Position adjusting device for cable conveyor for cable laying

A cable conveyor and cable laying technology, applied in the direction of supporting machines, mechanical equipment, machines/supports, etc., can solve the problem of unable to adjust the height of the conveyor smoothly, so as to improve the laying efficiency, reduce manpower and time-consuming, The effect of avoiding duplication of work and manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

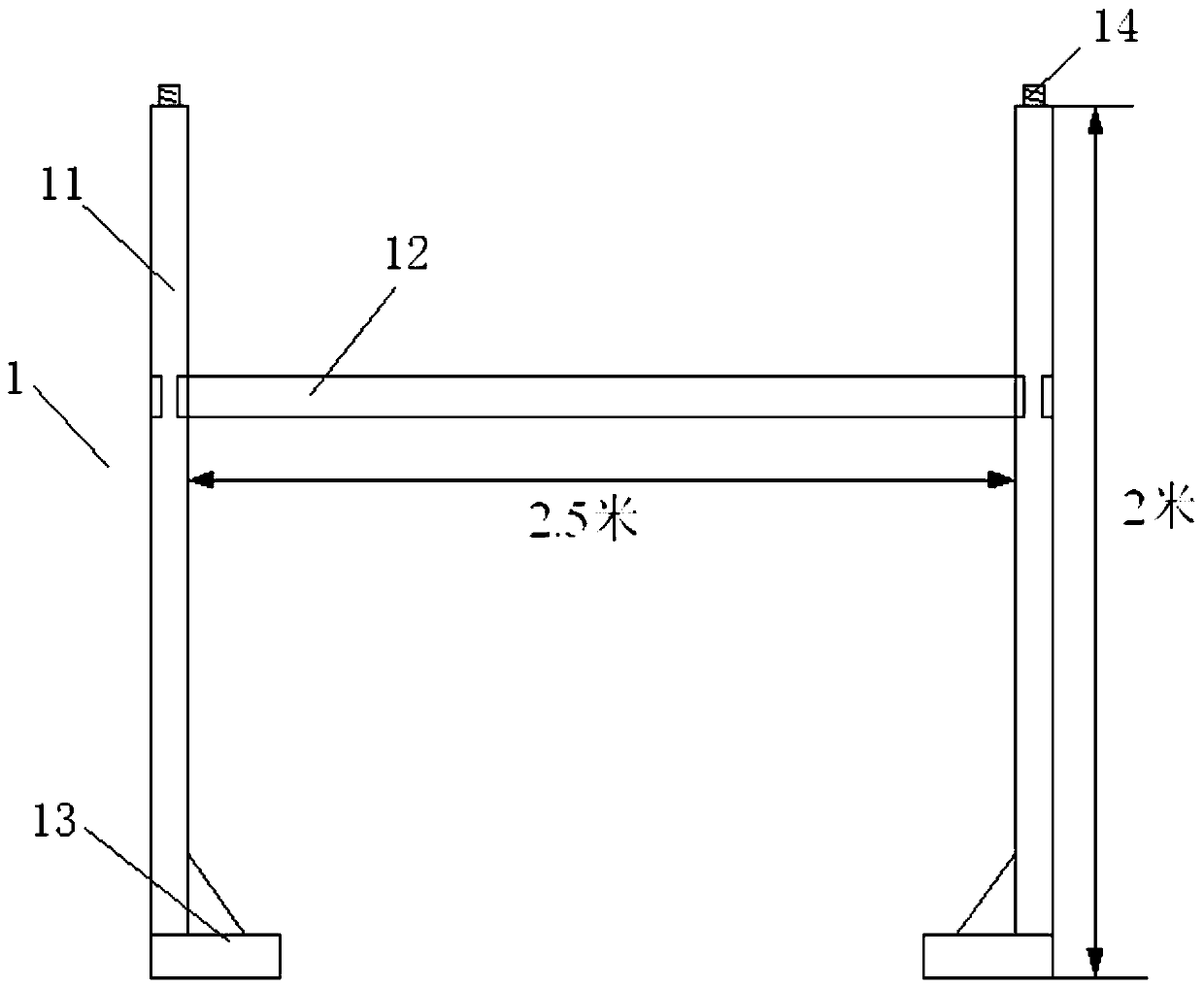

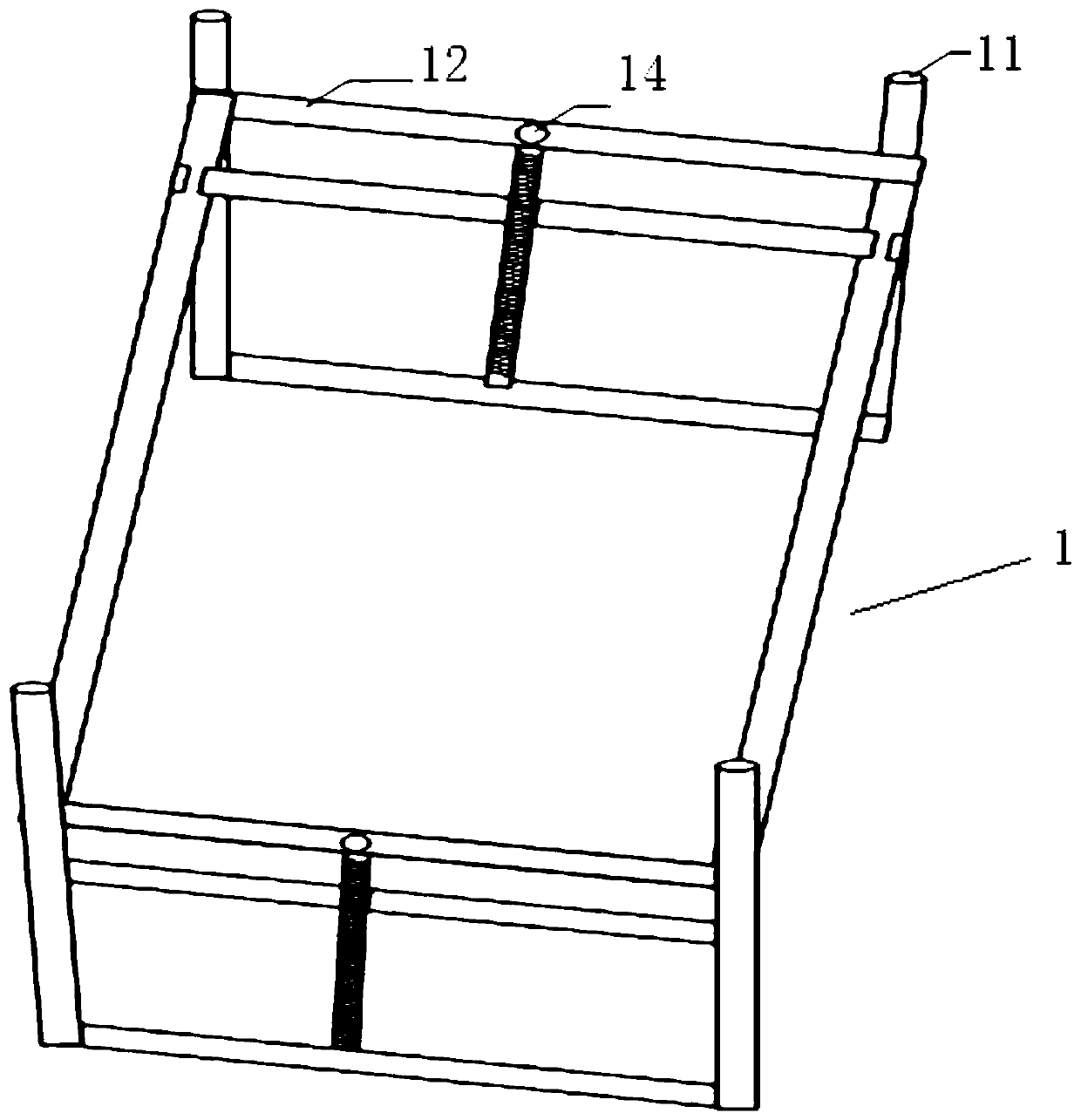

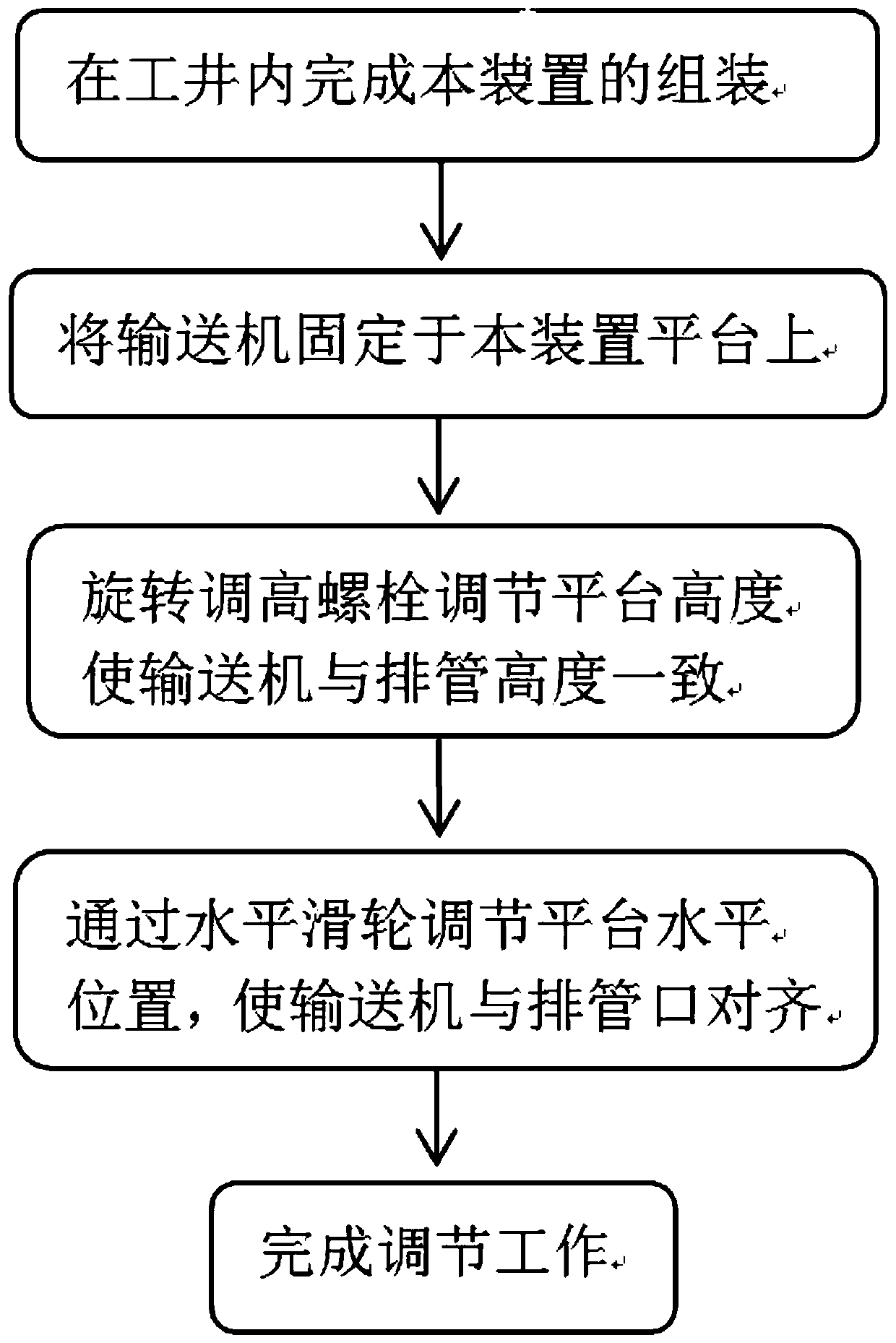

[0033] refer to Figure 1 to Figure 4 As shown, a cable conveyor position adjustment device for cable laying, which includes:

[0034] The mounting bracket 1 includes four uprights 11 arranged at the four corners of a rectangle, a mounting crossbeam 12 connecting two adjacent uprights, and the base of the cable conveyor is supported on the mounting crossbeam;

