Discharge plate structure and air purifier single high-voltage electric field module

An air purifier and high-voltage electric field technology, which is applied in the field of air purification, can solve the problems of large mass of electric field modules, short cleaning cycle intervals, frequent cleaning, etc., and achieve the effects of low production difficulty, low production cost, and reduced material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

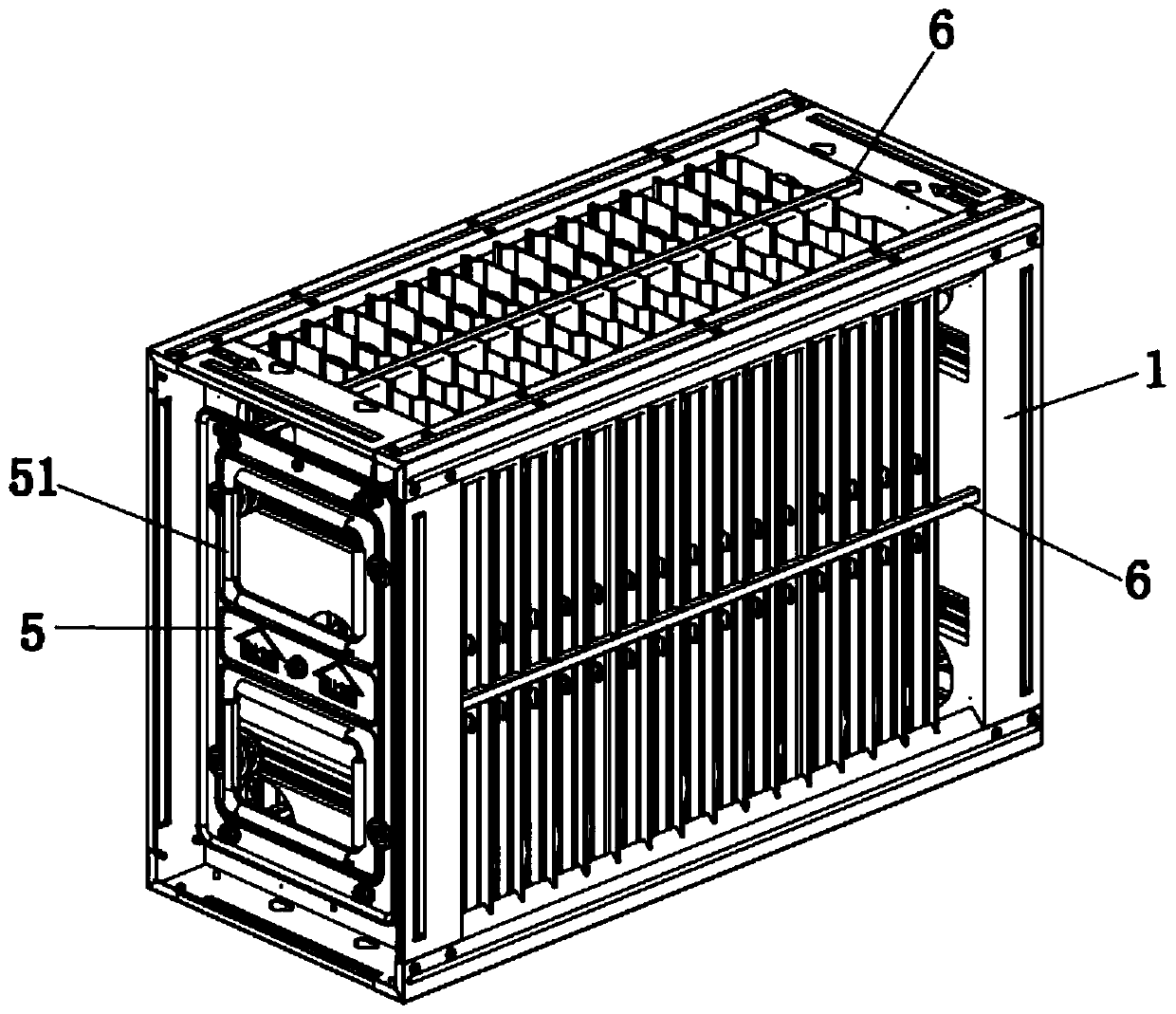

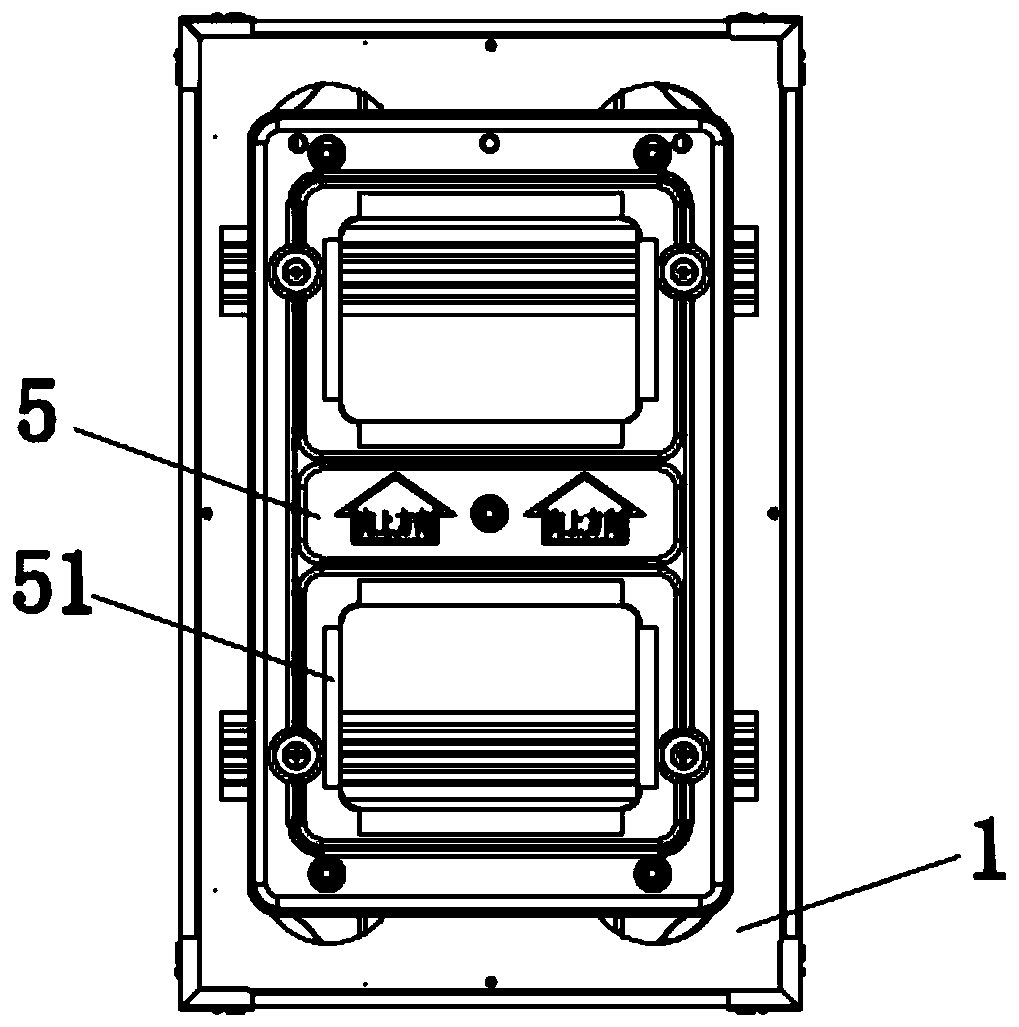

