Cam-actuated engine hydraulic valve control

A control device and engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of valve seat ring impact, inability to change valve lift and opening duration, etc., to achieve flexible change, simple structure, The effect of improving power and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

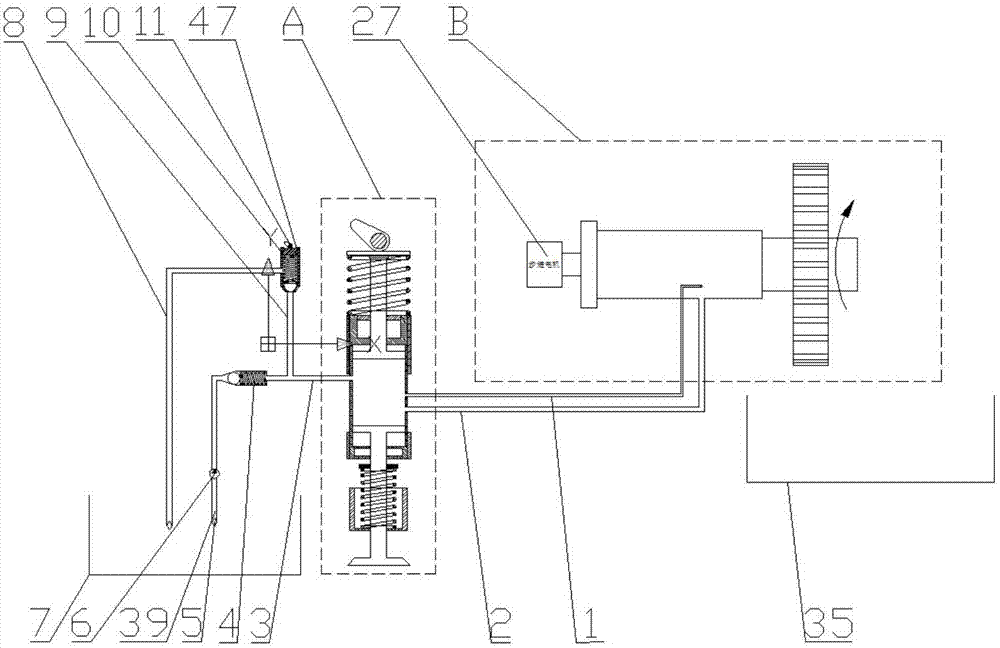

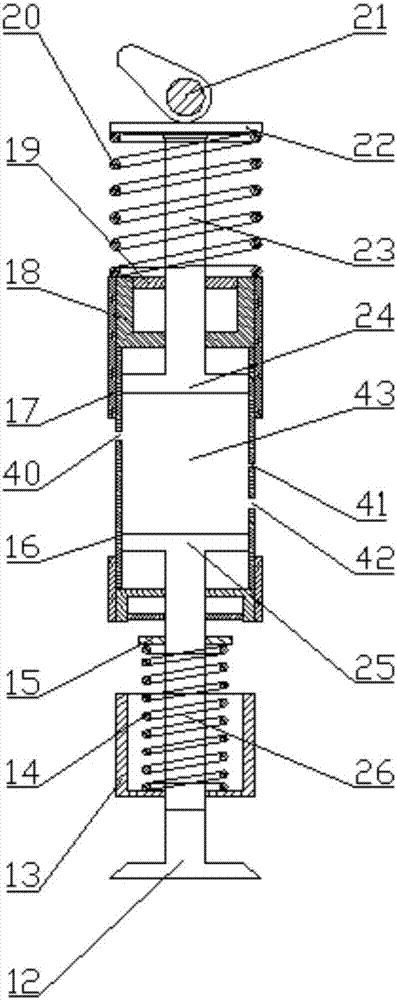

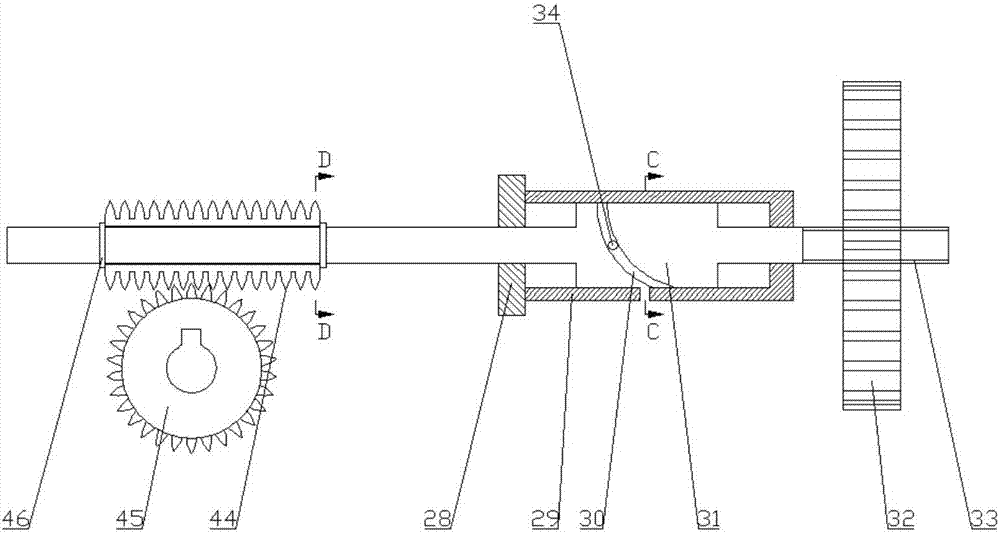

[0040] refer to figure 1 , the present invention consists of a hydraulic piston valve group A, a valve opening duration control mechanism, a valve seating buffer mechanism B, a valve lift control mechanism (including a one-way valve II10, a cam I11), an oil pipe I1, an oil pipe II2, an oil pipe III3, a one-way Valve Ⅰ4, filter 5, oil pump 6, oil tank Ⅰ7, oil pipe Ⅳ8, oil pipe Ⅴ9, oil tank Ⅱ35;

[0041] Oil tank Ⅰ7 and oil tank Ⅱ35 are common oil tanks for storing hydraulic oil.

[0042] The filter 5 is installed between the oil tank I7 and the oil pump 6, and its function is to filter the hydraulic oil sucked into the oil pump 6 to ensure the cleanliness of the hydraulic oil in the entire supply system.

[0043] The main function of the check valve Ⅰ4 is to separate the high pressure system from the low pressure system, which can not only supply oil to the high pressure syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com