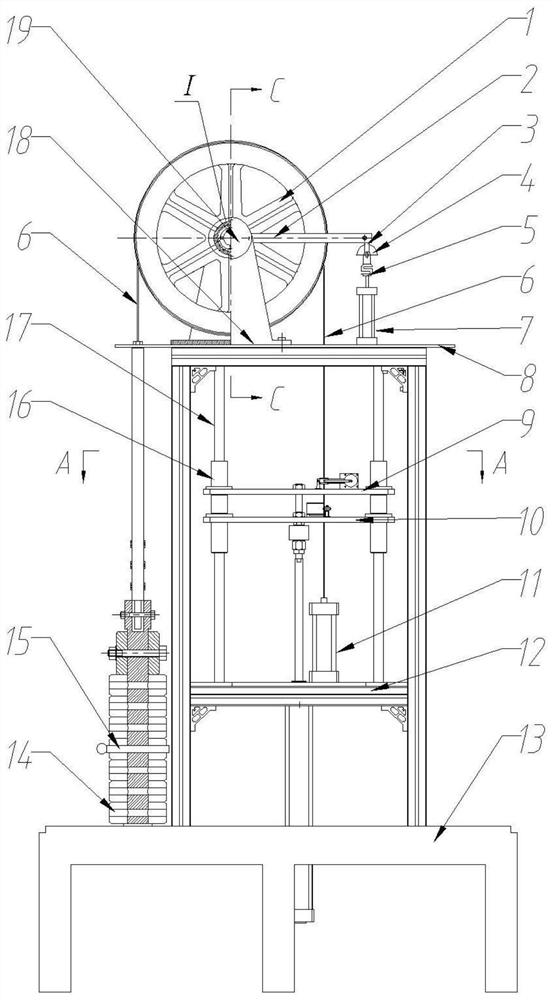

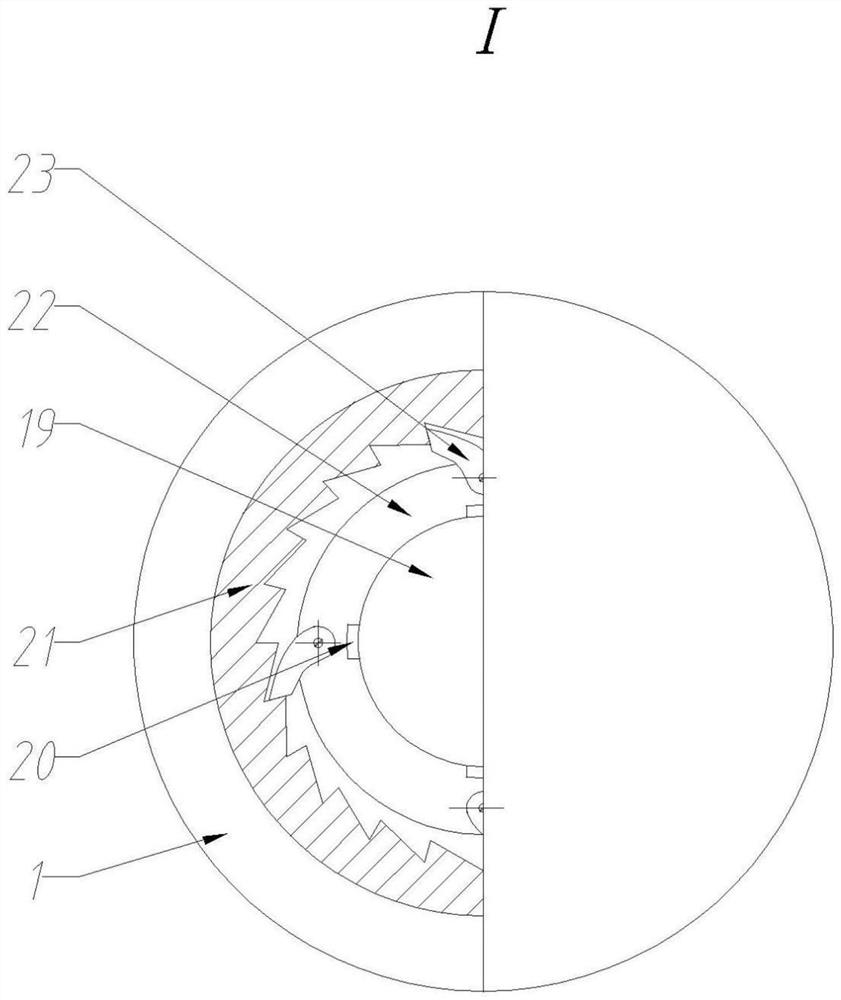

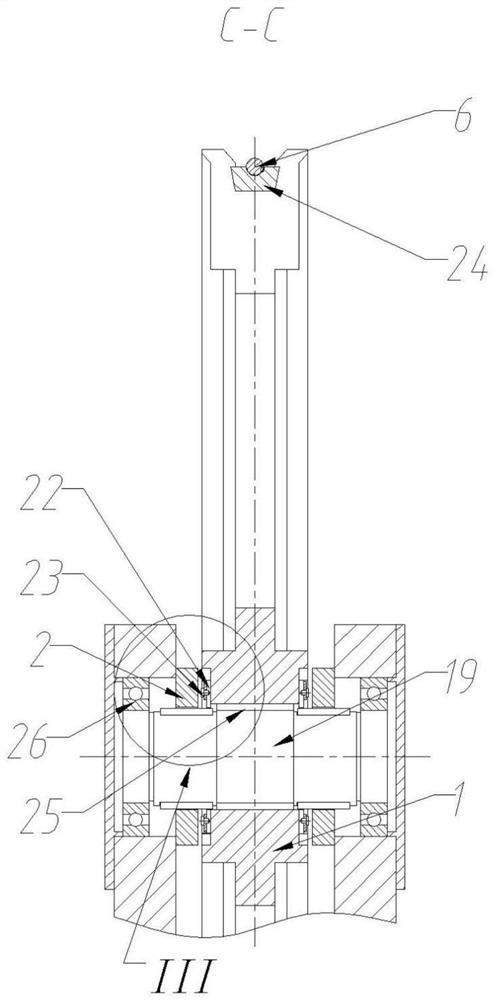

A friction loss experimental device and method under multi-directional vibration of steel wire rope and liner

A technology of friction loss and experimental equipment, which is applied in the field of mining machinery and equipment, can solve the problems of not considering the lateral vibration, the inability to adjust the longitudinal excitation, and the difference, and achieve the effect of comprehensive vibration mode, improved reliability and stability, and simple parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0086] The difference between the experimental device of this embodiment and the first embodiment is that the predetermined excitation frequency is 25 Hz, the weight of the counterweight 14 is 1000 kg, and the predetermined excitation amplitude is 0.5 mm.

Embodiment 3

[0088] The difference between the experimental device of this embodiment and the second embodiment is that the predetermined excitation frequency is 50 Hz, the weight of the counterweight 14 is 2000 kg, and the predetermined excitation amplitude is 2 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com