Battery module foam type selection method and battery module

A battery module and foam technology, which is applied to battery pack parts, secondary batteries, circuits, etc., can solve the problems of battery pre-tightening force, cell expansion space, etc., to ensure reliable structure and reduce foam selection process , to ensure the effect of the module structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

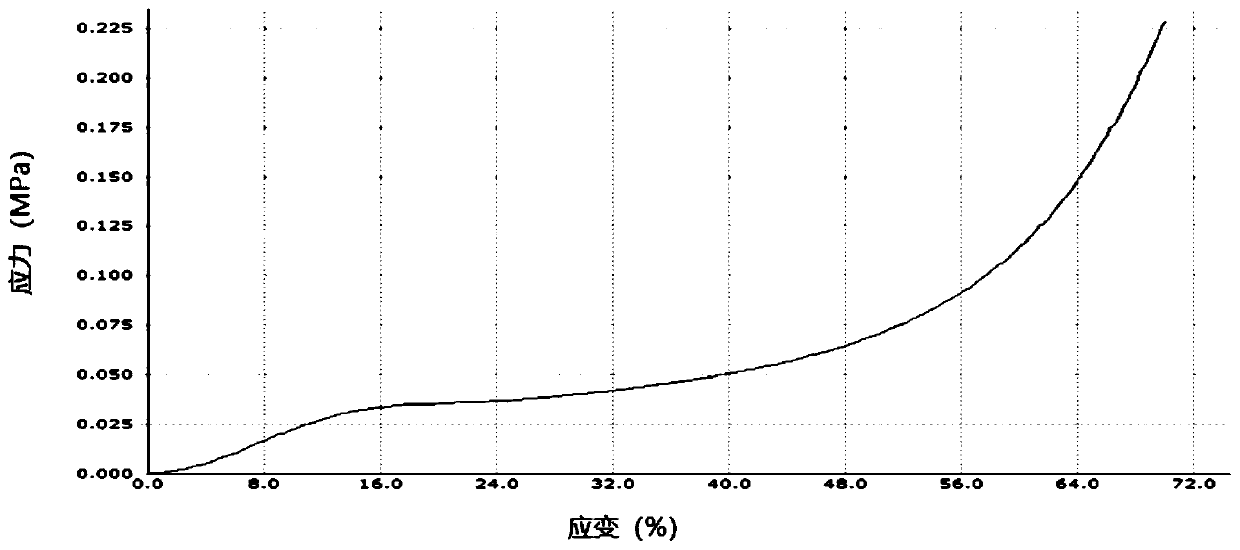

[0065] The present embodiment carries out foam selection according to the following method:

[0066] This embodiment uses VDA355 module, module size: 355×151×108.5mm, battery size: 310×102×11mm; module width: 151mm, thickness of all batteries: 11×12=132mm, other zeros The sum of the thickness of the parts (insulation board and glue): 9mm.

