Preparation process of filter membrane of liquid medicine filter and the filter membrane of liquid medicine filter

A preparation process and filter technology, applied in the field of bacteria and virus filtration and particles, can solve the problems of easy adsorption of active ingredients of drugs, low material strength, long filtration path, etc., to meet the requirements of ultrafiltration filtration, high structural strength, Filter the effect of short paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a preparation process of a liquid medicine filter membrane and a medicine liquid filter membrane. Those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they all belong to the protection scope of the present invention. The process and application of the present invention have been described through preferred embodiments, and relevant personnel can obviously make changes or appropriate changes and combinations to the process and application herein without departing from the content, spirit and scope of the present invention to realize and apply the present invention Invent technology.

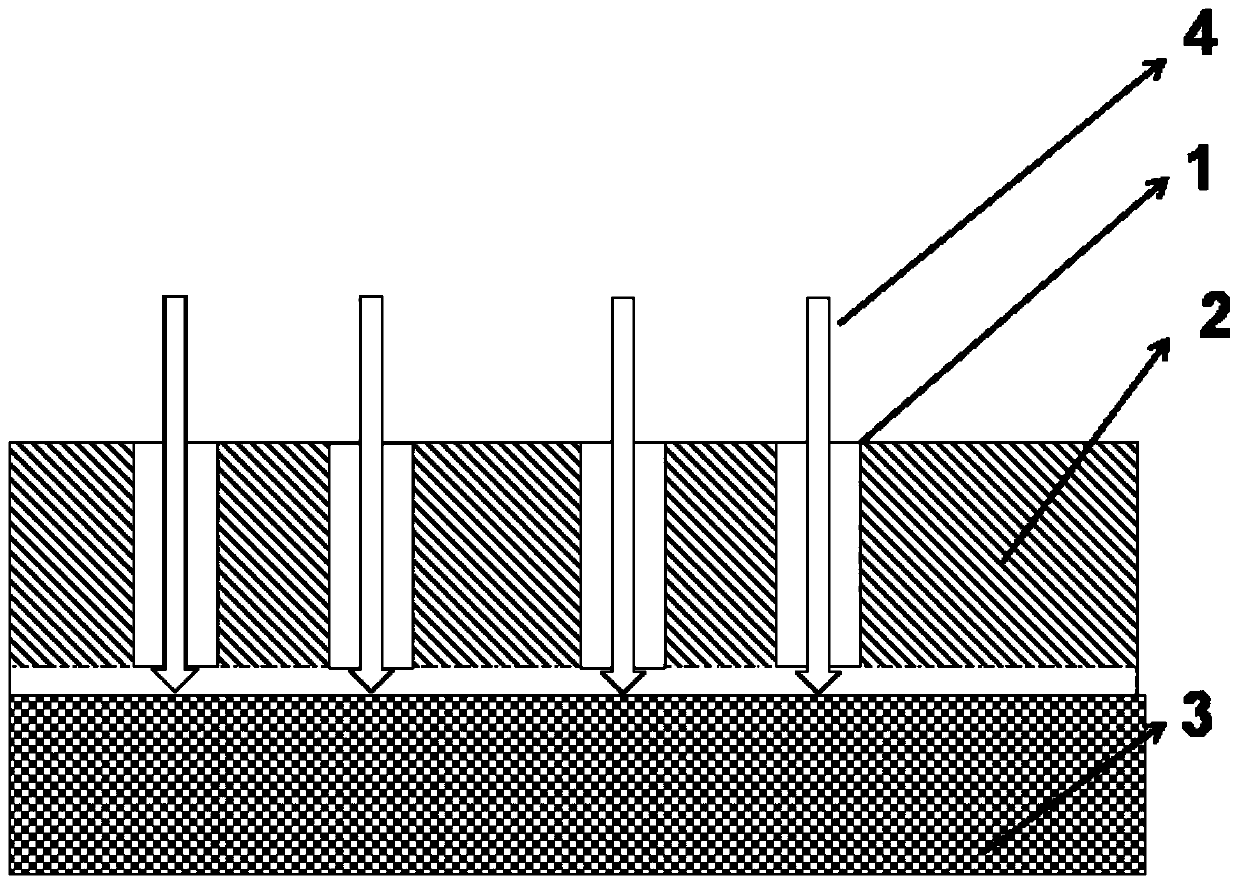

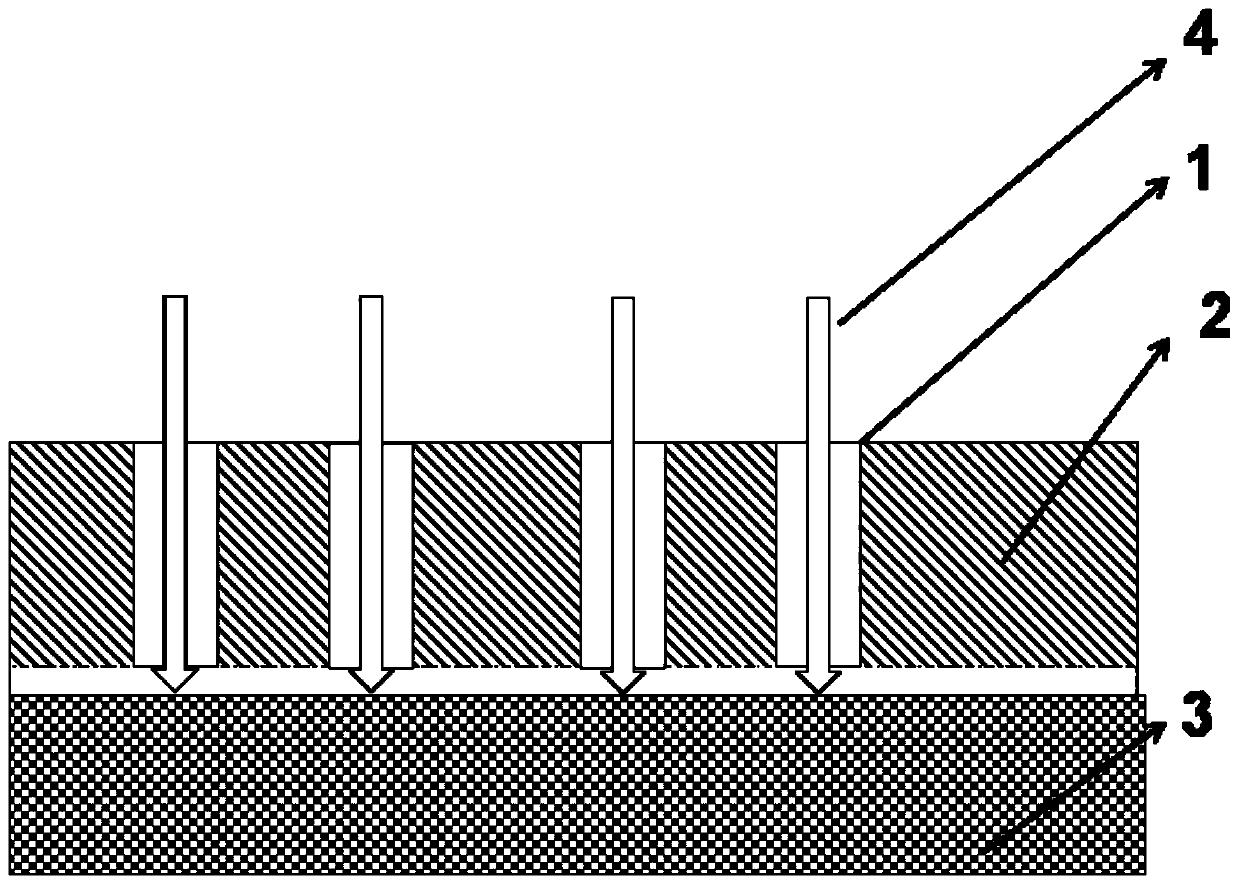

[0028] like figure 1 Shown, a kind of preparation technology of liquid medicine filter membrane, contains in the step of technology:

[0029] Select an ori...

Embodiment 1

[0044] like figure 1 As shown, taking the dual-channel AAO filter membrane as an example, one-sided etching was performed with a sodium hydroxide solution with a weight percentage of 5-10wt%, and the thickness of the filter membrane was finally reduced to 2 microns. Specifically include the following steps:

