A buffer device for transmission

A buffer device and transmission technology, applied in clutches, friction clutches, springs/shock absorbers, etc., can solve the problems of transmission power output shaft impact, damage to the internal structure of the transmission, and a large speed gap between the clutch disc and the friction disc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

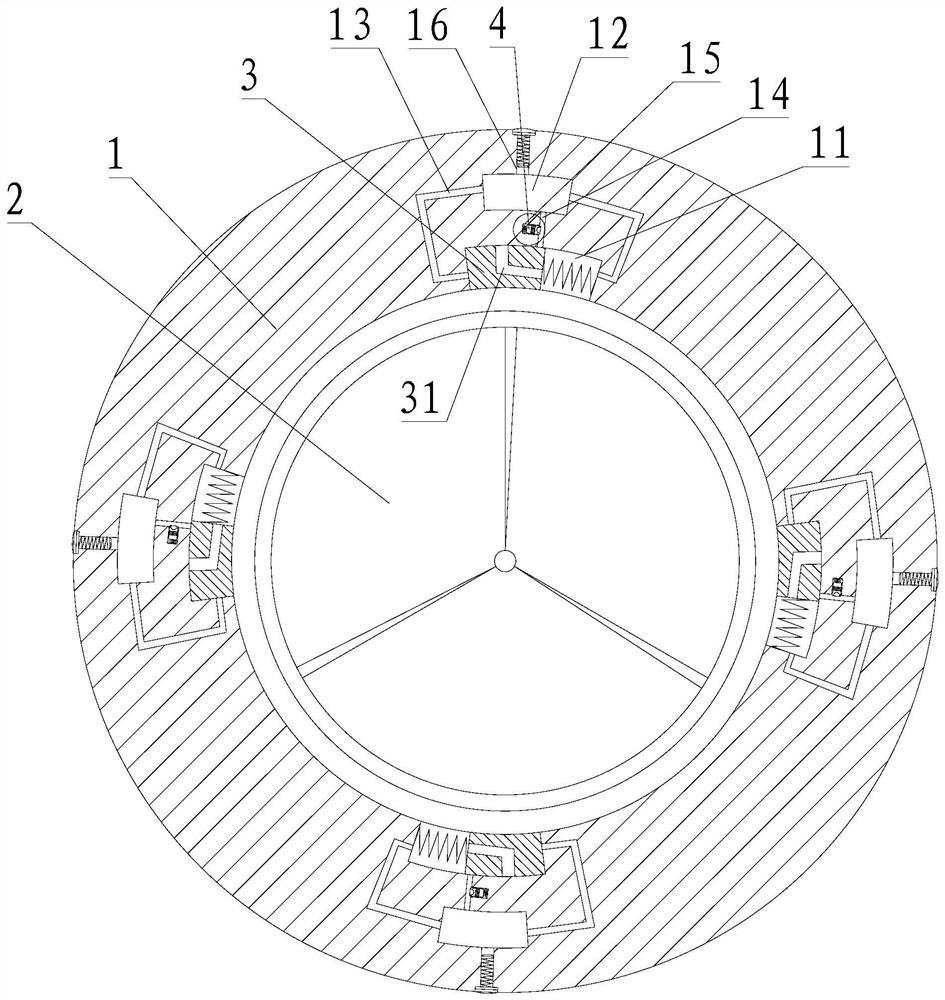

[0040] A buffer device for a transmission, comprising an outer ring 1 and a friction disc 2;

[0041] The friction disc 2 is located in the middle of the outer ring 1, and four buffer blocks 3 are uniformly arranged on the edge of the friction disc 2;

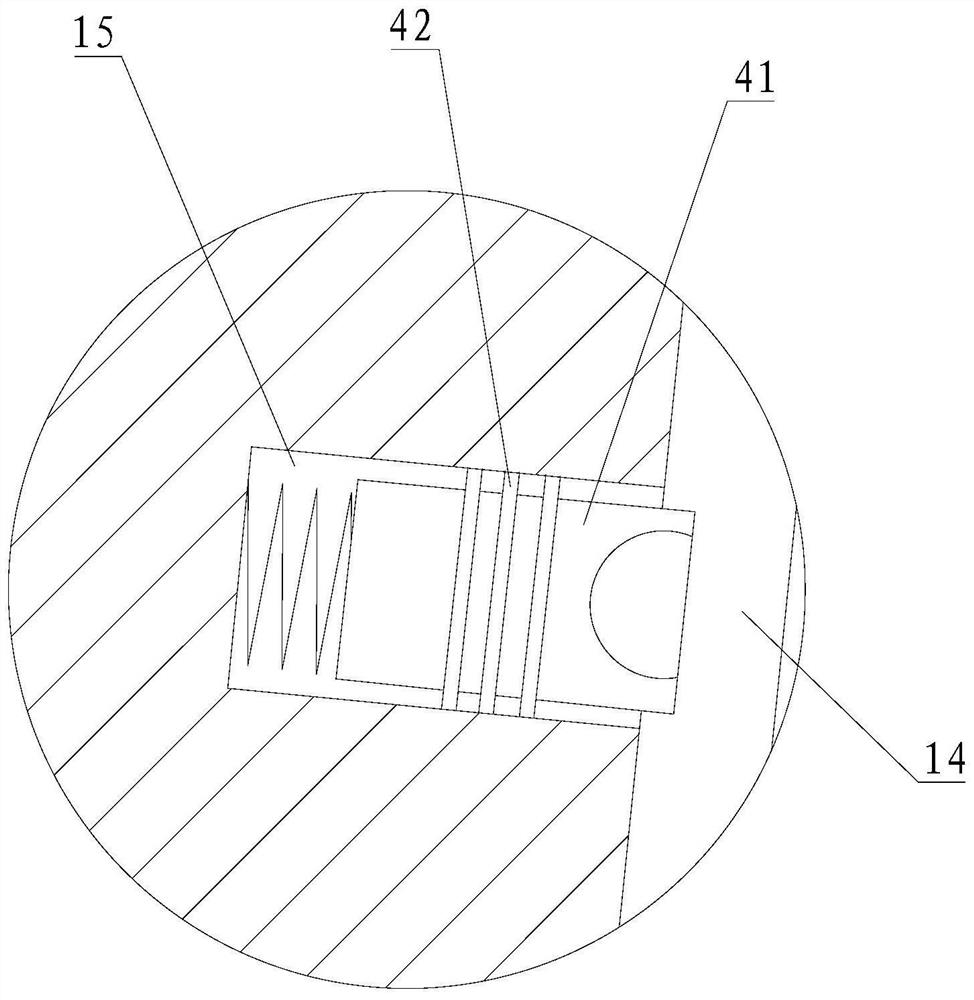

[0042] A buffer chamber 11 corresponding to the buffer block 3 is provided in the outer ring 1, the buffer block 3 is slidably connected in the buffer chamber 11, and one end of the buffer block 3 is elastically connected to the inner wall of the buffer chamber 11 through a spring;

[0043] The inside of the outer ring 1 is also provided with an oil chamber 12 corresponding to the buffer chamber 11. Both ends of the oil chamber 12 communicate with the two ends of the buffer chamber 11 through the first hole 13. There is also a second channel 14 between them, and an oil injection hole 16 is opened on the outer ring 1, and the oil injection hole 16 communicates with the oil chamber 12, and a sealing bolt is arranged in the oil in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com