Preparation method of film for regulating and controlling electrocaloric performance through substrate

A technology of substrate and thin film is applied in the field of preparation of thin films for regulating electric card performance through substrates, and achieves the effects of high purity, convenient and quick preparation technology, and high electric field breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

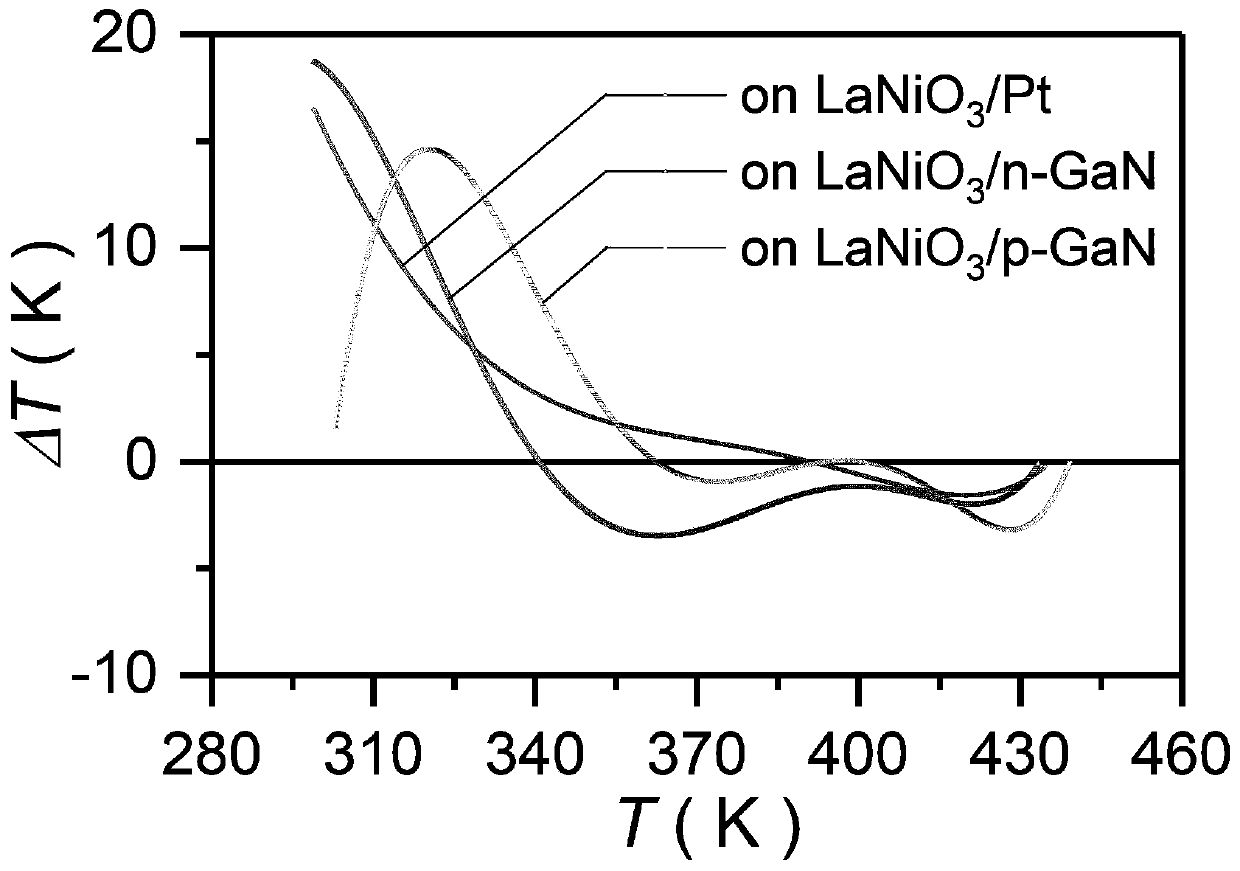

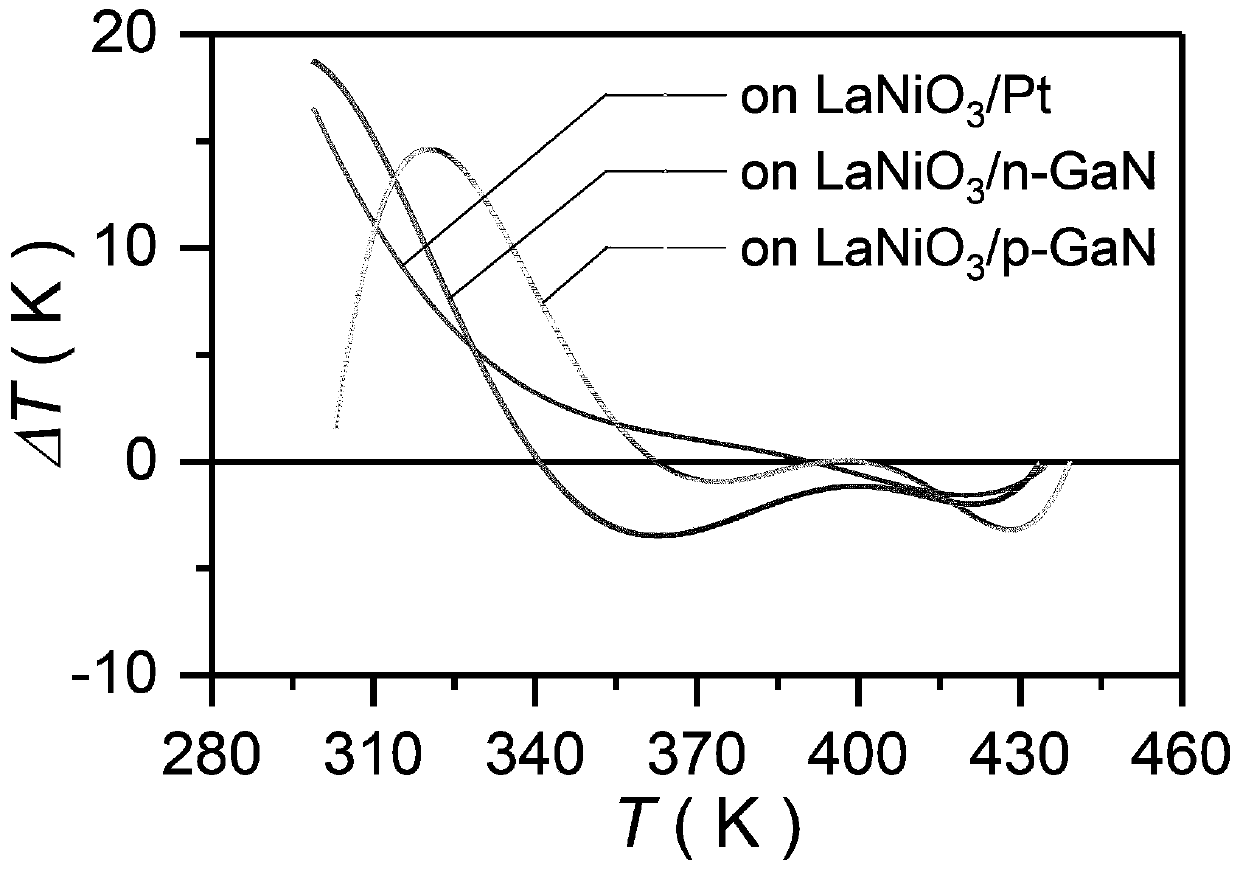

Image

Examples

Embodiment 1

[0026] (1) The raw material Ni(CH 3 COO) 2 , La(NO 3 ) 3 Dissolve in a mixed solution of glacial acetic acid, water and formamide at room temperature, and then place the solution for 20 hours to obtain LaNiO with a concentration of 0.3M. 3 Precursor solution

[0027] (2) The LaNiO obtained in step (1) 3 The precursor solution was spin-coated on Pt(111) / TiO using a homogenizer at 4000rpm for 30s x / SiO 2 / Si(100) substrate to obtain the first wet film;

[0028] (3) The first wet film prepared in step (2) was first dried at 180°C for 3 minutes, then pyrolyzed at 450°C for 10 minutes, and finally annealed at 700°C in air atmosphere for 5 minutes. Get a layer of LaNiO 3 film;

[0029] (4) Repeat step (2) and step (3) 6 times to obtain LaNiO with 6 layers 3 LaNiO 3 / Pt(111) / TiO x / SiO 2 / Si(100) composite substrate;

[0030] (5) Pb(CH 3 COO) 3 , Ba(CH 3 COO) 2 And C 6 H 9 O 6 La·xH 2 O was dissolved in the first mixed liquid of glacial acetic acid and deionized water at 120℃, and then Zr(O...

Embodiment 2

[0035] (1) The raw material Ni(CH 3 COO) 2 , La(NO 3 ) 3 Dissolve in a mixed solution of glacial acetic acid, water and formamide at room temperature, and then let the solution stand for 25h, and finally get LaNiO with a concentration of 0.3M 3 Precursor solution

