Immersed ultrafiltration membrane equipment with high integration level

A high-integration, ultrafiltration membrane technology, applied in ultrafiltration, membrane, membrane technology and other directions, can solve the problems of difficult maintenance, complex overall structure, large workload, etc., and achieve the effect of reducing construction accuracy requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

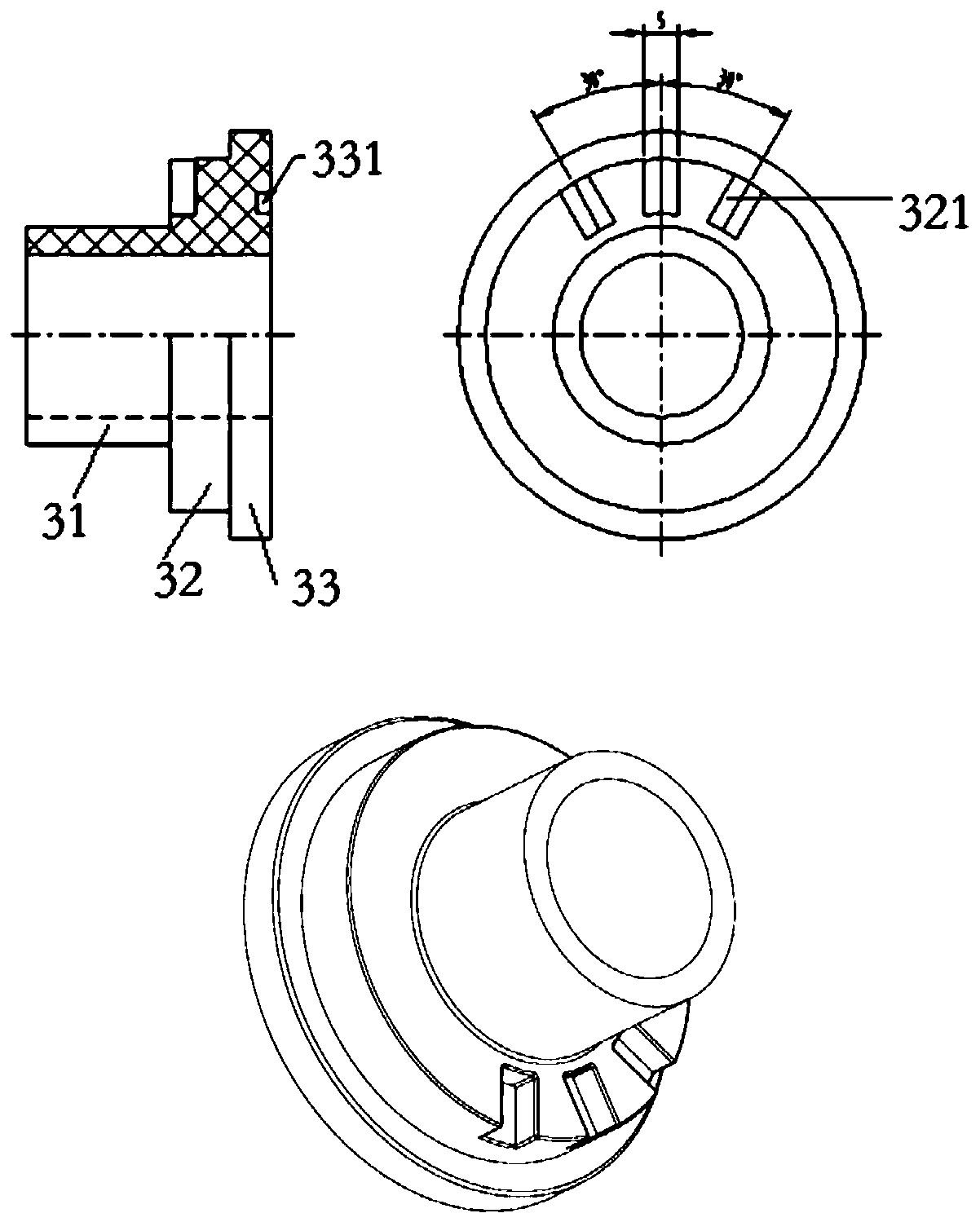

[0023] Figure 1-8 A highly integrated submerged ultrafiltration membrane device is shown, which is characterized in that it includes a plurality of ultrafiltration membrane assemblies arranged symmetrically in two rows of brackets 7; the ultrafiltration membrane assembly includes a housing 8 and is arranged on the The membrane tow bundle in the shell; one end of the membrane tow bundle is a water-producing end, and the other end is a closed end; the water-producing end is provided with a water-producing box 81, and the closed end is provided with an aeration box 82; the water production box is provided with a fixing resin to fix the film tow; the top of the water production box is provided with a water production port t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com