Resistance adaptive ammunition belt device

A self-adaptive, elastic belt technology, applied in offensive equipment, weapon accessories, barrels, etc., can solve the problems of large motion acceleration, low projectile motion resistance, affecting the air-holding performance of the elastic belt, etc., to improve the launch performance, promote the borehole Internal combustion, the effect of increasing contact stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

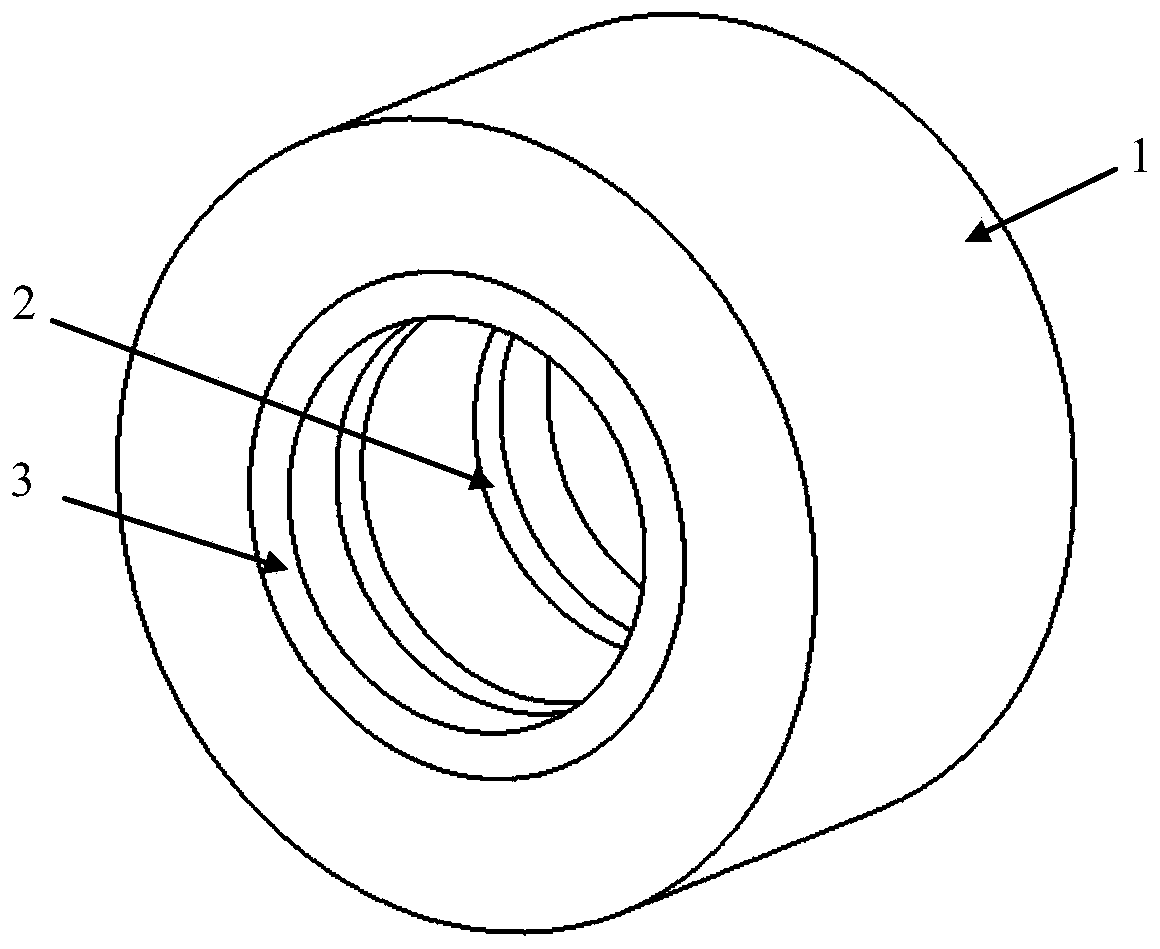

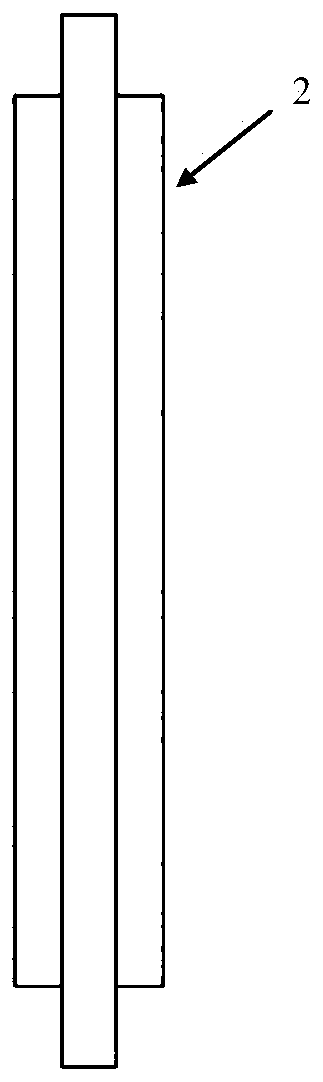

[0019] The invention proposes an elastic belt device for adaptively adjusting the movement resistance of projectiles, which includes an elastic belt main body including two rectangular grooves and a semicircular groove, and two elastic belt bottom brackets including rectangular bosses.

[0020] Such as Figure 1-5 As shown, the resistance adaptive elastic belt device includes an elastic belt main body 1, an elastic belt bottom bracket I2 and an elastic belt bottom bracket II3.

[0021] Limited radial relative sliding can occur between the elastic belt main body 1 and the elastic belt bottom support I2 and the elastic belt bottom support II3.

[0022] There is a T-shaped annular groove on the inner wall of the two end faces of the main body 1 of the belt, and there is a semicircular annular groove on the inner wall of the main body 1 of the belt, which is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com