Exhaust components, compressors and air conditioners

A technology of compressors and components, applied in the field of compressors, can solve the problems of affecting the performance of compressors, unfavorable low-noise design of compressors, and high cost, and achieve the effect of reducing collision noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

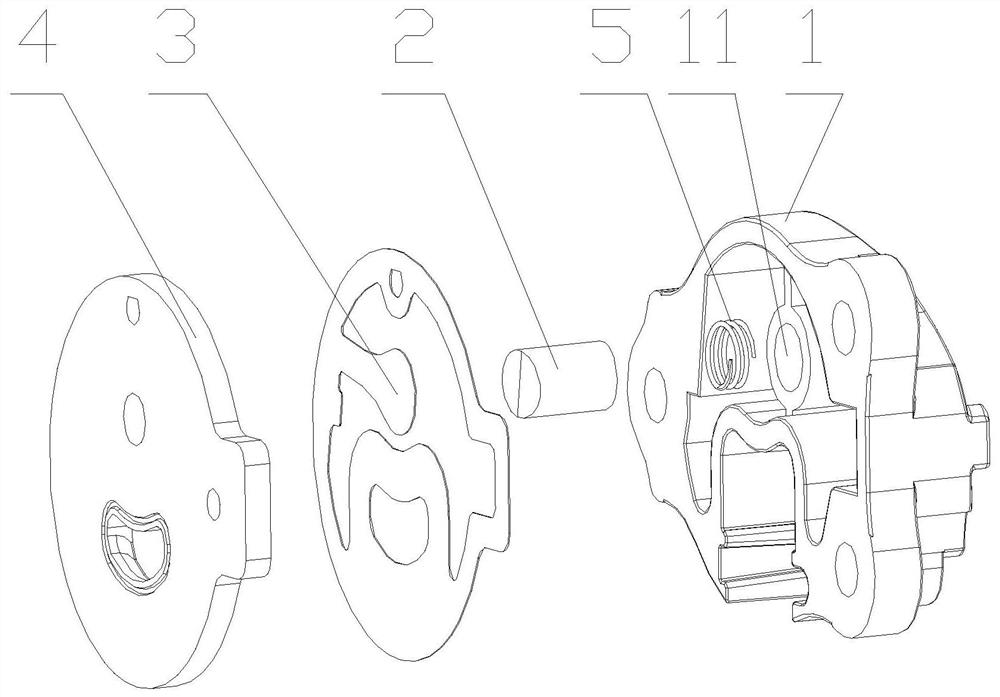

[0026] see in conjunction Figure 2 to Figure 5 As shown, according to an embodiment of the present application, an exhaust assembly includes at least

[0027] fixed seat;

[0028] The exhaust valve piece 3 is fixed on the fixed seat and elastically covers the exhaust port;

[0029] One end of the lift piece 2 abuts against the exhaust valve plate 3 , and the lift piece 2 is integrally and movably arranged on the fixed seat along the movement direction of the exhaust valve plate 3 .

[0030] The lifting part 2 that can move as a whole is adopted, and the exhaust valve plate 3 can push the lifting part 2 when exhausting. Since the lifting part 2 is a movable part, its movement height can be changed, so it can adapt to different working conditions Exhaust problem. In addition, since the lift member 2 and the exhaust valve plate 3 are in abutting state, no collision will occur when the exhaust valve plate 3 is opened, and the collision noise is eliminated. The lift piece 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com