Built-in cryopump

A low-temperature pump, built-in technology, applied in pumps, liquid displacement machines, machines/engines, etc., can solve the problems of insufficient regeneration, long regeneration time, low absorption speed and absorption limit, etc., and achieve the improvement of the absorption limit , The effect of increasing the effective area and increasing the adsorption speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

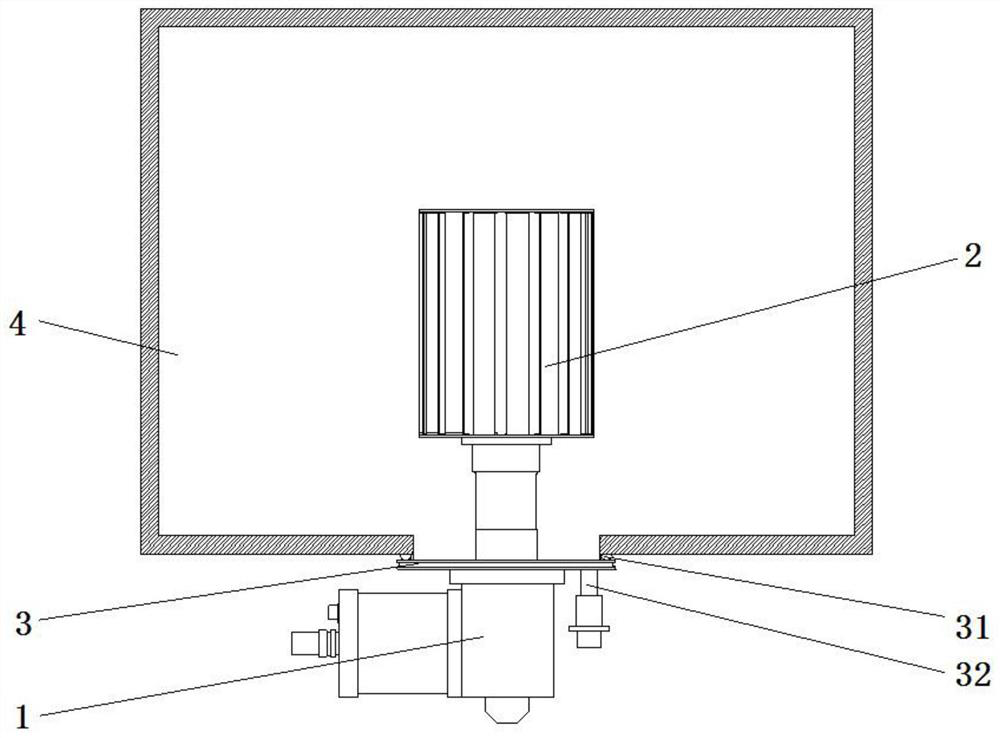

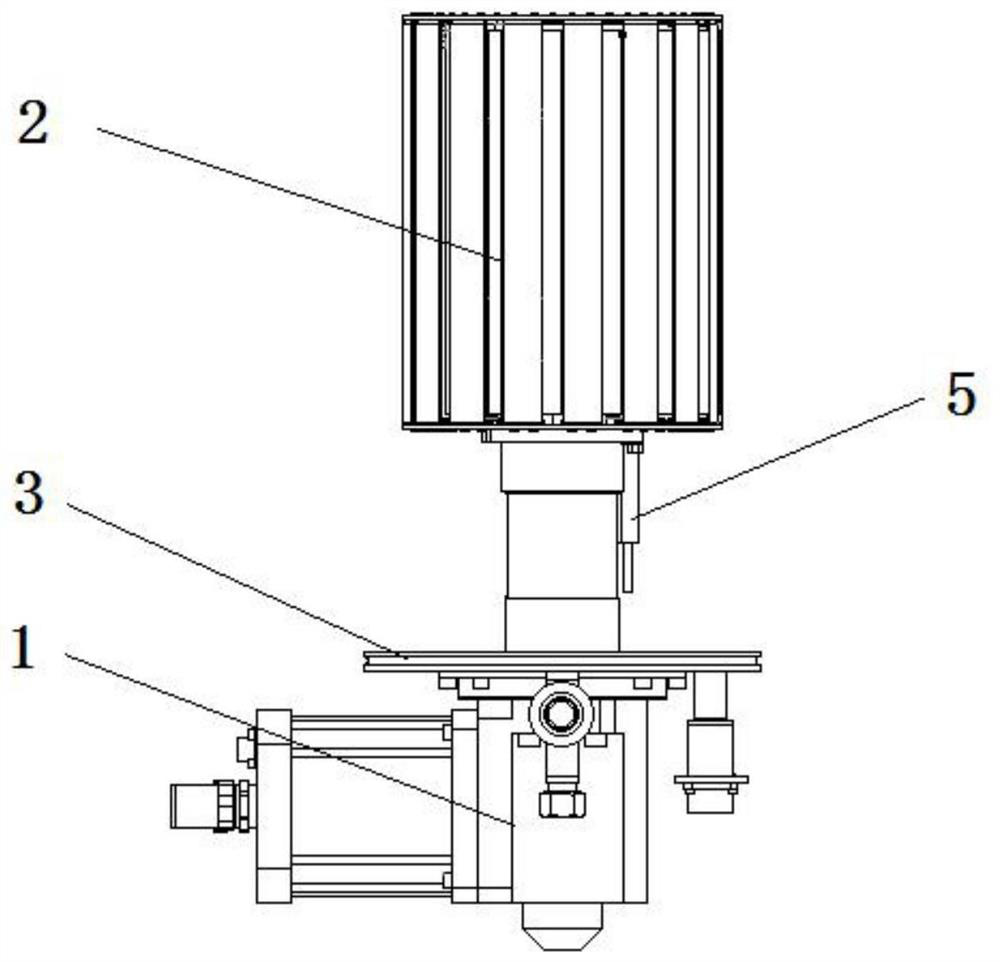

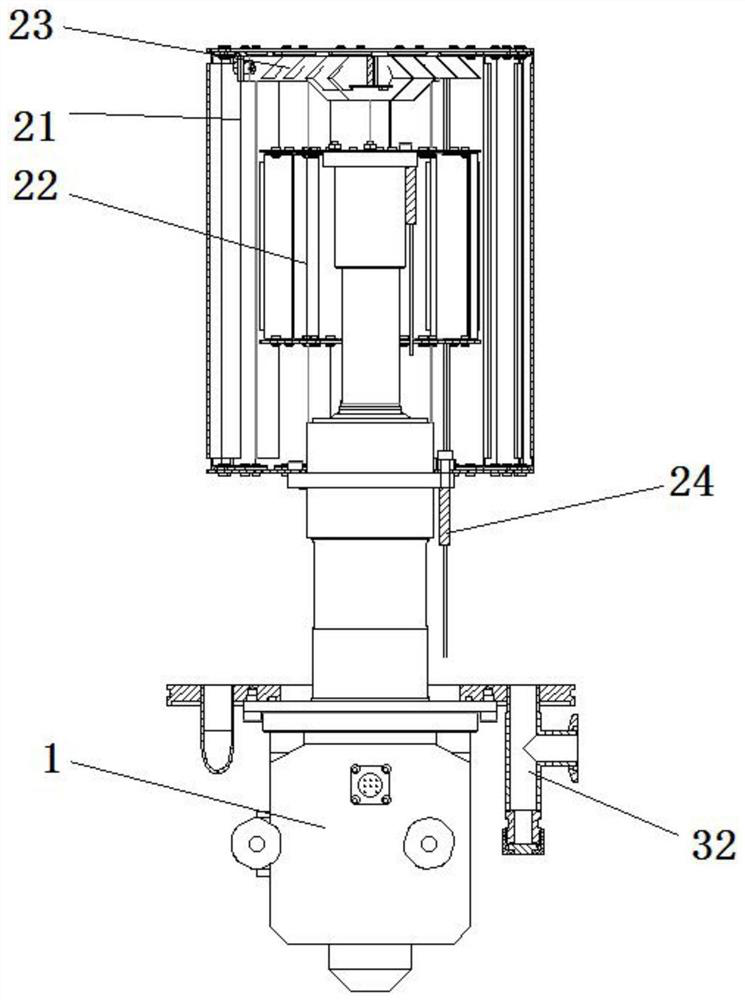

[0035] The built-in cryopump, as shown in the figure, includes a refrigerator 1 and a cold plate assembly 2, the refrigerator 1 is connected to the cold plate assembly 2 and cools the cold plate assembly 2, and also includes a pump port flange 3, the refrigerator 1 and the cold plate The components 2 are fixed on the pump port flange 3, and the pump port flange 3 cooperates with the opening of the vacuum chamber 4 to realize sealing. The cold plate assembly 2 extends into the vacuum chamber 4 and passes through the pump port flange 3 to fix.

[0036] It also includes a heating rod 4 connected to the cold plate assembly 2, and the heating rod 4 is located in the chamber 5 to be vacuumed.

[0037] After abandoning the shell of the traditional cryopump, we regenerate the cryopump with built-in electric heating, and complete the rapid temperature rise of the cold plate by fixing the heating rod 4 directly on the cold head near the cold plate. During regeneration, since there is n...

Embodiment 2

