A method for evaluating the safe state of generator pump-through rotor

A safety state assessment and safety state technology, applied in the manufacture of stator/rotor bodies, instruments, measuring devices, etc., can solve the problems of easy misunderstanding, long working time, low efficiency, etc., to avoid collision danger and reduce monitoring errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

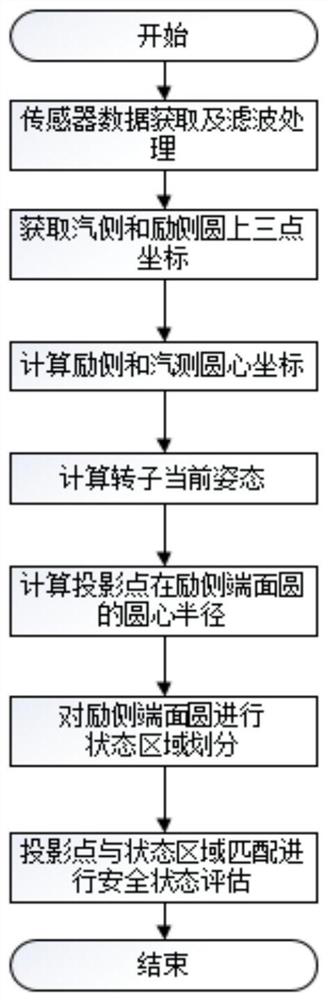

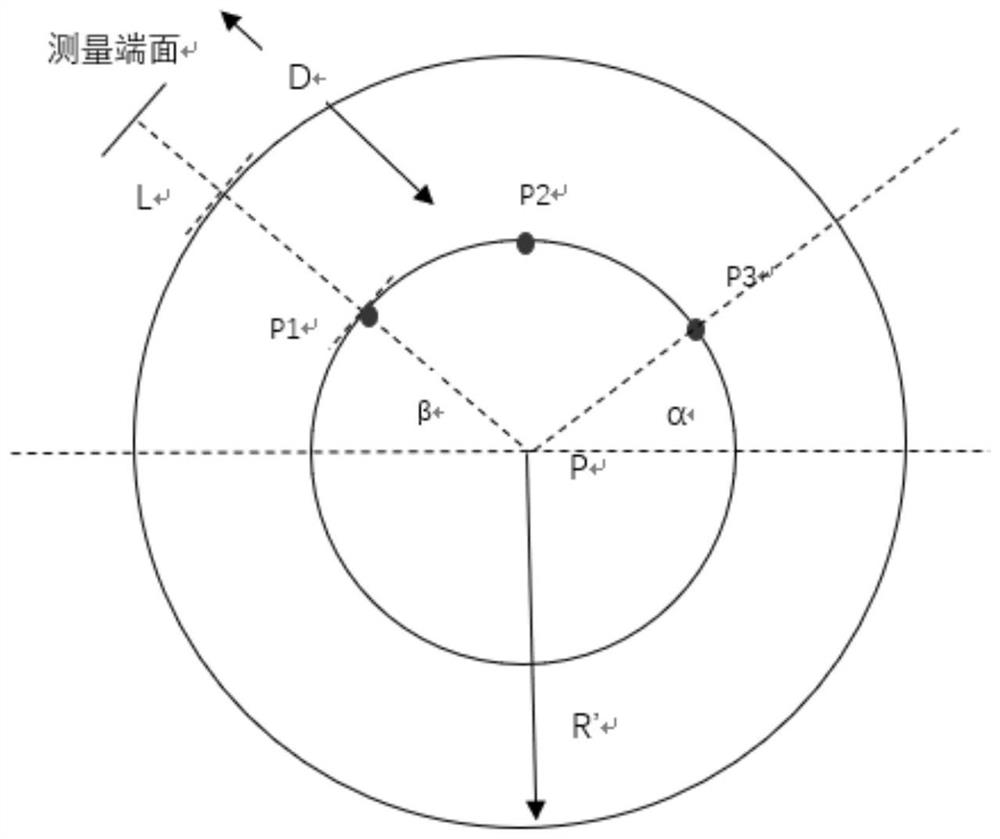

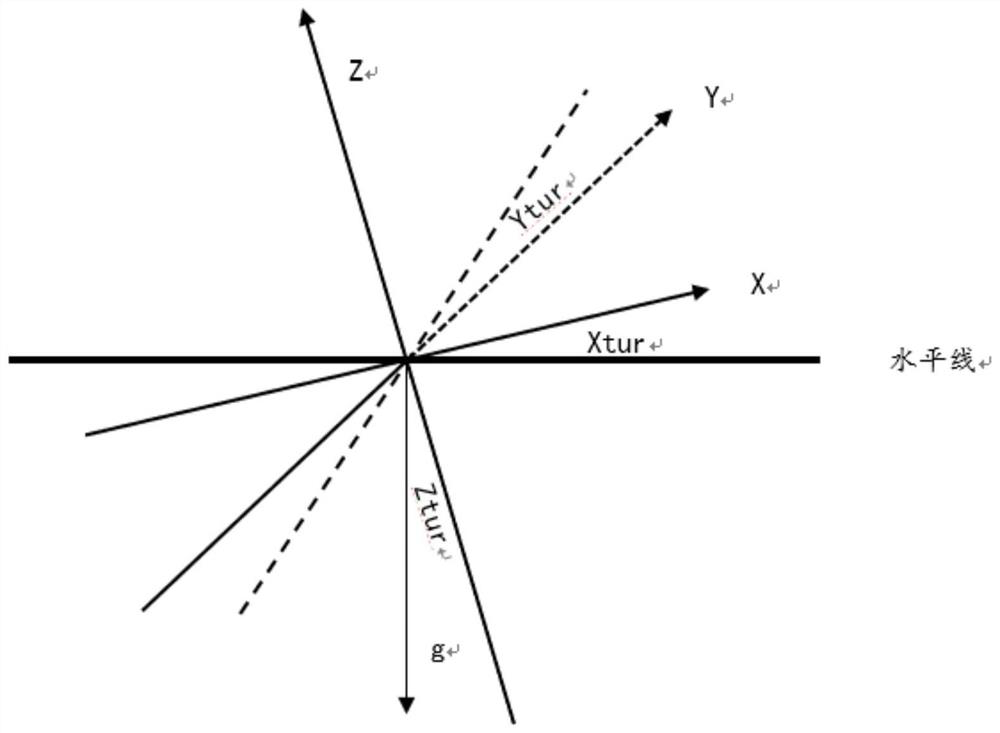

[0034] In this embodiment, the distance sensors arranged on the stator at the excitation side and the rotor at the steam side are used to read the distance data, and then the distance measurement data is filtered to obtain smooth distance data, and then the center of the steam side and the excitation side are calculated according to the center coordinate algorithm. The coordinates of the center of the circle are used to calculate the deflection angle of the rotor based on the data of the three-axis accelerometer. Based on this, according to the design drawing of the rotor, the most critical state points of each cylindrical section of the rotor are spatially project...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com