Manufacturing method of welding mold for initial support grid steel frame in mine method

A technology of grid steel frame and welding mold, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. The position of the bolt holes in the plate is difficult to align and other problems, so as to shorten the exposure time, shorten the erection time, and reduce the safety risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

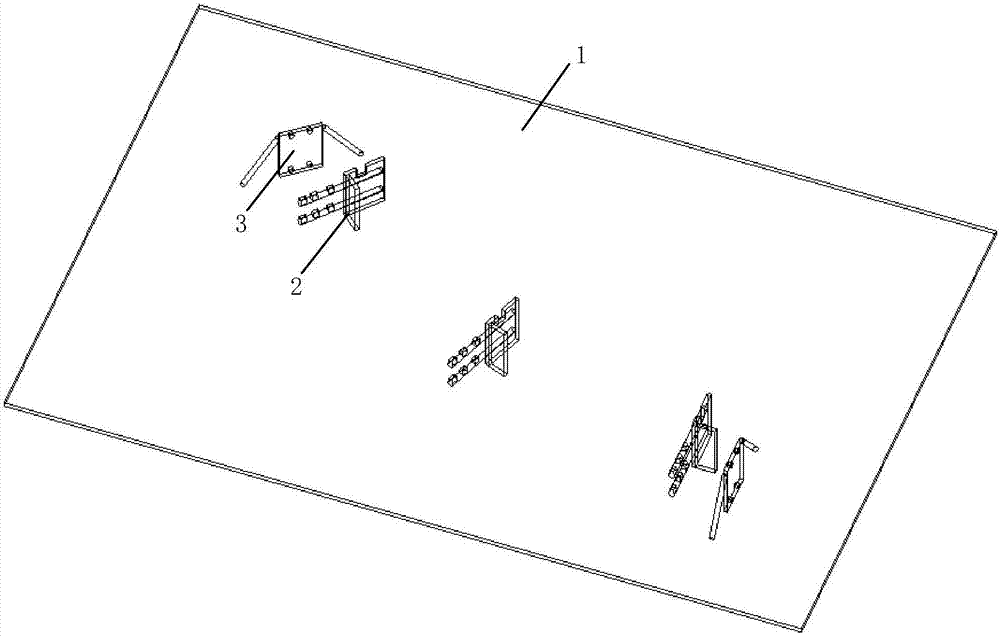

[0017] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

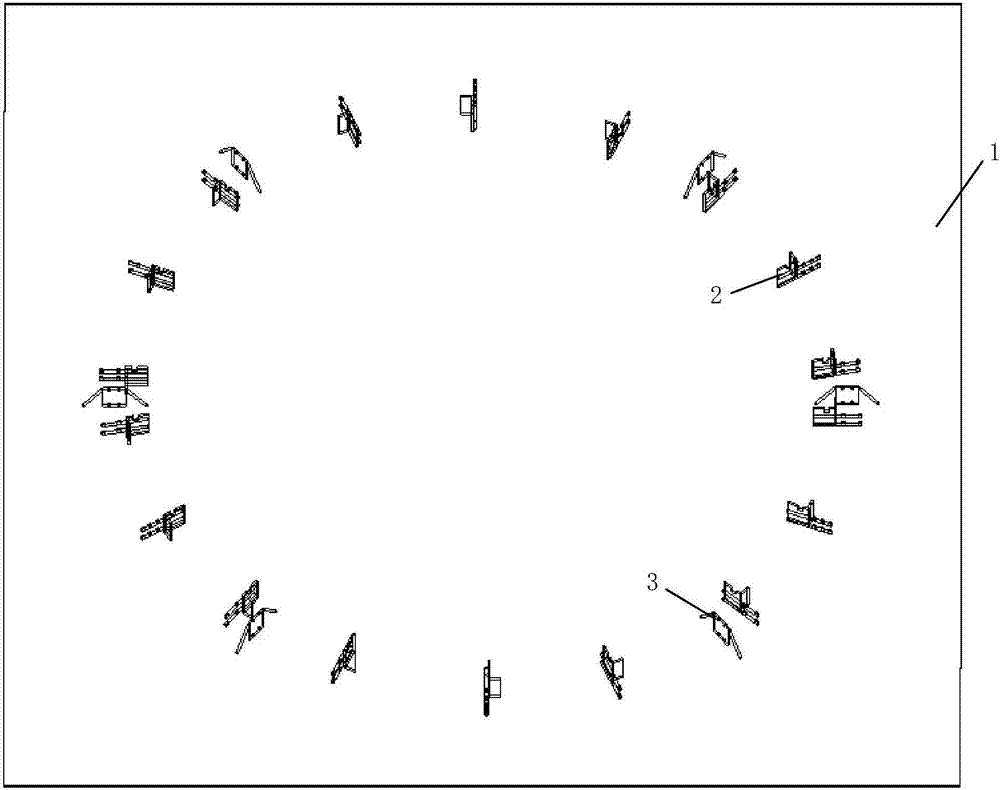

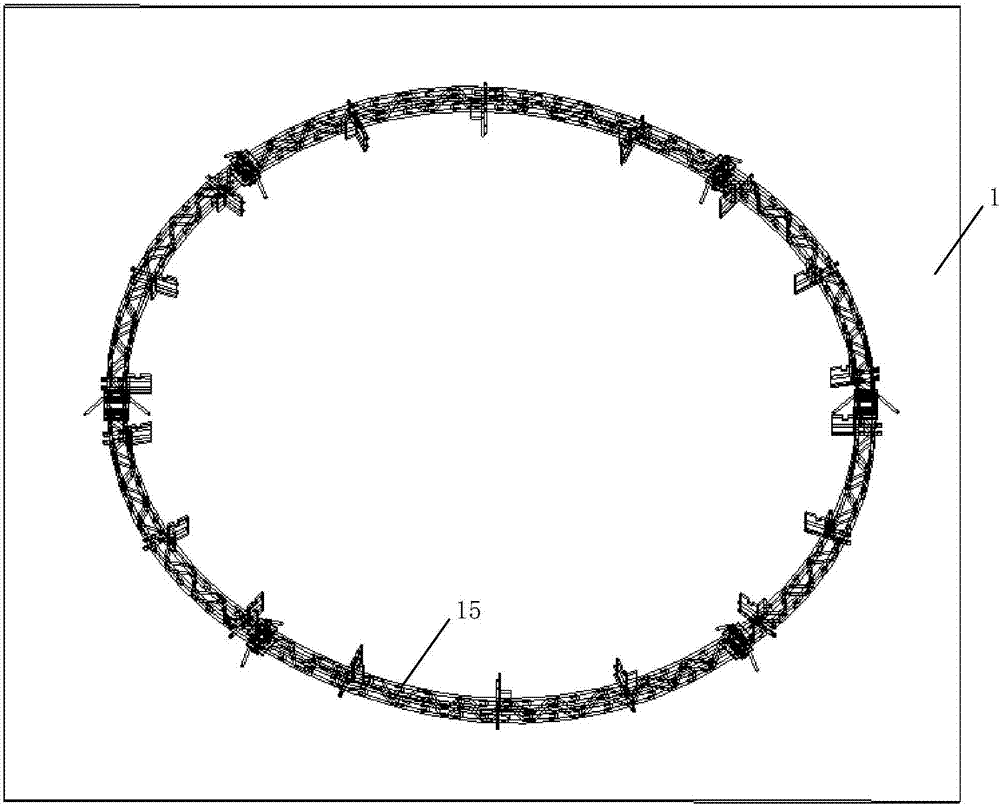

[0018] see Figure 1 to Figure 7 , a method of manufacturing a welding mold for the primary support grid steel frame of the mine method, the following steps are adopted:

[0019] 1) Design the grid steel frame welding mold according to the design drawing of the grid steel frame

[0020] The grid steel frame 15 is assembled and connected by a plurality of segments, and end plates are provided at both ends of the segments, and the end plates of two adjacent segments are connected together by bolts; Each section includes four grid steel frame main bars, which are divided into upper and lower layers, and each layer has two inner and outer bars. The four grid steel frame main bars are connected together through U-shaped structural bars and Z-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com