Electronic hydraulic brake

A hydraulic brake, electronic technology, applied in the direction of brake, brake transmission, foot start device, etc., can solve the problems of inability to perform emergency braking, lack of booster vacuum source, lack of conditions, etc., to shorten the longitudinal direction. Layout space, shortening response time of pressure buildup, and reducing the effect of shell stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

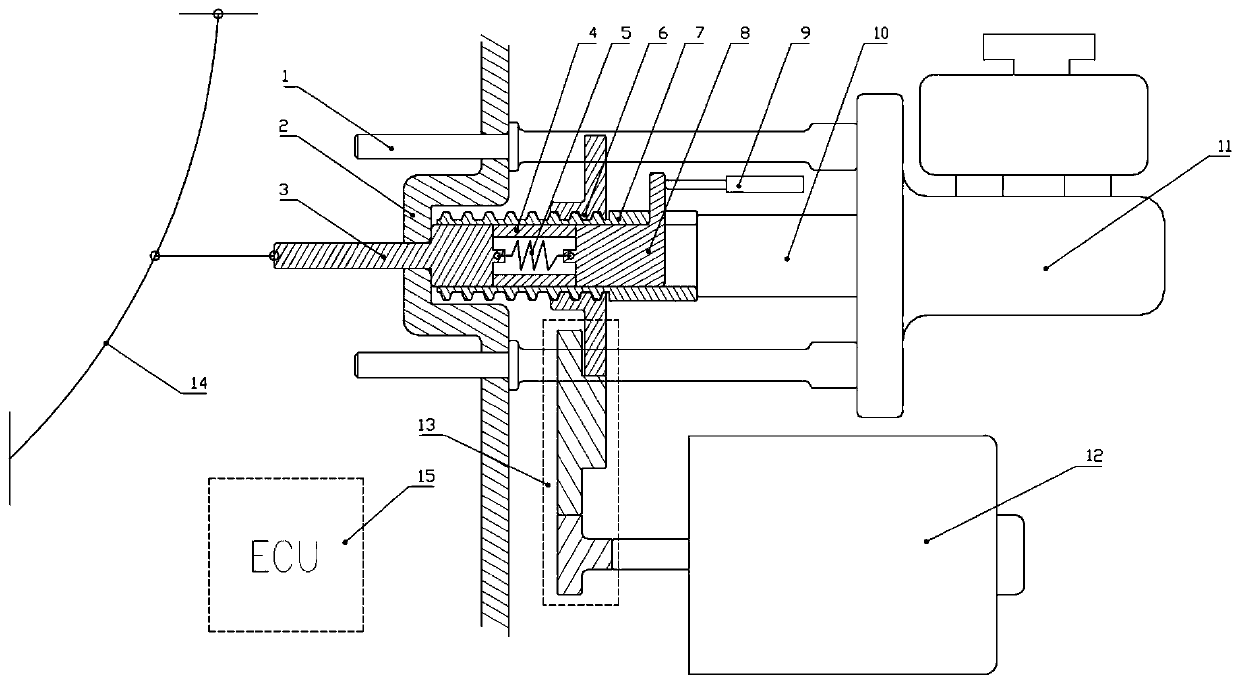

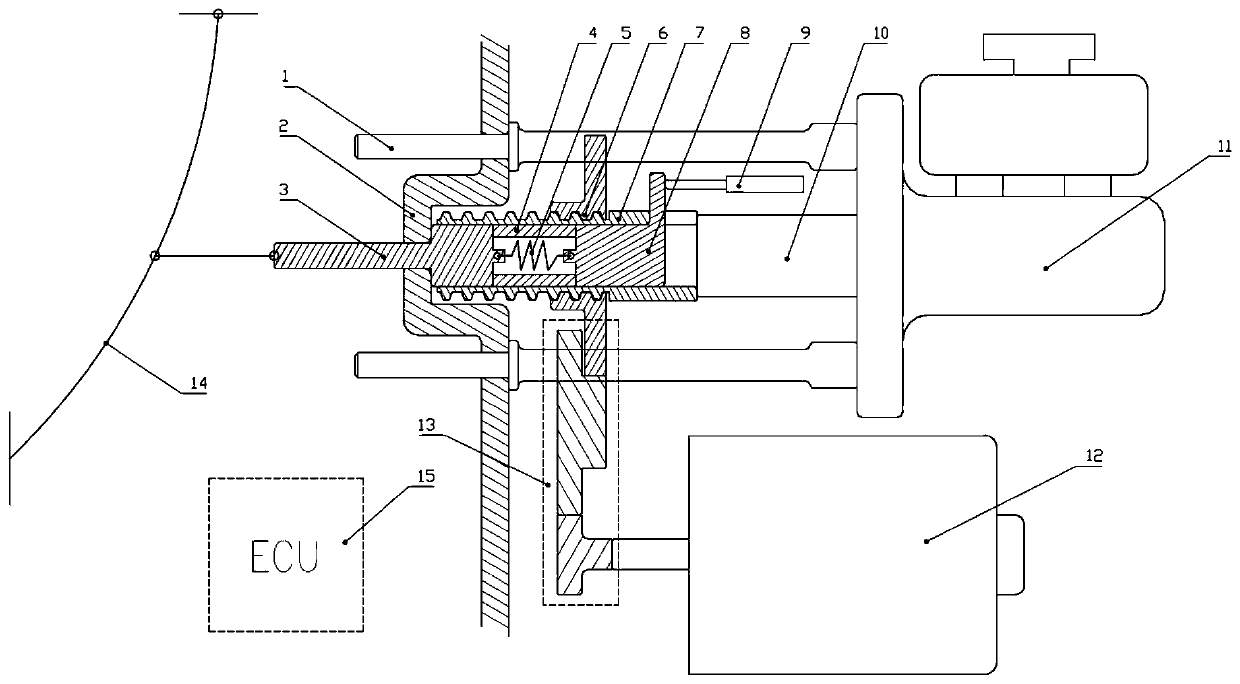

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The electronic hydraulic brake of the present invention includes a through rod 1, a housing 2, a push rod 3, a sleeve 4, an elastic element 5, a gear nut 6, a screw 7, a slider 8, a displacement sensor 9, a master cylinder piston 10, and a motor 12 , gear set 13, pedal 14 and ECU15, wherein one end of the through rod 1 passes through the housing 2 and is fixed at the installation position, and the other end is fixed with the master cylinder 11, and the through rod 1 can transmit the thrust of the master cylinder piston 10. One end of the push rod 3 is connected to the pedal 14 , and the other end is connected to the elastic element 5 . The push rod 3 is closely attached to the sleeve 4 . The sleeve 4 can slide in the screw rod 7 , one end is close to the push rod 3 , and the other end is close to the slider 8 , so as to transmit the thrust from the push rod 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com