Construction technology for installing directly-buried-section reinforced concrete drainage pipelines

A technology for reinforced concrete and drainage pipes, which is applied in the sewer system, waterway system, water supply device, etc., can solve problems such as low construction efficiency, and achieve the effect of improving construction efficiency, realizing controllability and reducing erection time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

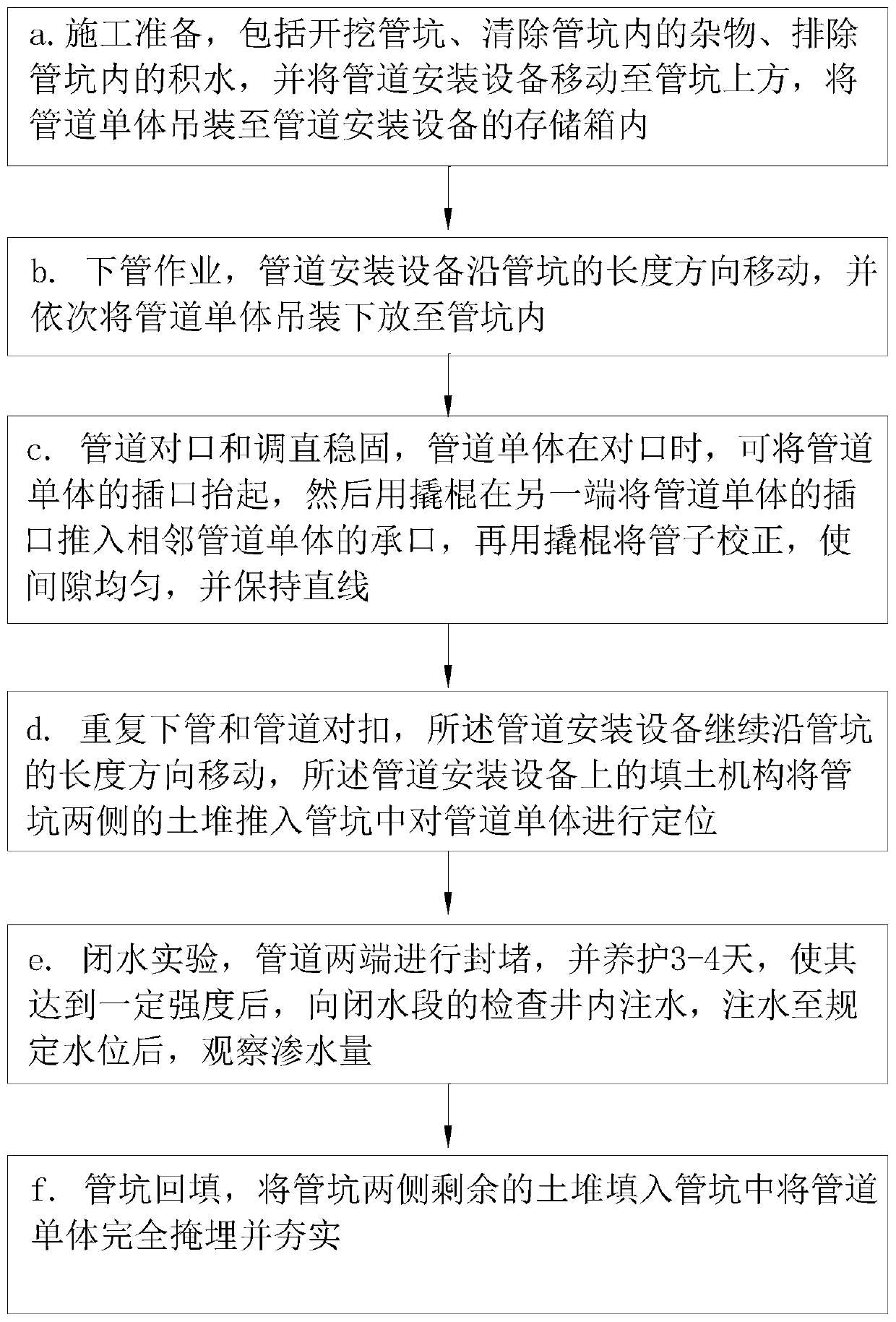

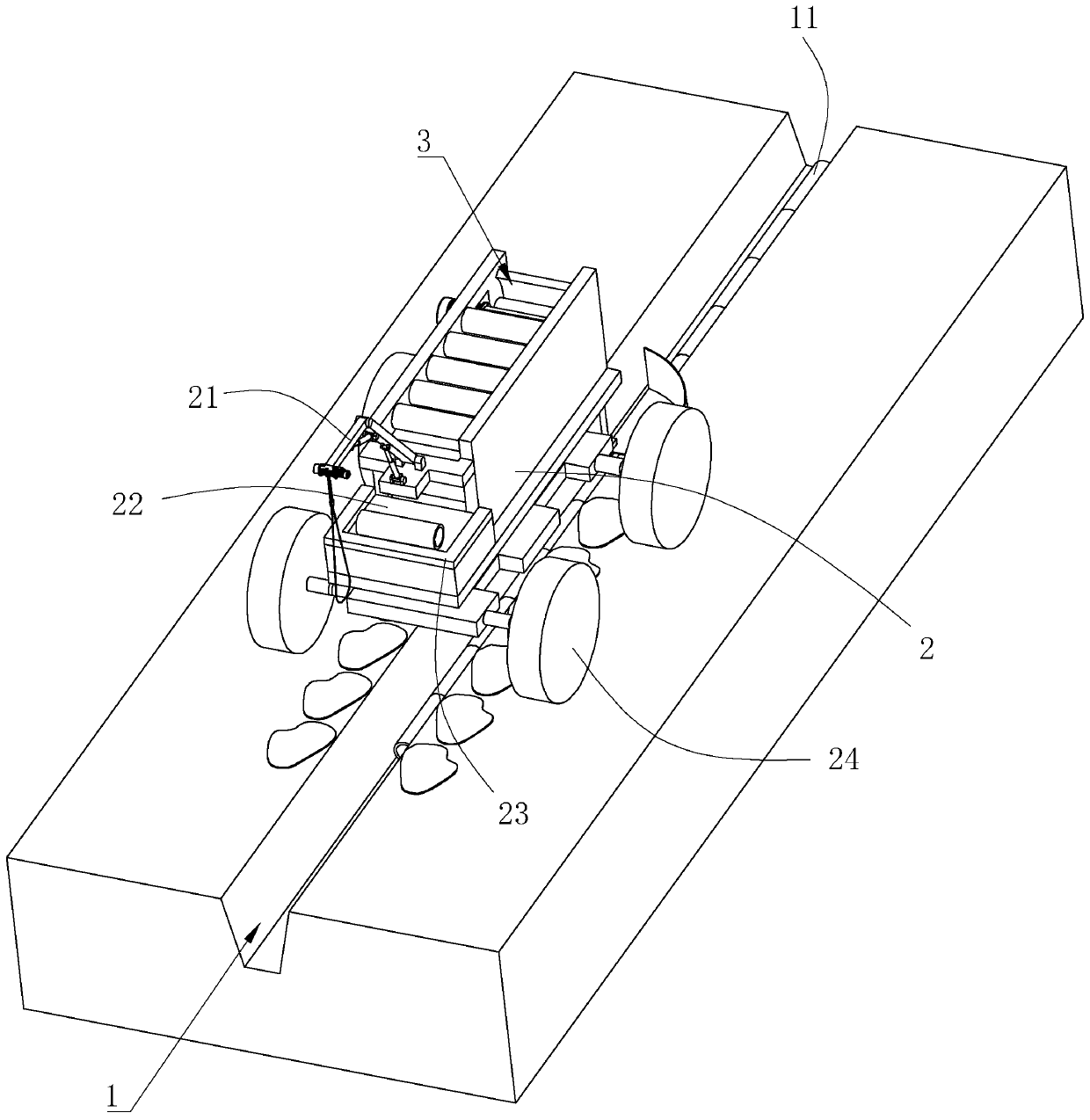

[0042] Such as Figure 1 to Figure 2 As shown, a kind of direct buried section reinforced concrete drainage pipeline installation and construction technology disclosed by the present invention comprises the following steps:

[0043] a. Construction preparation, including excavating the pipe pit 1, clearing the sundries in the pipe pit 1, removing the accumulated water in the pipe pit 1, moving the pipeline installation equipment to the top of the pipe pit 1, and hoisting the pipeline monomer 11 to the pipeline In the storage box 3 where the equipment is installed;

[0044] b. For the pipe lowering operation, the pipe installation equipment moves along the length direction of the pipe pit 1, and the pipe unit 11 is hoisted and lowered into the pipe pit 1 in sequence;

[0045] c. The pipe is aligned and straightened firmly. When the pipe unit 11 is aligned, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com