A non-standard panel installation chassis and installation method thereof

An installation method and panel technology, which is applied in the direction of electrical components, electrical equipment shells/cabinets/drawers, etc., can solve the problems of only one or two panels, different sizes of panels, and inability to fix panels, etc. Achieve effective installation, avoid waste and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, for the installation of non-standard boards, it is only necessary to select a standard case slightly larger than the boards to be installed, instead of customizing the case. Slots are installed on the top and bottom beams simultaneously, the plug-in panel fixing holes 41 installed on the top are equal in size and distance to the plug-in panel fixing holes 41 installed on the bottom, and the plug-in guide rail fixing grooves 42 installed on the top are aligned with The dimensions and distances of the fixing grooves 42 of the plug-in guide rails installed at the bottom are equal. The fasteners are screws.

[0030] The installation method of the non-standard panel installation cabinet of this embodiment includes the following steps:

[0031] 1) According to the size of the board, choose a slightly larger standard chassis;

[0032] 2) The slots 5 are respectively fixed on the top and bottom beams 3 through the slot fixing holes, and the slots 5 are ins...

Embodiment 2

[0039] In this embodiment, for the installation of two non-standard boards with different sizes, a chassis not smaller than the larger board is selected. Only six pairs of slots are installed on both sides of the bottom, the size and spacing of the plug-in plate fixing holes 41 and the beam plate fixing holes 31 are the same, and the size and spacing of the plug-in guide rail fixing groove 42 and the beam guide rail fixing groove 32 are the same; Correspondingly inserted into the groove installed in the insert. The fasteners are screws.

[0040] The installation method of the non-standard panel installation cabinet of this embodiment includes the following steps:

[0041] 1) According to the size of the panel, select a chassis not smaller than the larger panel;

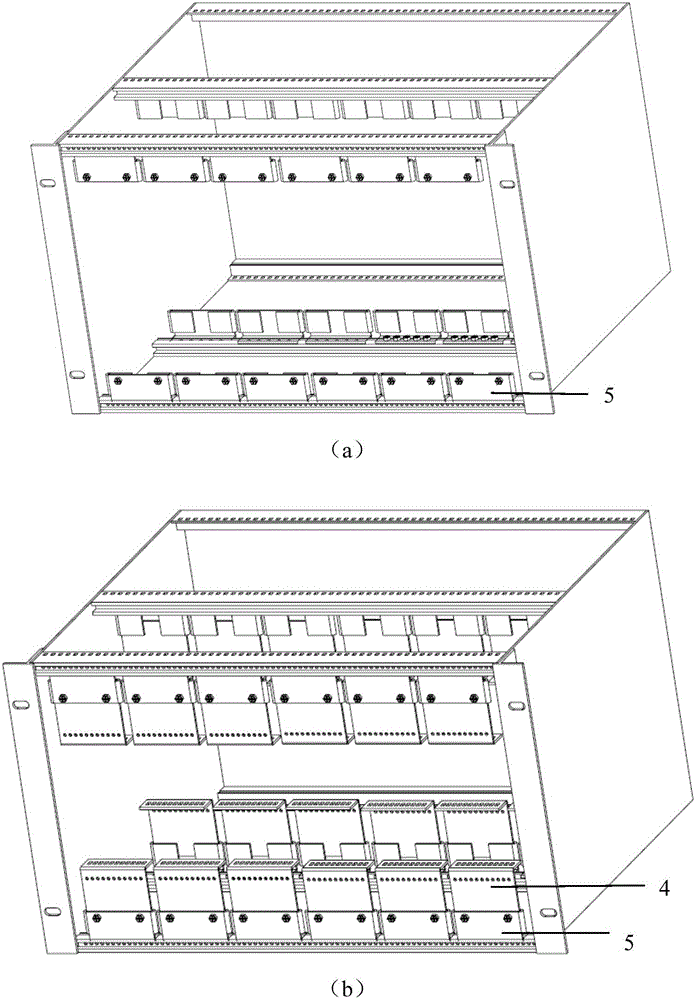

[0042] 2) Fix the slot 5 on the crossbeam 3 on both sides of the bottom through the slot fixing hole, such as Figure 4 as shown in (a);

[0043] 3) Correspondingly insert the plug-in 4 into the slot 5 installed at ...

Embodiment 3

[0048] In this example, there are three larger boards and three smaller boards installed in a standard case, choose a standard case with larger boards, and install six pairs of slots on both sides of the top and bottom , the plug-in plate fixing holes 41 and the plug-in guide rail fixing grooves 42 on the top are the same size and distance as the bottom plug-in board fixing holes 41 and the plug-in guide rail fixing grooves 42; Small non-standard boards are fixed with the plug-in board through the plug-in board fixing hole 41. The fasteners are screws.

[0049] The installation method of the non-standard panel installation cabinet of this embodiment includes the following steps:

[0050] 1) Select a standard chassis according to the larger board;

[0051] 2) Install the six guide rails on the top and bottom beam guide rail fixing grooves 32 respectively, then push the three larger standard boards 6 into the chassis along the guide rails, and fix the boards to the beam board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com