Thermal performance analysis method for material with straight cracks or heterogeneous splicing

An analytical method and technology of thermal performance, applied in computer materials science, instrumentation, informatics, etc., to solve problems such as limiting commercial software applications, limiting the validity of results, and limited mathematical models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0070] A method for analyzing thermal properties of materials with straight cracks or heterogeneous splices comprising the steps of:

[0071] A. Analyze the actual physical process of material cracks and heterogeneous splicing problems, analyze the model and make reasonable assumptions:

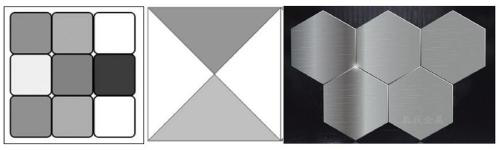

[0072] First, consider a material model with two layers of different media with a clear interface between the different materials, such as Figure 5 , 6 shown;

[0073] For convenience, the steady heat transfer problem is considered first, that is, the temperature reaches a steady state during the transfer process inside the composite material, and the absorption of heat by the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com