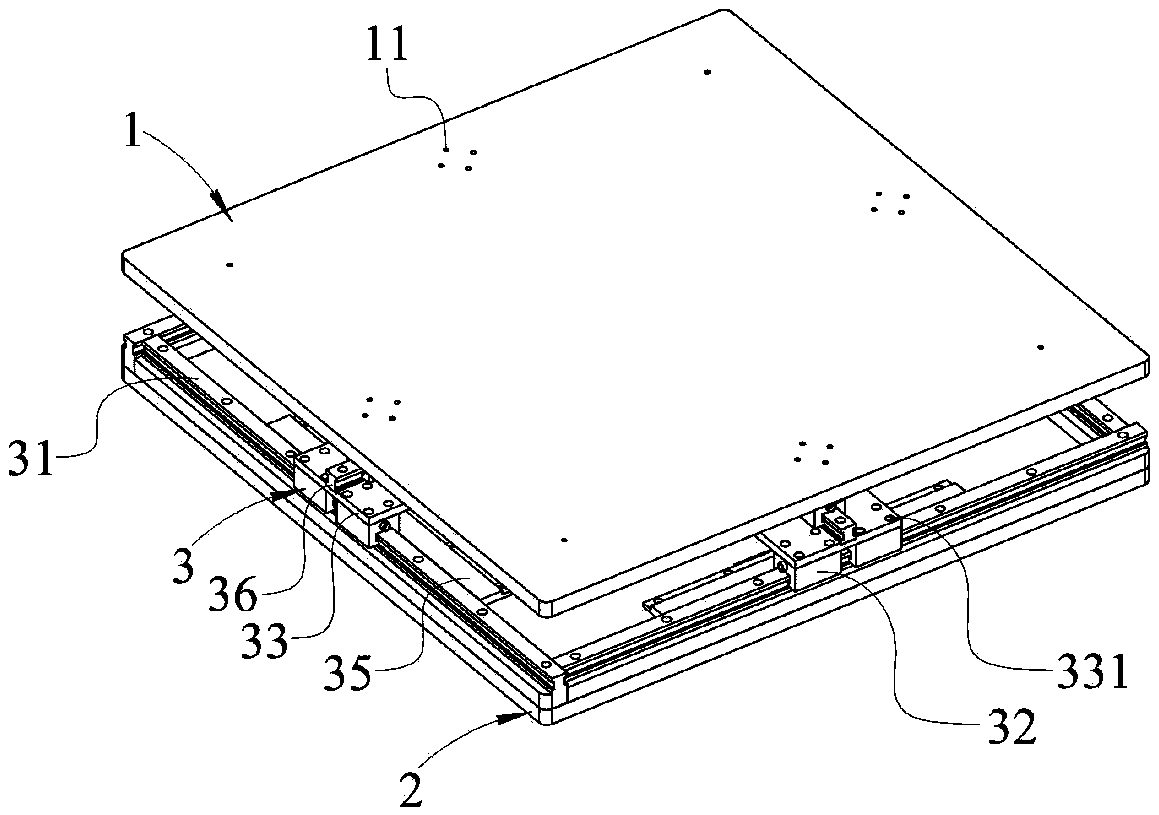

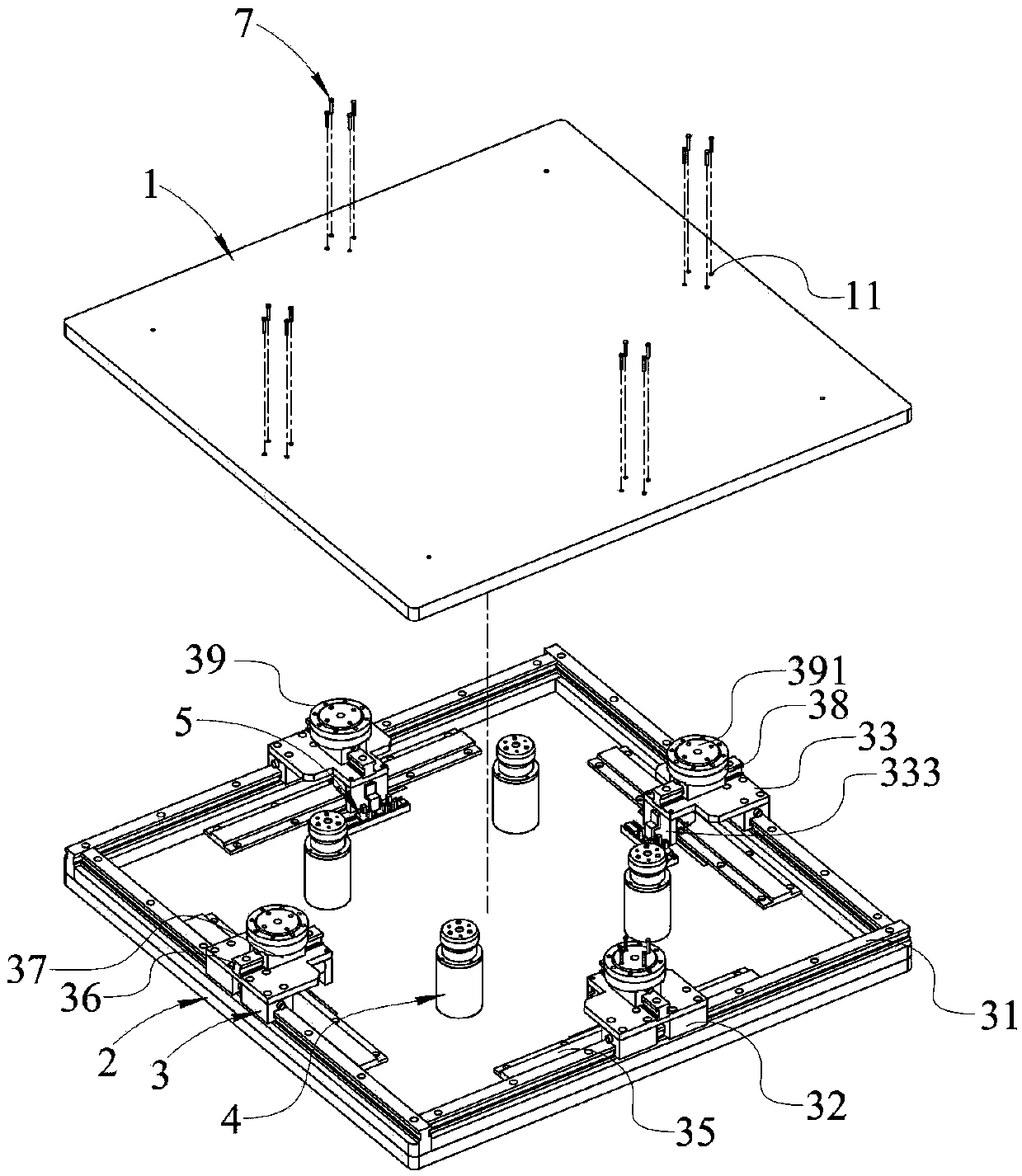

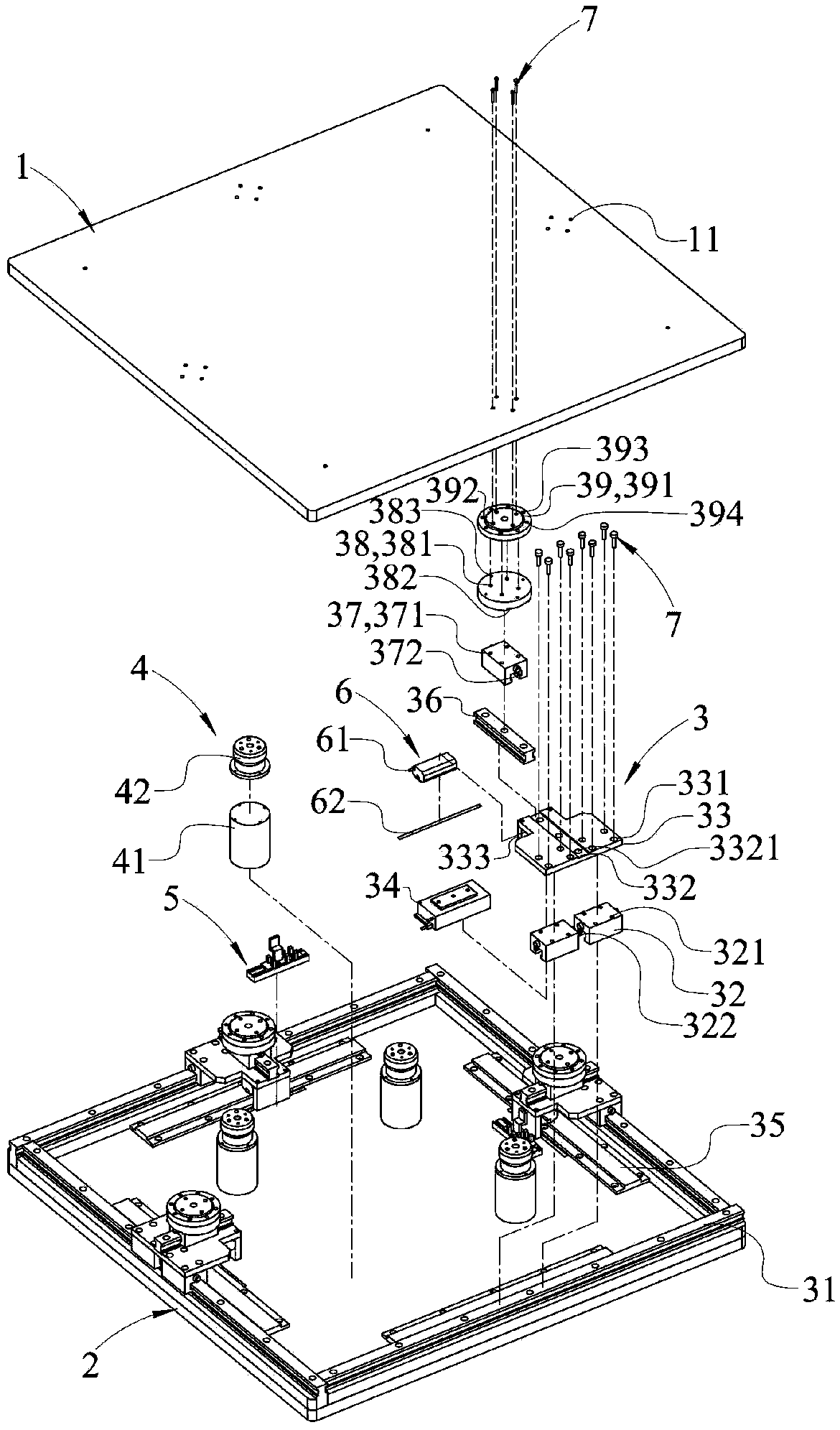

[0015] The present invention is a high-precision linear motor primary alignment platform. Among the specific embodiments of the present invention and its components illustrated in the accompanying drawings, all about front and rear, left and right, top and bottom, upper and lower, and horizontal References to vertical are used for convenience of description only, and do not limit the invention, nor limit its components to any position or spatial orientation. The dimensions specified in the drawings and instructions can be changed according to the design and requirements of the specific embodiments of the present invention without departing from the scope of the patent application of the present invention;

[0016] See Figure l to image 3 As shown, a high-precision linear motor primary alignment platform, its structure includes: a platform 1, a platform base 2, a plurality of linear motor drive components 3, a plurality of electromagnets 4, a plurality of limit switches 5 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com