A kind of method for chromium slag extraction chromic acid leaching pretreatment

A pretreatment and chromium slag technology, applied in the direction of improving process efficiency, etc., can solve the problems of unrecoverable trivalent chromium, difficulty in elution of chromium, and many impurities, and achieve the effect of reducing raw material consumption, reducing chromium content, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] This embodiment provides a method for chromium slag extracting chromium acid leaching pretreatment, the chromium slag is calcium-free roasted chromium slag, the main component and content are: Cr 2 o 3 9.84wt%, Al 2 o 3 18.63wt%, SiO 2 11.65wt%, Fe 2 o 3 37.53wt%, CaO2.04wt%, MgO19.71wt%, Na 2 O2.15wt%, here only expresses the component content by oxides, not the phase composition;

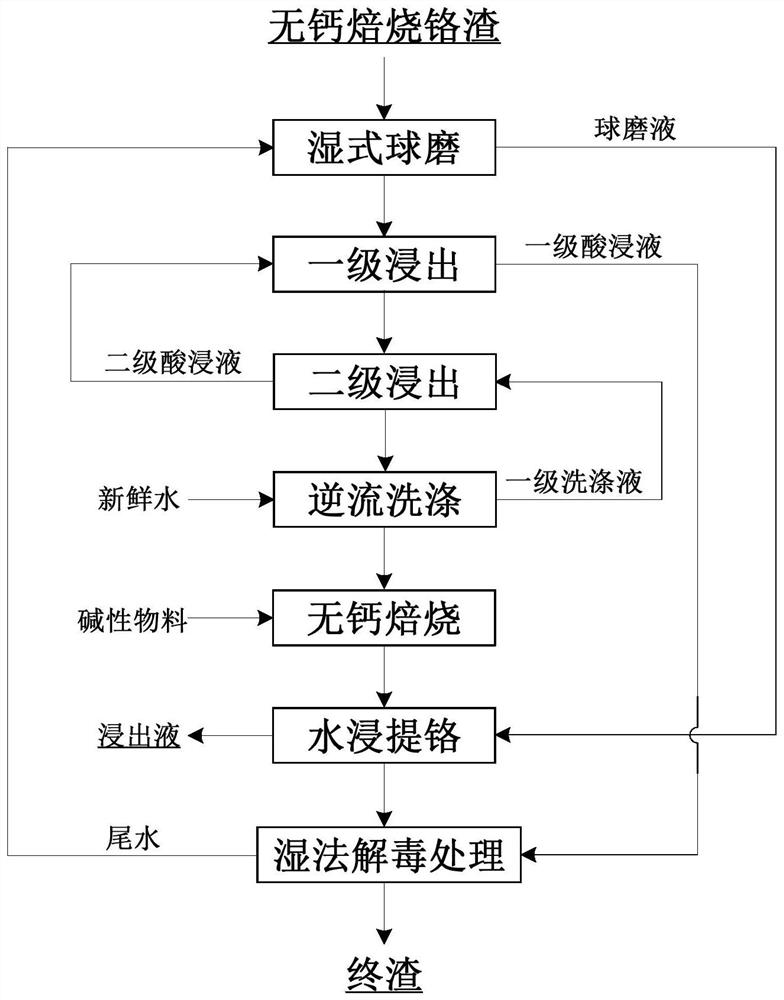

[0082] The process flow diagram of the method is as figure 1 shown, including the following steps:

[0083] (1) After the calcium-free roasted chromium slag is crushed, the liquid-solid ratio is 5m 3 : 1t carries out wet ball milling, filters and obtains ball milling slag and ball milling liquid, and the average particle size of described ball milling slag is 120 μ m, adds the sulfuric acid solution that concentration is 10wt% in ball milling slag and carries out one-stage leaching desiliconization, aluminum removal, one-stage leaching The liquid-solid ratio is 4m 3 : 1t, leaching...

Embodiment 2

[0089] This embodiment provides a pretreatment method for extracting chromium from chromium slag, the chromium slag is calcium-free roasted chromium slag, and its main components and contents are the same as in Example 1.

[0090] The method comprises the steps of:

[0091] (1) After the calcium-free roasted chromium slag is crushed, the liquid-solid ratio is 1m 3 : 1t carries out wet ball milling, filters and obtains ball milling slag and ball milling liquid, and the average particle size of described ball milling slag is 150 μ m, and adding concentration in ball milling slag is that the hydrochloric acid solution of 15wt% carries out primary leaching desiliconization, aluminum removal, primary leaching The liquid-solid ratio is 0.25m 3 : 1t, leaching temperature is 30 ℃, and leaching time is 120min, filters and obtains primary acid leaching solution and primary acid leaching residue, and the concentration of silicon in the primary acid leaching solution is 64.72g / L;

[009...

Embodiment 3

[0097] This embodiment provides a pretreatment method for extracting chromium from chromium slag, the chromium slag is calcium-free roasted chromium slag, and its main components and contents are the same as in Example 1.

[0098] The method comprises the steps of:

[0099] (1) After the calcium-free roasted chromium slag is crushed, the liquid-solid ratio is 2.5m 3 : 1t carries out wet ball milling, filters and obtains ball milling slag and ball milling liquid, and the average particle size of described ball milling slag is 100 μ m, and adding concentration to ball milling slag is that the sulfuric acid solution of 1wt% carries out one-stage leaching desiliconization, aluminum removal, one-stage leaching The liquid-solid ratio is 5m 3 : 1t, leaching temperature is 95 ℃, and leaching time is 25min, filters and obtains primary acid leaching solution and primary acid leaching residue, and the concentration of silicon in the primary acid leaching solution is 49.53g / L;

[0100] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com