Inverted arch supporting assembly suitable for shield-type TBM tunnel prefabricated segmental lining structure

A technology for supporting components and supporting components, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of segment tunnel ovality exceeding the standard, tunnel segment leaking water, and inability to fill segment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

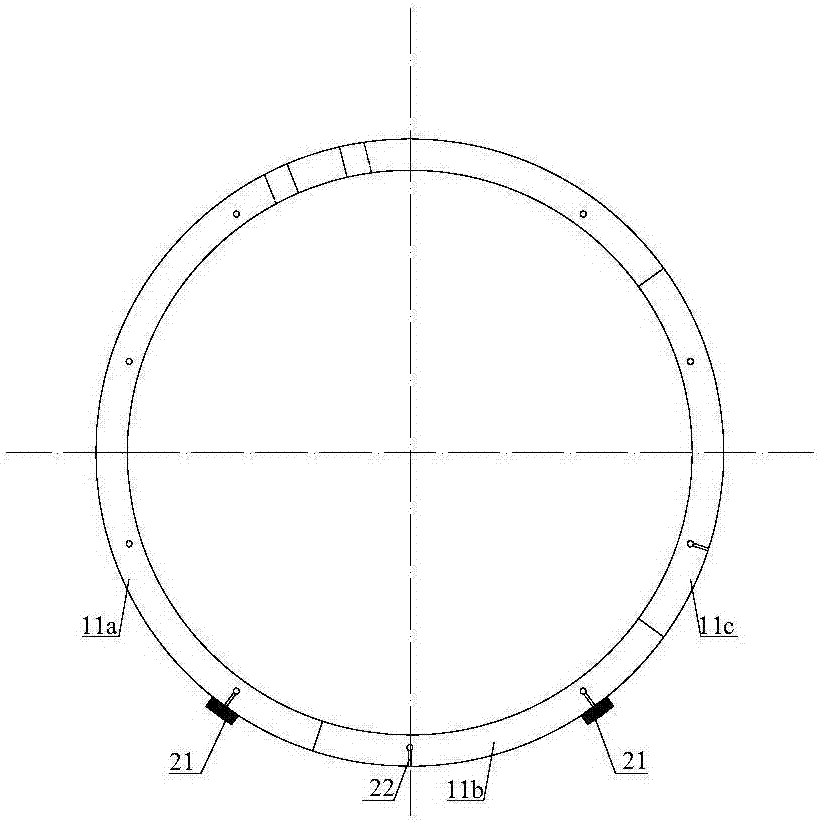

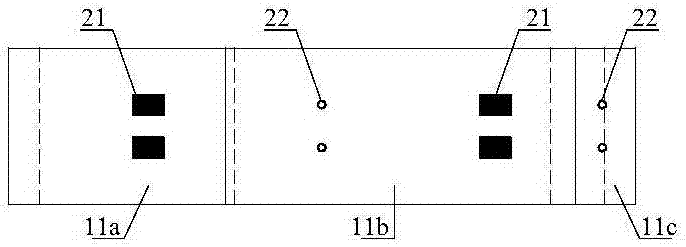

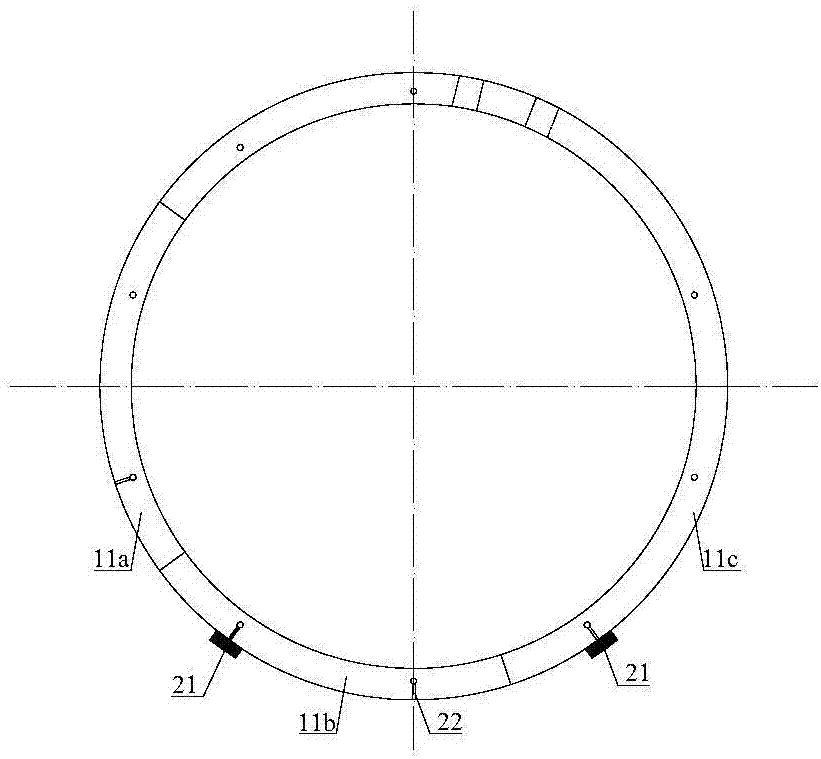

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 , an inverted arch support assembly suitable for the prefabricated segment lining structure of a shield-type TBM tunnel according to the present invention includes: a threaded sleeve 22 arranged inside the outer side of the prefabricated segment 11 according to the envelope of the assembly point; an inverted arch support member 21, It is arranged symmetrically on the outer side of the lower part of the inverted arch, and has an inverted arch support leg 21a and a support screw rod 21b. The support screw rod 21b and the threaded sleeve 22 form a detachable screw connection. as in figure 2 In the shown embodiment, prefabricated segment block one 11a, prefabricated segment block two 11b, and prefabricated segment block three 11c are provided with 4 rows and a total of 8 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com