[0045] (1) The original filter membrane 2 (AAO) of porous anodic aluminum oxide with a pore size of 100 nanometers is selected, and the film thickness is more than 50 microns. The diameter is 25mm.

[0046] (2) Prepare the etching solution 3, that is, a sodium hydroxide solution with a weight percentage of 5-10 wt.%. The etching solution 3 is placed in a cylindrical container with an open top, and the hole diameter is 20 mm. The bottom of the container is connected with an inlet pipeline for injecting fresh etching solution.

[0047] (3) Hold the original filter membrane 2 to be thinned with plastic tweezers and place it at the top opening of the container. Simultaneo...

Embodiment 2

[0050] like figure 1 As shown, taking the dual-channel AAO filter membrane as an example, the phosphoric acid solution with a weight percentage of 5wt% was used for single-sided etching, and finally the thickness of the filter membrane was reduced to 500 nm. Include the following steps:

[0051] (1) The original filter membrane 2 (AAO) of porous anodic aluminum oxide with a pore diameter of 50 nanometers is selected, the film thickness is more than 50 microns, the filter hole 1 is a double channel, that is, it is connected to both sides of the front and back, and the original filter membrane 2 is overall external The diameter is 25mm.

[0052] (2) Prepare the etching solution 3, that is, a phosphoric acid solution with a weight percentage of 5wt%, and place the etching solution 3 in a container with an open top and a pore diameter of 20 mm. The bottom of the container is connected with an inlet pipeline for injecting fresh etching solution.

[0053] (3) Hold the original fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com