An optical fiber connector for high-power laser cable

A fiber optic connector, high-power technology, applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of untimely heat transfer, damage to optical devices and equipment, low efficiency, etc., achieve high thermal conductivity and improve optical loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

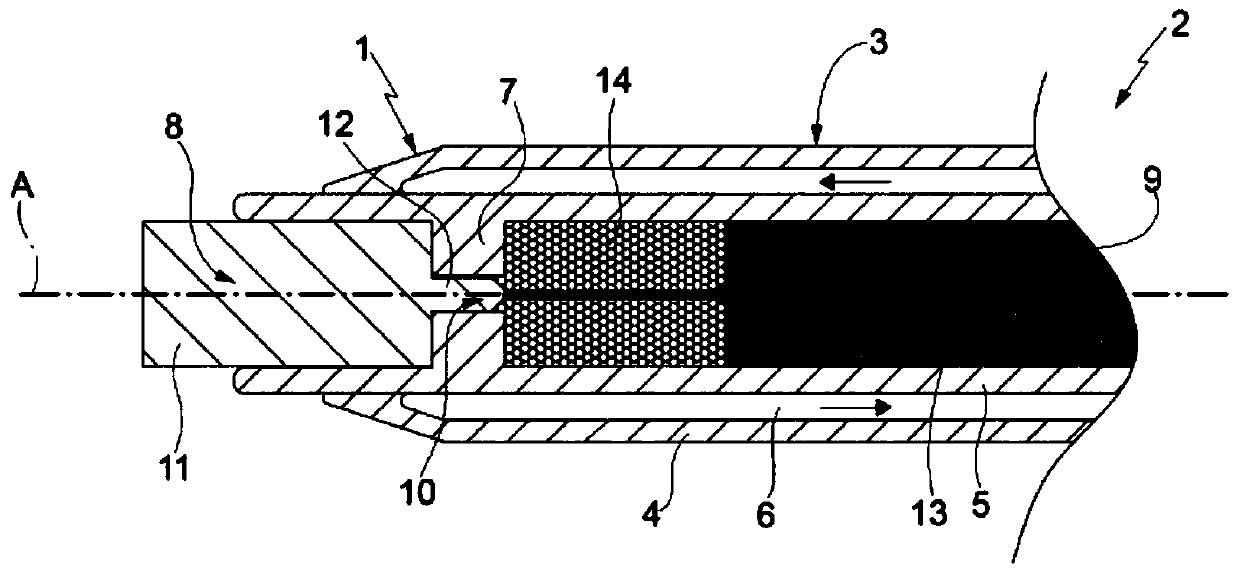

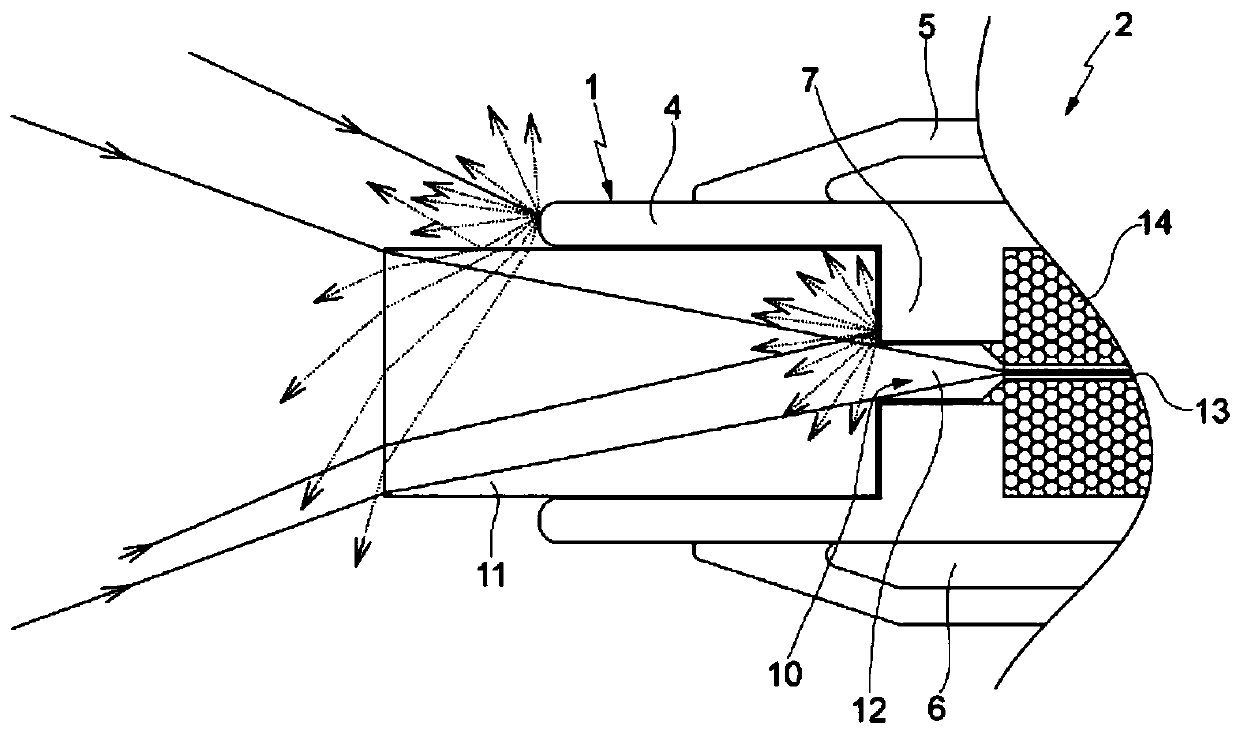

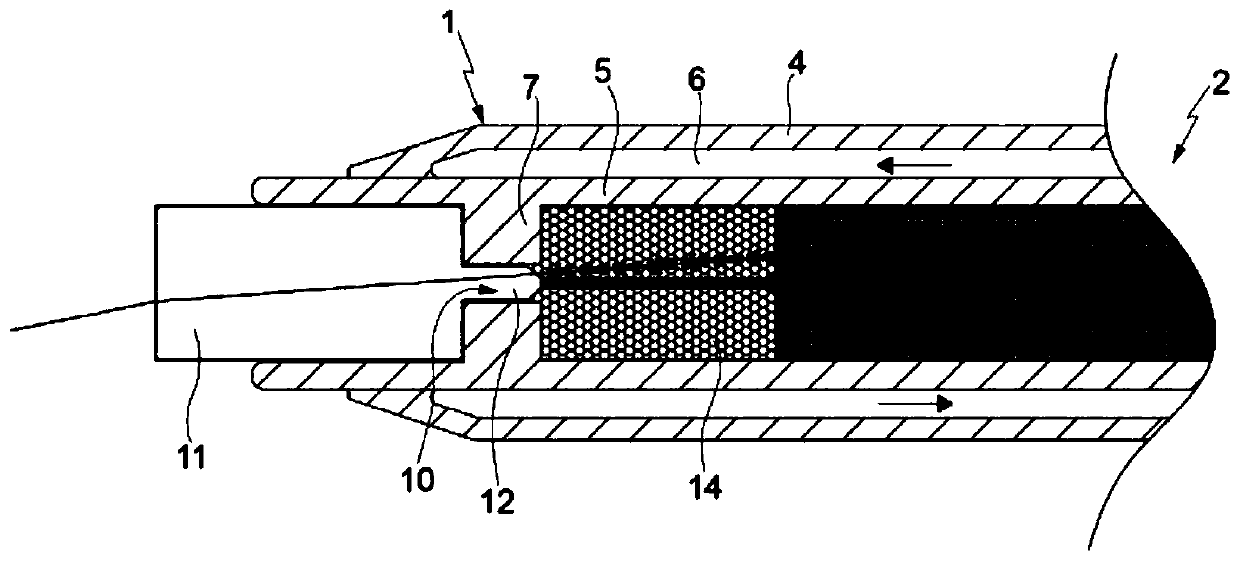

[0025] Such as figure 1 As shown, a fiber optic connector for high-power laser cables of the present invention includes an optical connector body, and the optical connector body includes a sleeve 3; the sleeve 3 includes an inner tube body 5 and an outer tube body 4, The inner tube body 5 is coaxially arranged inside the outer tube body 4, and an annular hollow cavity 6 is formed between the two, which is coaxially arranged with the casing 3 and extends longitudinally. The hollow cavity 6 has an inlet and an outlet to form a cooling cycle , there is a cooling liquid in the hollow cavity 6, according to figure 1 flow in the direction indicated.

[0026] The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com