Automatic retractable film punching machine

A technology of automatic retractable and film processing machines, which is applied in the fields of final product manufacturing, electrochemical generators, primary batteries, etc., can solve the problems of film processing troubles, low production efficiency, and large labor consumption, and improve the quality of film processing, Good punching effect, saving power source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will now be further described with reference to specific embodiments. The following embodiments are intended to illustrate the present invention rather than further limit the present invention.

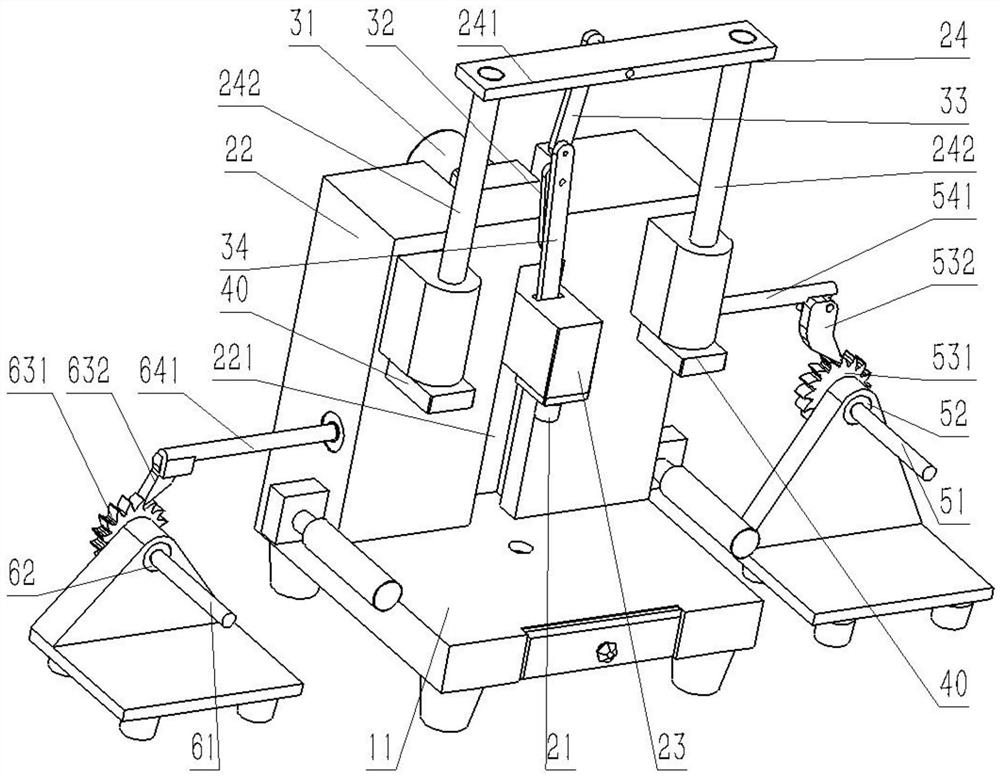

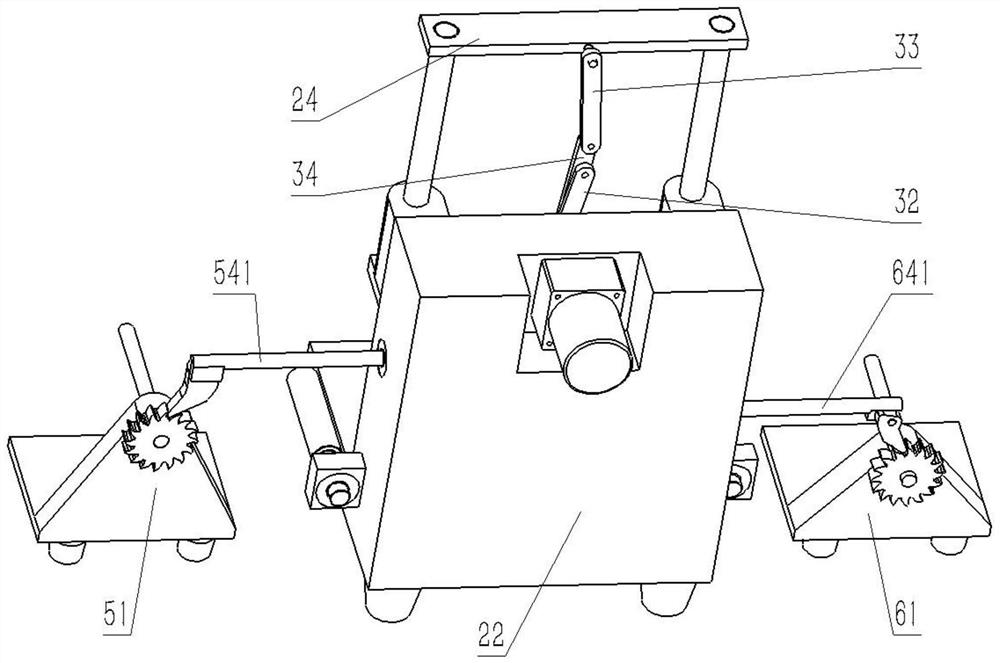

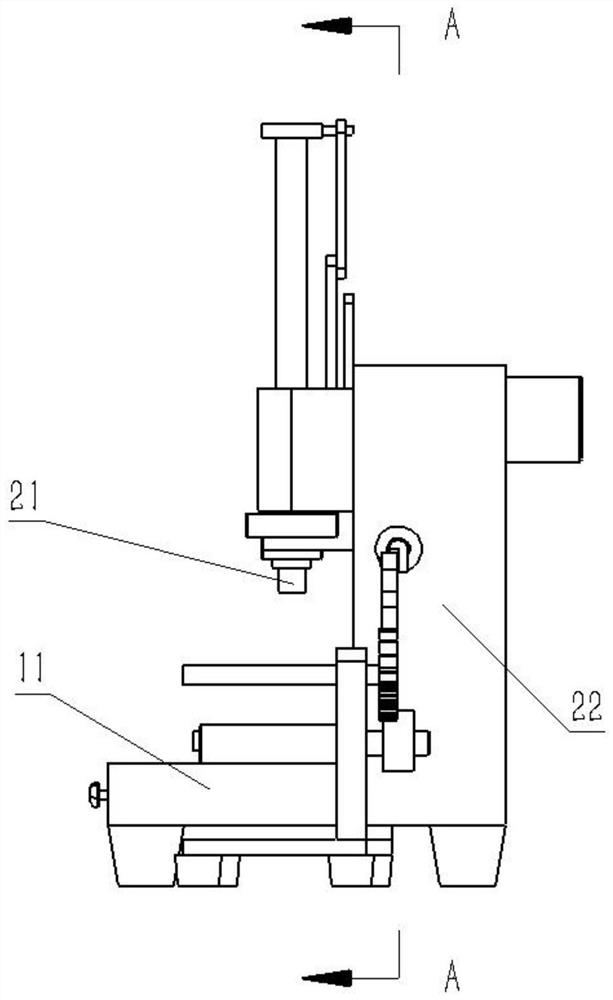

[0032] combine Figure 1-6, the present invention provides a new type of automatic rewinding and unwinding tablet punching machine, which includes a frame, a punching base 11 and a punching mechanism fixed on the frame, and also includes a feeding mechanism and a flattening mechanism linked with the punching mechanism. The punching mechanism includes a punch 21, a punch vertical lifting guide assembly and a link-type punching drive assembly, and the punch vertical lifting guide assembly includes a punching fixed seat 22, which is vertical to the punching fixed seat 22. The T-shaped slider 23 is slidably connected and the lifting frame 24 is slidably connected with the punching piece fixing seat 22. The punch 21 is fixed on the bottom of the T-shaped slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com