Speed-change and transposition scraping device

A technology of indexing and cutting, used in lamination auxiliary operations, chemical instruments and methods, metal processing, etc., can solve problems such as high cost and large volume, and achieve the effect of extending service life and reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

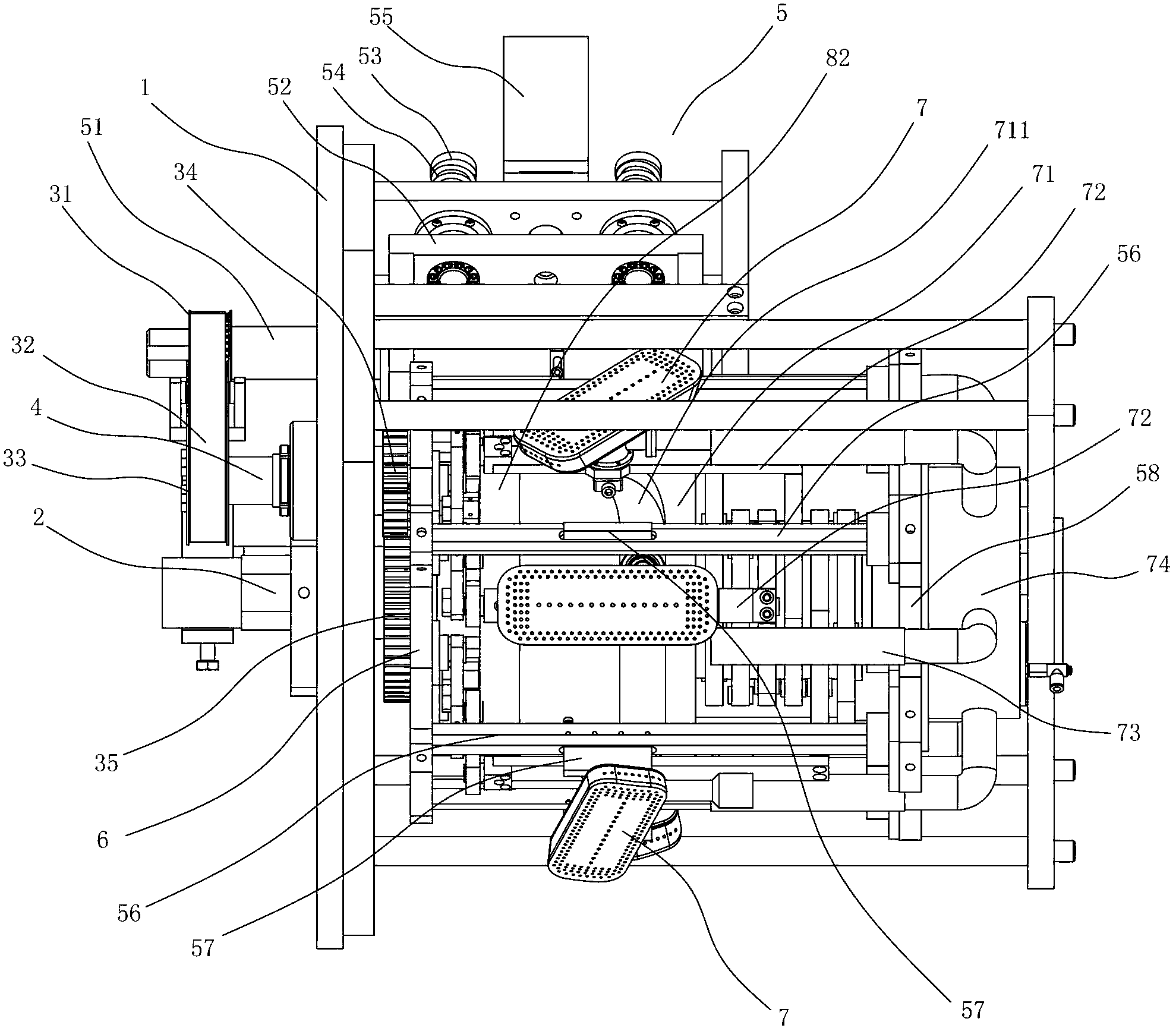

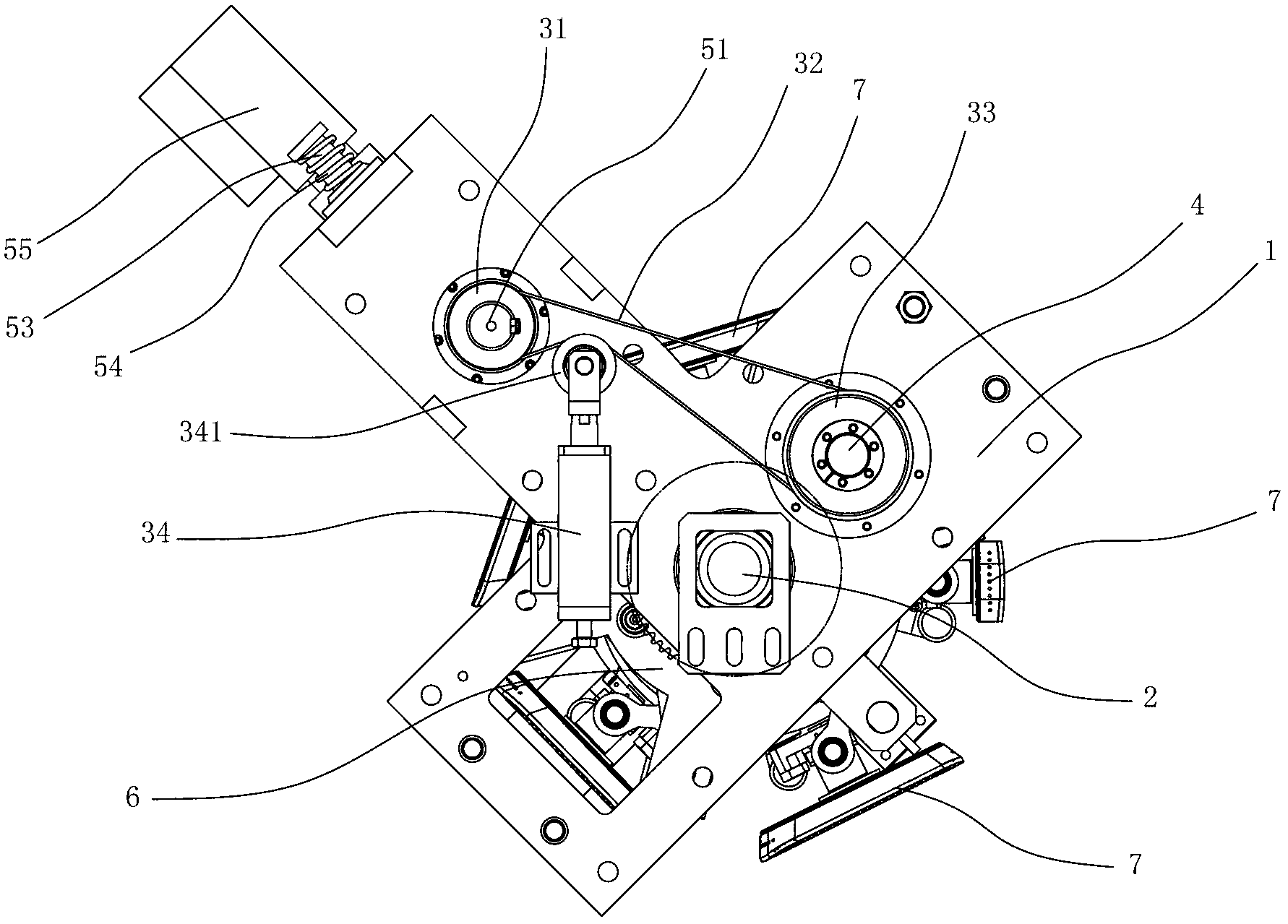

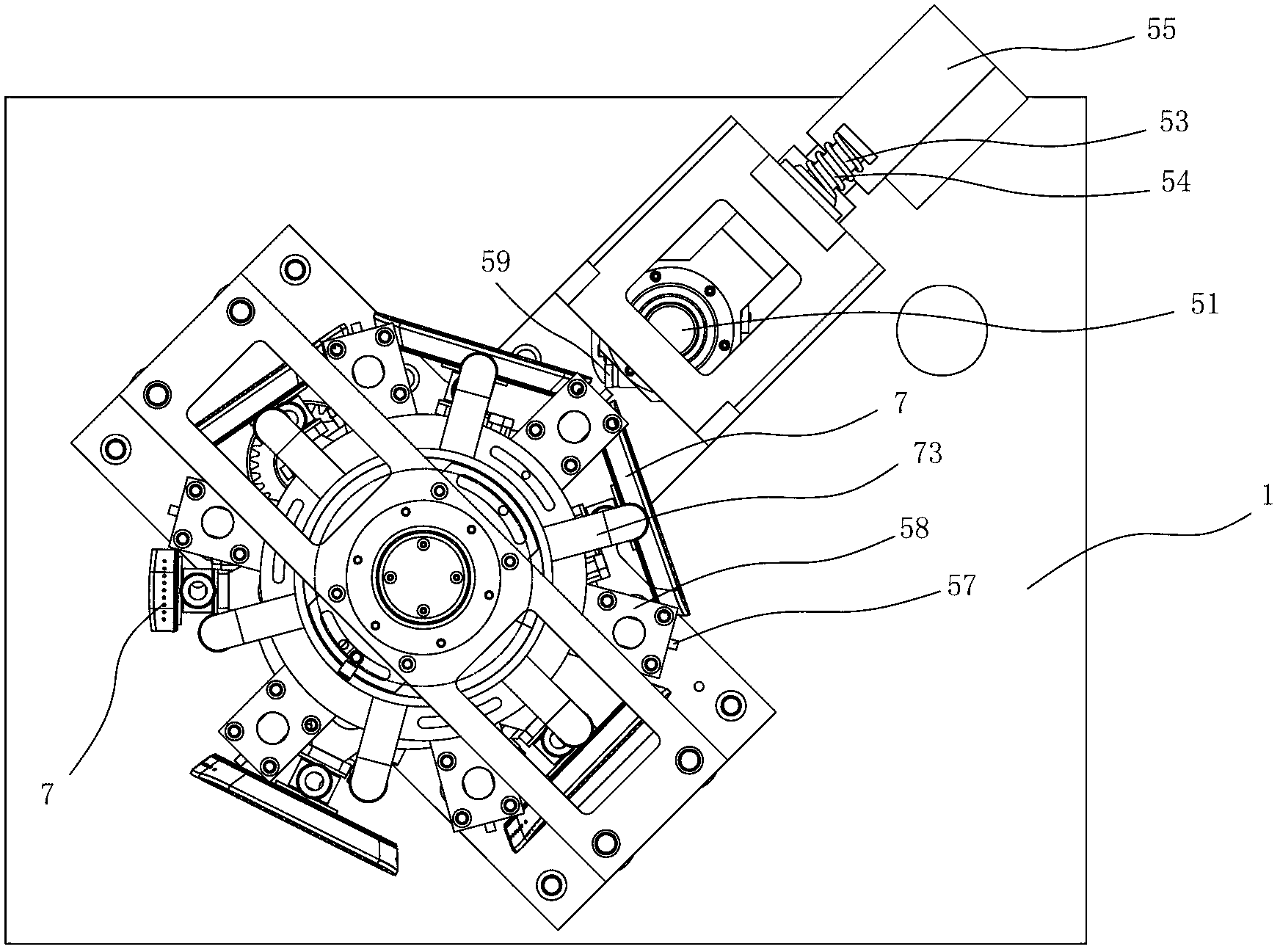

[0025] refer to Figure 1 to Figure 6 As shown, a variable-speed indexing and scraping device is used to convey continuous flexible materials at variable speeds and to cut and index flexible materials during transportation, including a frame 1 and a support shaft 2 fixed on the frame 1 , the eccentric sleeve 9 that is eccentrically arranged on the support shaft 2, the space cylindrical cam 71 with a track groove 711 formed on the outer peripheral surface of the eccentric sleeve 9 through the expansion sleeve 76, and the space cylindrical cam 71 that is rotatably arranged on the eccentric sleeve 9 through the bearing 721 and the circumference The distribution of six revolving frames 72, the negative pressure adsorption block 7 that is rotatably arranged on each revolving frame 72 through the pivot shaft 74 extending radially along the space cylindrical cam, is arranged on the track of the pivot shaft 74 and the space cylindrical cam 71 Between the grooves 711, the swing rod 75 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com