Multi-cylinder internal combustion engine device

A multi-cylinder internal combustion engine and inner ring technology, applied in the field of power machinery, can solve problems affecting the reliability of engine pistons, large structural changes, unfavorable mass production, etc., and achieve the effects of low noise, simple movement form, and low processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

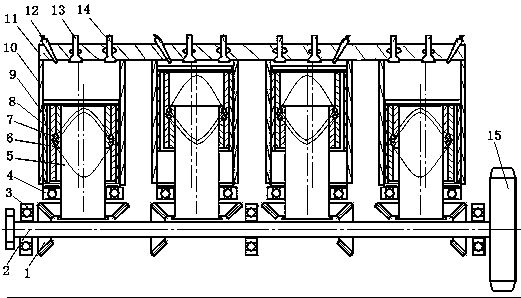

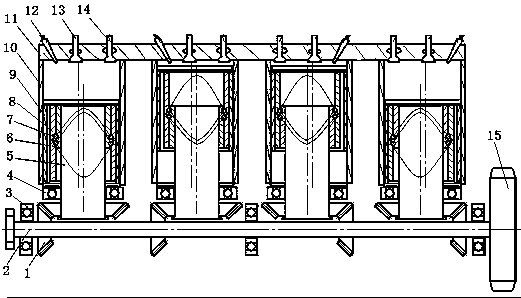

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as figure 1 As shown, the multi-cylinder internal combustion engine device disclosed by the present invention consists of a bevel gear set 1, a main shaft 2, a main shaft bearing 3, a mandrel bearing 4, a mandrel 5, an inner ring 6, a steel ball group 7, an outer ring group 8, and a piston 9, Cylinder 10, cylinder head 11, spark plug or fuel injection nozzle 12, intake valve 13, exhaust valve 14, inertia wheel 15 and frame; main shaft 2 is installed horizontally, and is symmetrically arranged and fixedly connected to the vertical gear of bevel gear set 1 ; The horizontal gear of the bevel gear set 1 is fixedly connected with the mandrel 4; the mandrel 4 is fixedly connected with the inner ring 6; the outer ring group 8 is eccentrically connected with the piston 9; when the piston 9 reciprocates in the cylinder 10, it drives the curved groove The outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com