Water separation industrialization method and device for vinylpyridine compound

A vinylpyridine and compound technology, applied in the field of vinylpyridine compound water separation industrialization methods and devices, can solve the problems of unsolved 2-vp, retention time to be maintained for more than half an hour, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

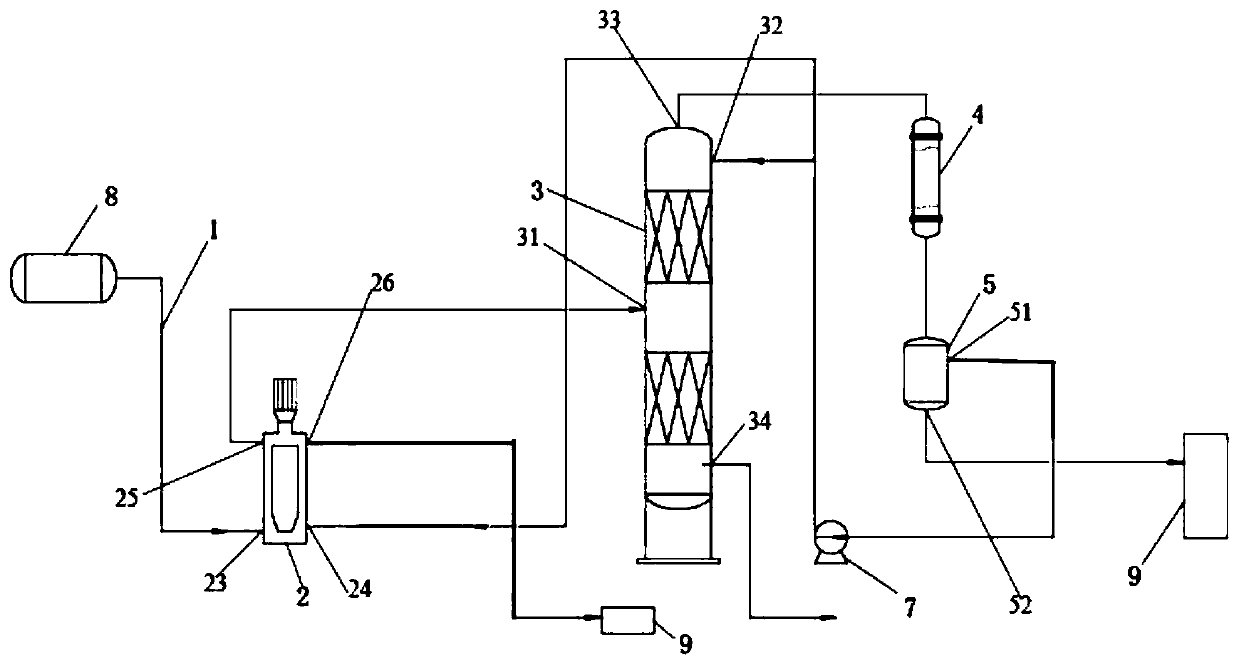

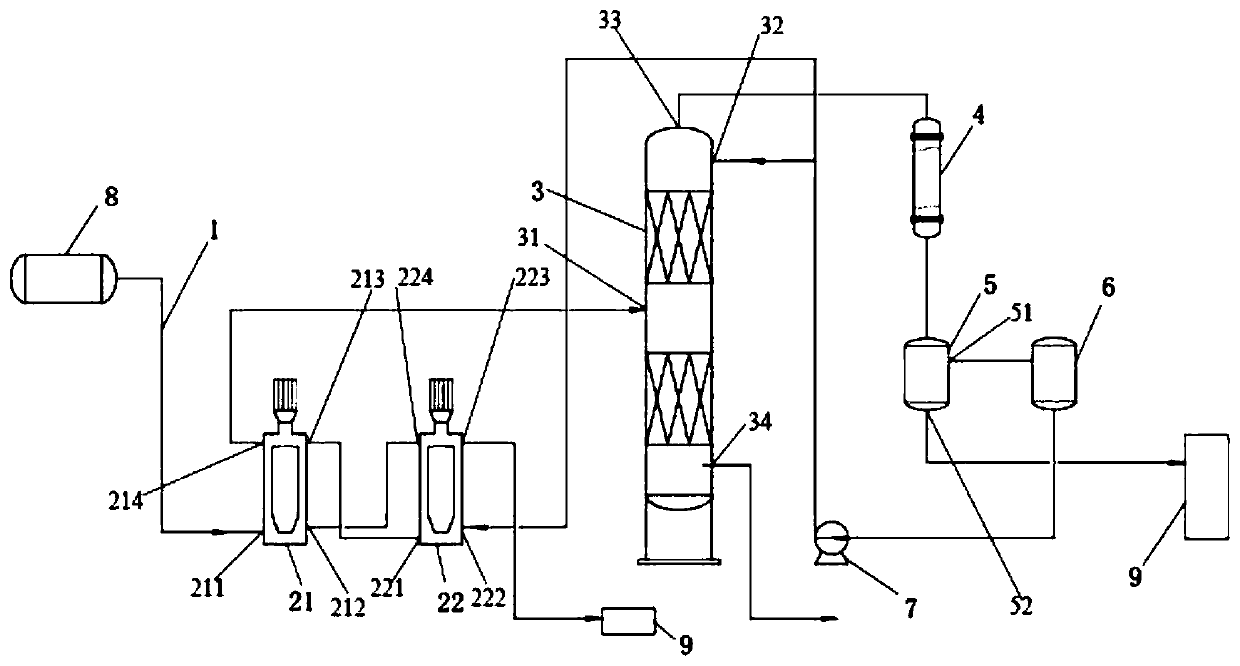

[0047] The vinylpyridine compound water separation industrial method provided in this example, the vinylpyridine compound in this example is 2-vinylpyridine, using such as figure 2 The shown water dividing device divides water, comprises the following steps:

[0048] S1 water separation process. Use toluene to carry out two-stage extraction in an extraction centrifuge on the undivided 2-vinylpyridine crude product, and centrifugal separation to obtain a mixed organic phase and water containing 2-vinylpyridine, extractant and trace water Phase; the volume ratio of the crude product of 2-vinylpyridine to the extractant is 1:0.6, and the centrifugal speed is 1500r / m;

[0049] S2 rectification process. Get the mixed organic phase that step S1 obtains and carry out rectification in rectification tower, rectification condition is: tower bottom temperature is 95 ℃, and pressure is-90kpa; Tower top temperature is 60 ℃, and pressure is 95kpa, Since the boiling point of the extractant...

Embodiment 2

[0052] The vinylpyridine compound water separation industrial method provided in this embodiment, the vinylpyridine compound in this embodiment is 4-vinylpyridine, using such as figure 2 The shown water dividing device divides water, comprises the following steps:

