An intelligent numerical control stepless control bending machine with improved structure

A bending machine, intelligent technology, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting efficiency, affecting the service life, increasing the cost of equipment use, etc., to improve the service life, effectively install and fix, and control the use. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

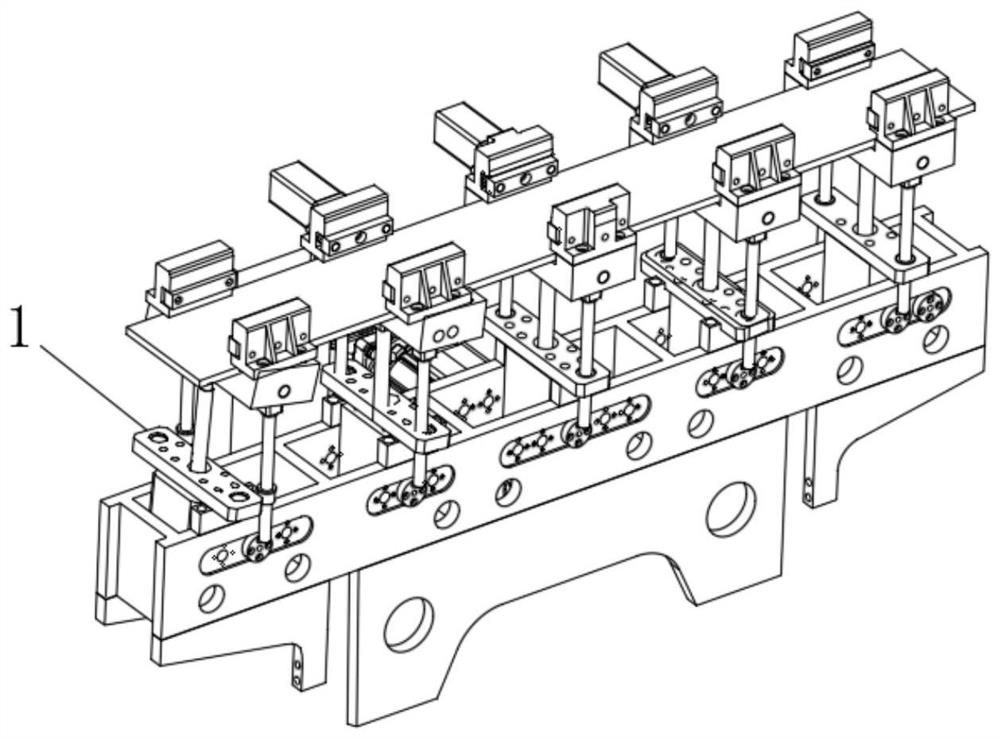

[0032] see Figure 3-5 , the present invention provides a technical solution: an intelligent digital control stepless control bending machine with an improved structure, including a pneumatic lifting base 1, which is the lower template installation structure inside the stepless control bending machine in the prior art , I won’t go into too much detail here;

[0033] The top of the pneumatic lifting base 1 is equidistantly equipped with a plurality of lower mold clamping mechanisms 2 that can be rolled and connected with the lower template, and both ends of the top of the pneumatic lifting base 1 are provided with end restraints that can be rolled and connected with the lower template. The position mechanism 3 is different from the prior art through the lower mold clamping mechanism 2 and the end limit mechanism 3 that can be rolled and connected with the lower formwork, and ensures that the lower formwork is effectively installed and fixed. During the processing, it can effec...

Embodiment 2

[0038] see Figure 6-7 , the present invention provides an optimized technical solution of Embodiment 1: the limit base 10 includes a fixed seat 13 and a cover plate 14, the fixed seat 13 is fixed at the end of the pneumatic lifting base 1, and the top of the fixed seat 13 The side close to the clamping mechanism 2 of the lower mold is provided with an insertion groove 15, the insertion groove 15 has a strip-shaped groove structure, and a plurality of the balls 12 are respectively provided with inner walls on both sides of the insertion groove 15, and the cover plate 14 is movable. Installed on the top of the fixing seat 13, and the cover plate 14 is also provided with a curved joint groove 7 communicating with the insertion groove 15. The insertion groove 15 and the curved joint groove 7 together form the insertion limit groove 11. When in use , after the lower template is fixed by the lower mold clamping mechanism 2, press its end into the insertion groove 15 in the fixing s...

Embodiment 3

[0041] see Figure 8-13 , the present invention provides an optimized technical solution of Embodiment 2: clips 17 are provided on both sides of the top of the fixing seat 13, and the fixing seat 13 is movably connected to the cover plate 14 through the clips 17, and the clips 17, while ensuring that the cover plate 14 and the fixing seat 13 are effectively fixed, it further facilitates the disassembly and fixing work of the cover plate 14 and the fixing seat 13, thereby further facilitating the fixing and limiting work of the end of the lower formwork .

[0042] The snap-in piece 17 includes a snap-in block 18, the snap-in block 18 is preferably a polygonal cylinder structure but not limited, the snap-in block 18 is fixed on the top of the fixing seat 13, and both sides of the cover plate 14 are provided with There is a through snap-in slot 19, the snap-in slot 19 is adapted to the structure of the snap-in block 18, and the snap-in block 18 is respectively fitted with the sn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com