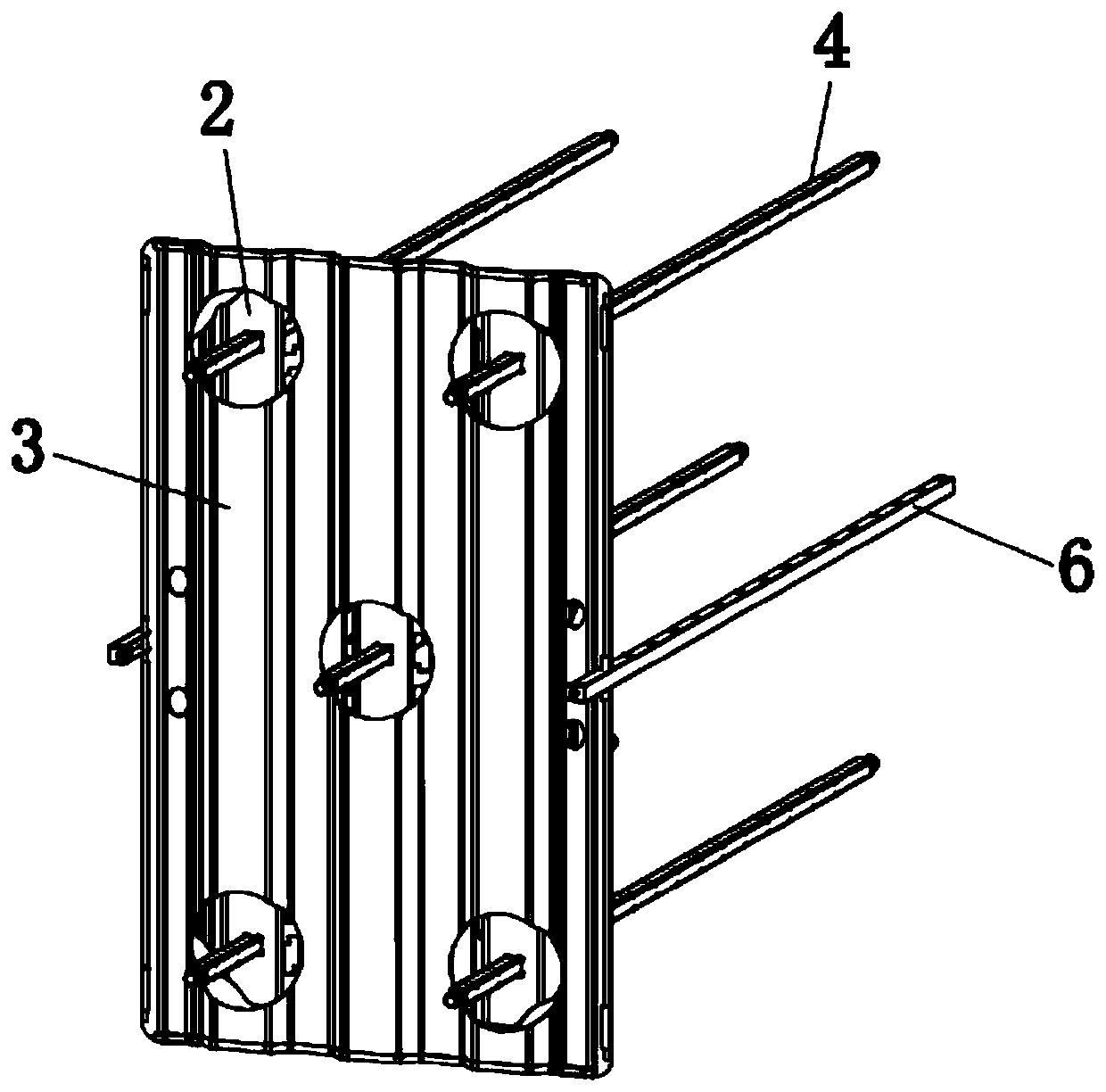

[0035] The specific embodiment of the present invention is as Figure 1 to Figure 7 As shown, among them, Figure 6 It is a discharge plate structure, including a discharge plate 2 and several discharge teeth 7, and the discharge plate 2 includes at least one discharge plate bending portion 22 and at least one discharge plate surface 21 connected along the wind inlet direction. The discharge teeth 7 are arranged on the bending portion 22 of the discharge plate. The bending part 22 of the discharge plate includes at least one bending place, and the bending place is in the shape of a corner or an arc. In this embodiment, the bending part of the bending part 22 is in the shape of a corner.

[0036] A through hole 8 is provided on the bending portion 22 of the discharge plate, and at least two discharge teeth 7 with opposite ends are provided at the inner edge of the through hole 8 . In this embodiment, two discharge teeth 7 with opposite ends are provided at the inner edge of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com