[0053] S1 water separation process. Use xylene to carry out two-stage extraction in an extraction centrifuge to the crude product of 4-vinylpyridine without water separation, and centrifuge to obtain a mixed organic phase containing 4-vinylpyridine, extractant and trace water and Aqueous phase; the volume ratio of the 4-vinylpyridine crude product to the extractant is 1:2, and the centrifugal speed is 1500r / m;

[0054] S2 rectification process. Get the mixed organic phase that step S1 obtains and carry out rectification in rectification tower, rectification condition is: tower bottom temperature is 95 ℃, and pressure is-90kpa; Tower top temperature is 60 ℃, and pressure is 95kpa, Since the boiling point of the ex...

experiment example

[0057] Use toluene and xylene as extractants to extract and centrifuge the crude product of 2-vinylpyridine (water content 25%). The amounts of toluene and xylene are shown in Table 1. Other steps are the same as in Example 1, and the existing The technical alkali analysis method and the heating method are compared, and the water content of the organic phase in the water separation process, the 2-vp content in the water phase, the 2-vp content of the tower top component in the rectification process, and the water content of the bottom component in the preparation process are compared. , and the product 2-vp yield was detected, and the results are shown in Table 1.

[0058] Table 1

[0059]

[0060]As can be seen from Table 1, adopt the method of the present invention, take toluene, xylene as extraction agent, when adding ratio (2-vp:A) (v / v) is 1:(0.25~0.75), after extracting and centrifuging, separate The 2-vp content (0~0.36%) in the wastewater is significantly lower tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com