[0036] (2) The LaNiO obtained in step (1) 3 The precursor solution was spin-coated on the n-type GaN substrate using a homogenizer at 5000 rpm for 40 seconds to obtain the first wet film;

[0037] (3) The first wet film produced in step (2) was first dried at 200°C for 4 minutes, then pyrolyzed at 500°C for 12 minutes, and finally annealed at 750°C in air atmosphere for 8 minutes. Get a layer of LaNiO 3 film;

[0038] (4) Repeat step (2) and step (3) 6 times to obtain LaNiO with 6 layers 3 LaNiO 3 / n-type GaN composite substrate;

[0039] (5) Pb(CH 3 COO) 3 , Ba(CH 3 COO) 2 And C 6 H 9 O 6 La·xH 2 O was dissolved in the first mixed liquid of glacial acetic acid and deionized water at 120℃, and then Zr(OC 3 H 7 ) 4 Dissolve ...

Embodiment 3

[0044] (1) The raw material Ni(CH 3 COO) 2 , La(NO 3 ) 3 Dissolve in a mixed solution of glacial acetic acid, water and formamide at room temperature, and then place the solution for 30 hours to obtain LaNiO with a concentration of 0.3M. 3 Precursor solution

[0045] (2) The LaNiO obtained in step (1) 3 The precursor solution was spin-coated on the p-type GaN substrate using a homogenizer at 6000 rpm for 60 seconds to obtain the first wet film;

[0046] (3) The first wet film prepared in step (2) was first dried at 250°C for 5 minutes, then pyrolyzed at 600°C for 15 minutes, and finally annealed at 800°C in air atmosphere for 10 minutes. Get a layer of LaNiO 3 film;

[0047] (4) Repeat step (2) and step (3) 6 times to obtain LaNiO with 6 layers 3 LaNiO 3 / p-type GaN composite substrate;

[0048] (5) Pb(CH 3 COO) 3 , Ba(CH 3 COO) 2 And C 6 H 9 O 6 La·xH 2 O was dissolved in the first mixed liquid of glacial acetic acid and deionized water at 120℃, and then Zr(OC 3 H 7 ) 4 Dissolve in g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com