Biomass air-heating fireplace

A biomass and air heating technology, applied in the field of fireplaces, can solve problems such as coking, structural design differences between boilers and fireplaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

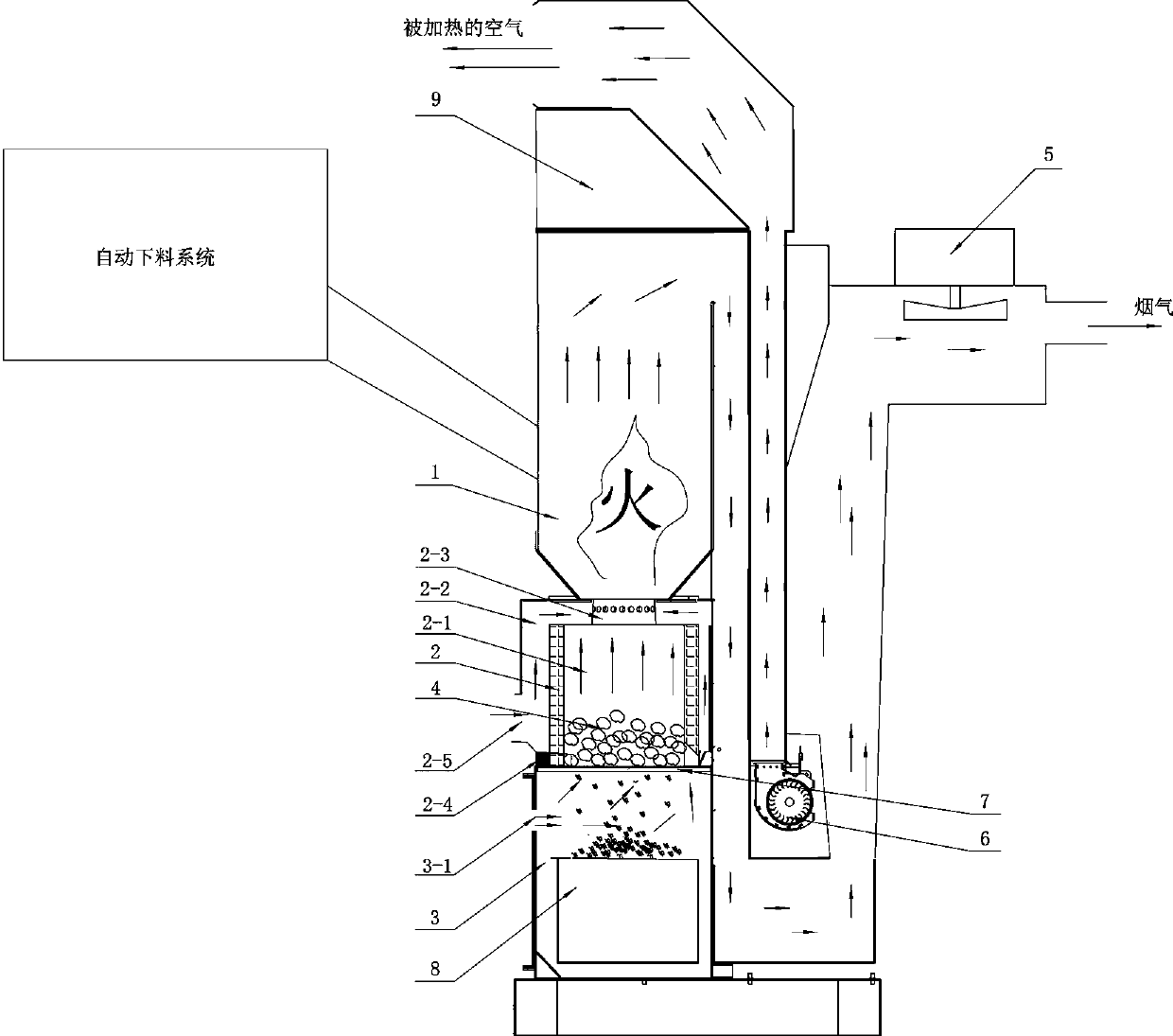

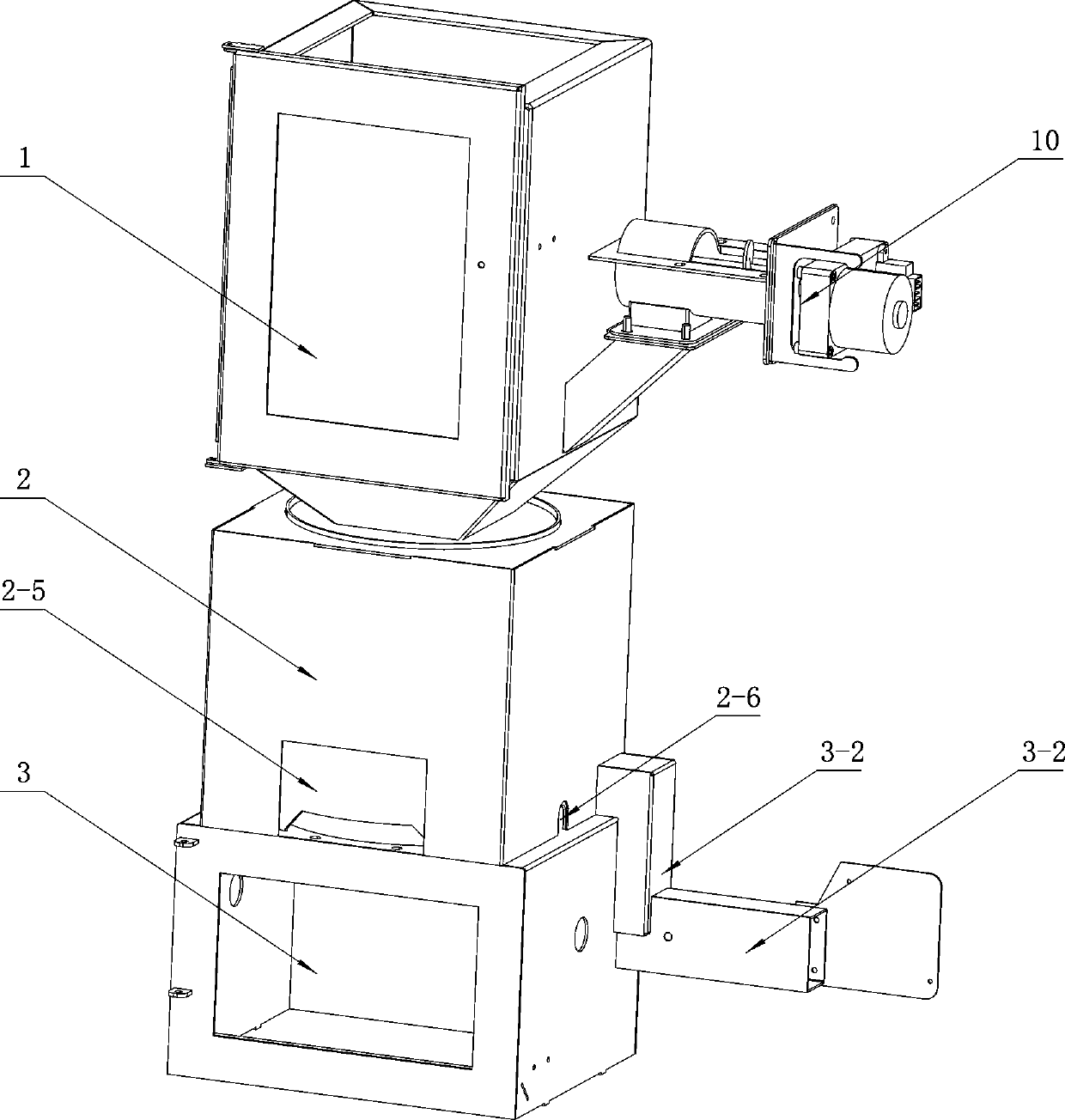

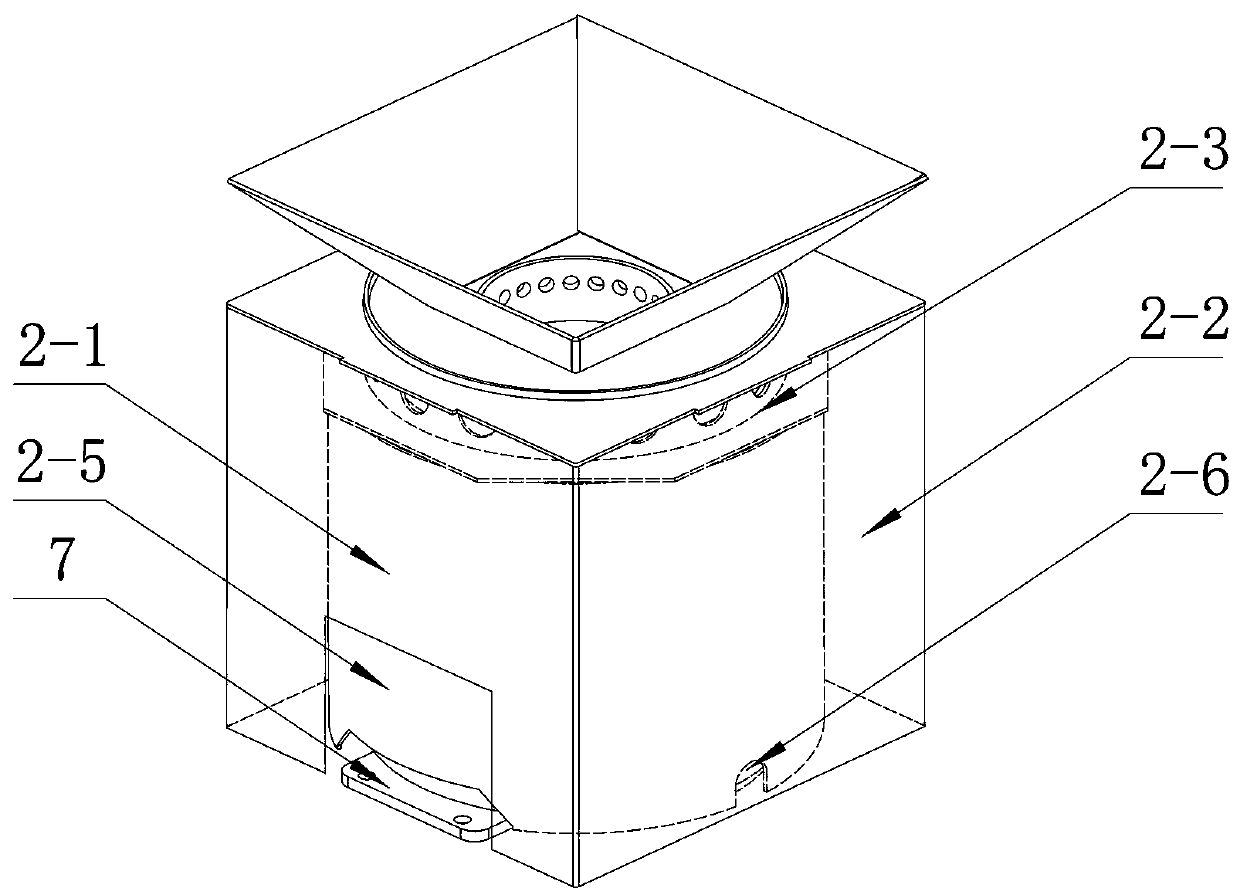

[0025] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

[0026] Such as Figure 1-5 As shown, a biomass air-heated fireplace includes a furnace body, an automatic feeding system, a warm air system and a smoke exhaust system; the furnace body includes an upper combustion chamber 1, a lower combustion chamber 2 and an ash chamber 3; The combustion chamber 2 is arranged above the ash chamber 3 for pyrolyzing the biomass pellet fuel 4 to produce volatile combustible gas; the upper combustion chamber 1 is arranged above the lower combustion chamber 2 for burning volatile Combustible gas; the automatic feeding system is set corresponding to the lower combustion chamber 2; the smoke exhaust system is connected to the upper combustion chamber 1, and the smoke exhaust system includes a smoke exhaust pipe and a smoke exhaust fan 5 arranged. The smoke exhaust pipe communicates with the upper combustion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com