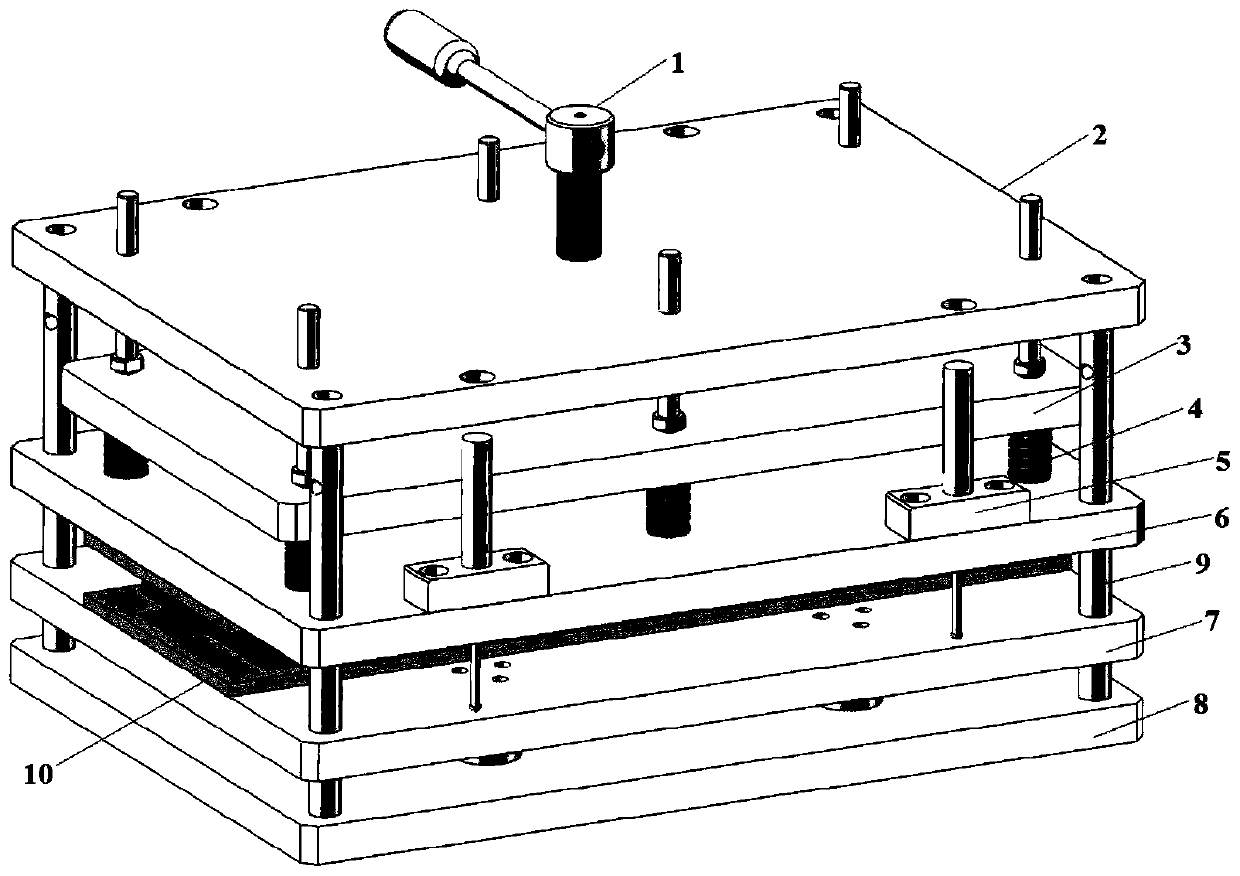

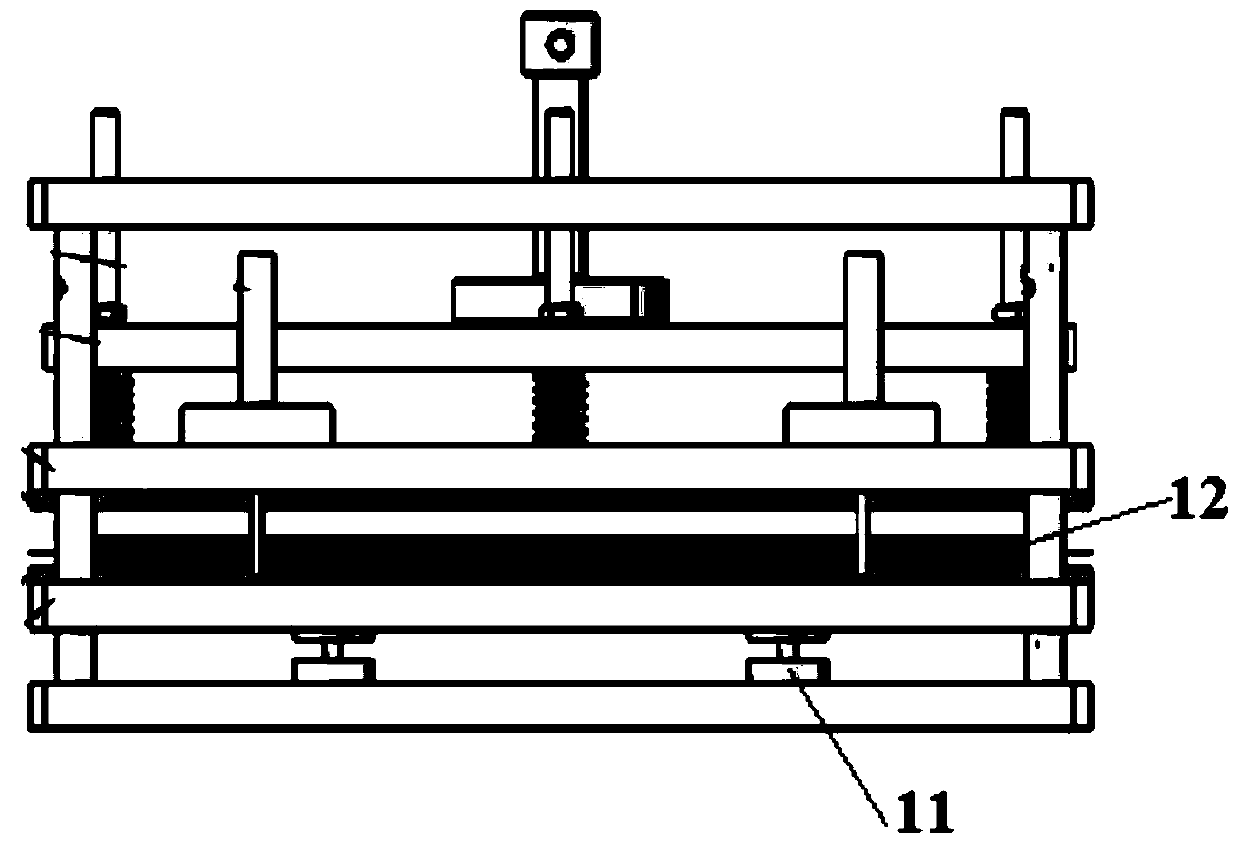

[0067] (1) use figure 1 and figure 2 The battery cell detection device shown tests the cell preload F and the cell expansion space φ. The best pre-tightening force F of the measured cell is 30KPa and the expansion space of the cell is 5% for φ.

[0068] The battery cell detection device includes a screw 1, a pressure plate 3, an elastic component 4, an upper splint 6, a lower splint 7, and a pressure sensor 11 from top to bottom, and a displacement sensor 5 is provided on the edge of the upper splint 6; The bottom of the screw 1 is in contact with the pressure plate 3, and is arranged in the middle of the pressure plate 3. There are at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com