Grouting construction treatment method

A treatment method and grouting technology, which are used in earth-moving drilling, wellbore lining, tunnel lining, etc., can solve the problems of the grouting pressure not meeting the design requirements, the small diffusion range of the slurry, and the poor grouting effect. The diffusion range is large, the grouting effect is good, and the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

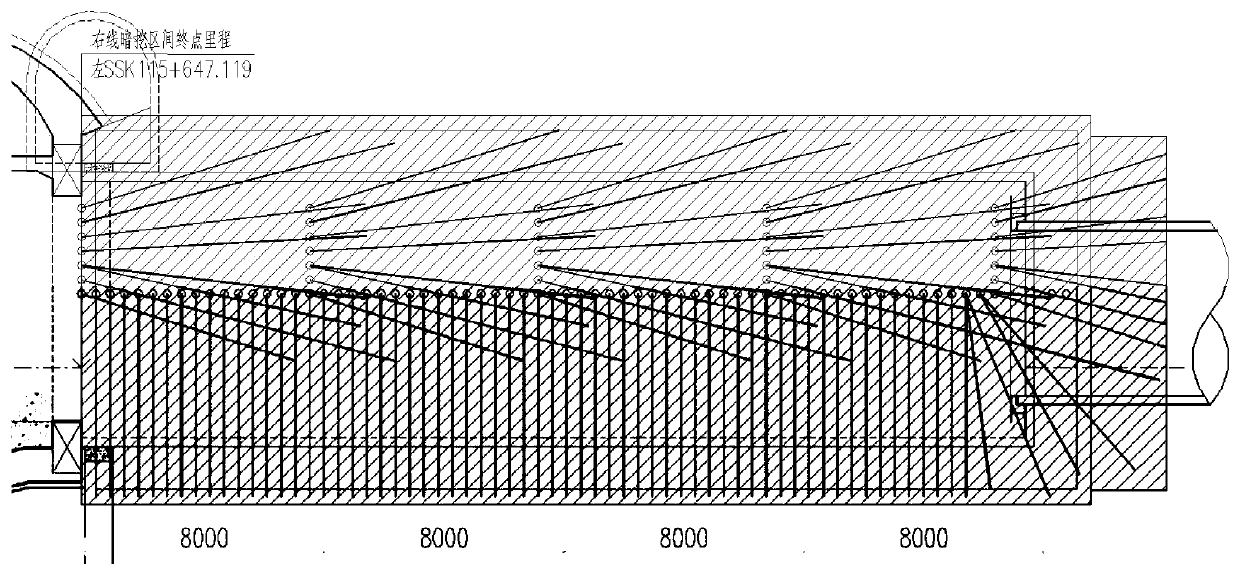

Image

Examples

Embodiment 1

[0094] 1. Grouting parameters:

[0095] 1. Slurry diffusion radius: R=500mm for deep hole grouting;

[0096] 2. Grouting pressure: The initial pressure for deep hole grouting is 0.3-0.75MPa, and the final pressure is 1.0MPa. Under the final pressure state, when the grouting volume per minute is less than 3L or the grouting pressure gradually increases under the final pressure state Grouting can be stopped;

[0097] 3. Grouting slurry: the grouting material is cement-water glass slurry, and the setting time of the slurry is within 1 to 2 minutes;

[0098] Second, the grout wall construction:

[0099] 1. The initial section of grouting adopts the existing structure as the grouting wall.

[0100] 2. After the construction in the tunnel, temporary sealing shall be carried out. The sealing form is the same as the permanent sealing of the tunnel, and the thickness of the sealing shall not be less than 500mm.

[0101] Three, lead hole construction:

[0102] The grouting hole is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com