Light composite type wide-frequency-band sound absorber

A composite, wide-band technology, applied in the field of sound absorption and noise reduction, can solve the problems of increasing the cost of the sandwich structure and achieve the effect of improving the sound absorption effect and noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

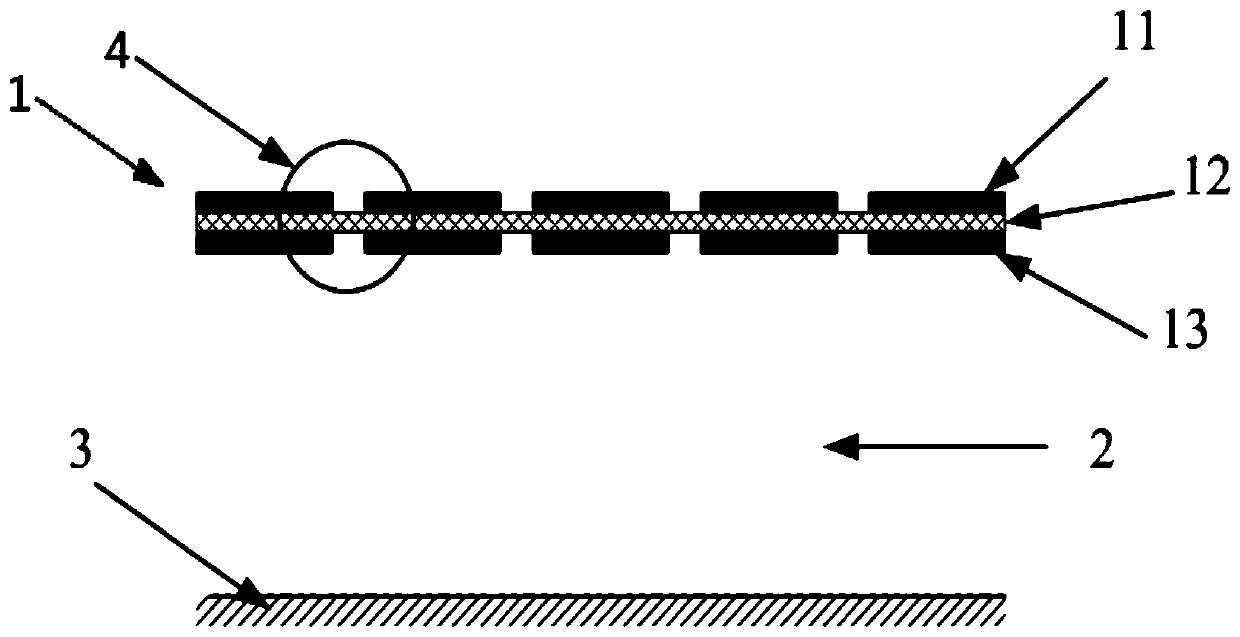

[0028] The present invention provides a side view of an example of a lightweight composite broadband sound absorbing body, such as figure 1 As shown, the micro-perforated composite panel is a sandwich structure filled with extremely thin porous materials. The lightweight composite micro-perforated panel sound absorber includes a micro-perforated composite panel 1 and a rigid backing wall 3; the micro-perforated composite panel 1 is composed of a micro-perforated front panel 11, a porous material 12 and a micro-perforated rear panel 13 after being glued together; Both the micro-perforated front panel 11 and the micro-perforated rear panel 13 are provided with sound-absorbing holes, and the direction of the holes is perpendicular to the panel surface, and may also have a certain inclinatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com