Shape memory alloy driving device

A technology of memory alloy and driving device, which is applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve the problems of low thermal conductivity of paraffin wax, long response time of the driver, etc., and achieve the effect of easy restoration of the original state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

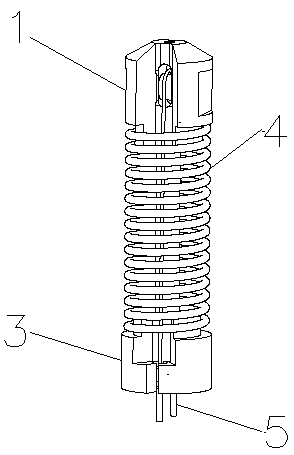

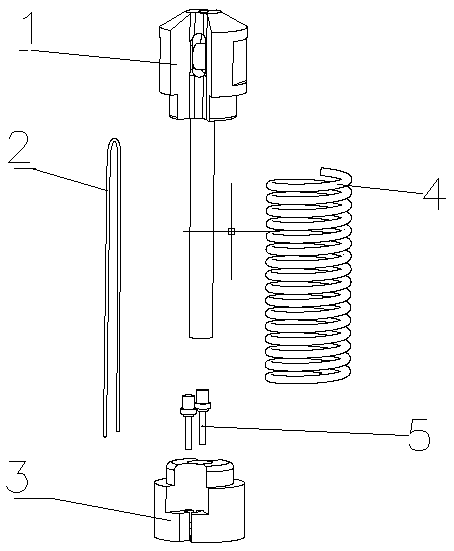

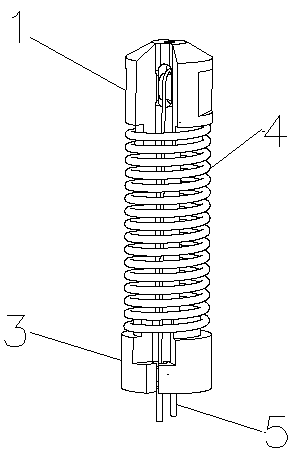

[0013] Such as figure 1 , figure 2 As shown, a shape memory alloy driving device includes an output end 1, a TiNi shape memory alloy wire 2, a base 3, and a compression spring 4. A connecting rod is arranged at the bottom of the output end 1, and a compression spring 4 is set on the connecting rod, and the bottom end of the connecting rod is Inserted into the central socket of the base 3, the TiNi shape memory alloy wire 2 is an inverted U-shaped structure, the upper part of the TiNi shape memory alloy wire 2 is connected to the output end 1, and the lower two ends of the TiNi shape memory alloy wire 2 run through the base 3 Afterwards, they are respectively connected to the positive and negative poles of the power supply to form a closed loop. Two installation holes are symmetrically arranged on the base 3, and contacts 5 are respectively arranged on the installation holes. The two ends of the lower part of the wire 2 are connected, the lower part of the contact 5 is respec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com