[0046] Same as Embodiment 1, the difference is that the primary cold plate 21 includes a primary base plate 211 and a plurality of primary louvers 212, the primary base plate 211 is an annular plate or a circular plate, and the primary louver plates 212 are placed vertically and circled Fixed on the primary bottom plate 211, the primary bottom plate 211 is provided with a plurality of first bottom plate holes, the first bottom plate holes are in groups of two, each group of first bottom plate holes corresponds to a primary louver 212, and the primary louver 212 It is fixed on the primary bottom plate 211 through the rivets matched with the holes of the first bottom plate.

[0047] Each primary louver 212 includes a first plate 2121 and a second plate 2122, the angle between the first plate 2121 and the second plate 2122 is 135° and the angle is defined as the inner angle of the primary louver 212, The inner corners of the primary louvers 212 are set inwards towards the central...

Embodiment 3

[0055] Same as Embodiment 1, the difference is that the secondary cold plate 22 includes a fixed plate 221 and a plurality of secondary louvers 222, the secondary bottom plate 221 is an annular plate or a circular plate, and the secondary louvers 222 are vertically placed and fixed on the circumference On the secondary bottom plate 221, a plurality of second bottom plate holes are arranged on the secondary bottom plate 221, and the second bottom plate holes are in groups of two, and each group of second bottom plate holes corresponds to a secondary louver 222, and the secondary louver 22 passes through The rivets matched with the holes of the second bottom plate are fixed on the secondary bottom plate 221 .

[0056] Each secondary louver 222 includes a third plate 2221 and a fourth plate 2222, the angle between the third plate 2221 and the fourth plate 2222 is 125° and the angle is defined as the inner angle of the secondary louver 222, The inner corners of the secondary louve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com