[0035] The lifting support 2 is fixed with the mounting bracket, so as to realize height adjustment together with the mounting bracket;

[0036] Chassis 3, with rollers 31, is used to realize the overall horizontal position movement of the device, so as to realize the horizontal position adjustment of the cable conveyor;

[0037] The height adjustment structure is used to drive the lifting support up and down, thereby driving the installation bracket up and down, and realizing the height adjustment of the cable conveyor.

[0038] Specifically, the column 11 is made of galvanized steel pipe, and the installation beam 1...

Embodiment 2

[0044] The difference from Embodiment 1 is that, in order to realize automatic adjustment, the height adjustment structure is a hydraulic cylinder 21, and the hydraulic cylinder includes a cylinder body provided with a piston chamber, a piston is arranged in the piston chamber, and the piston is installed It is connected with the piston rod, and the piston rod is connected with the lifting support.

[0045] Wherein, an oil inlet hole is opened on the cylinder block of the oil cylinder, and an oil inlet pipeline is connected to the oil inlet hole, and a solenoid valve for controlling hydraulic oil to enter the piston cavity is arranged on the oil inlet pipeline.

[0046] The hydraulic cylinder 21 is arranged below the central position of the lifting support, and guide sleeves are connected at least at the center positions of both sides of the lifting support. The guide sleeve cooperates with the guide rod 22, and the guide rod is fixed on the chassis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com