Drilled pile construction method

A construction method and technology of bored piles, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as troublesome, long construction period of bored piles, etc., and achieve the effects of stable turning, shortened construction period, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0044] Example.

[0045] A construction method for bored piles, comprising the steps of:

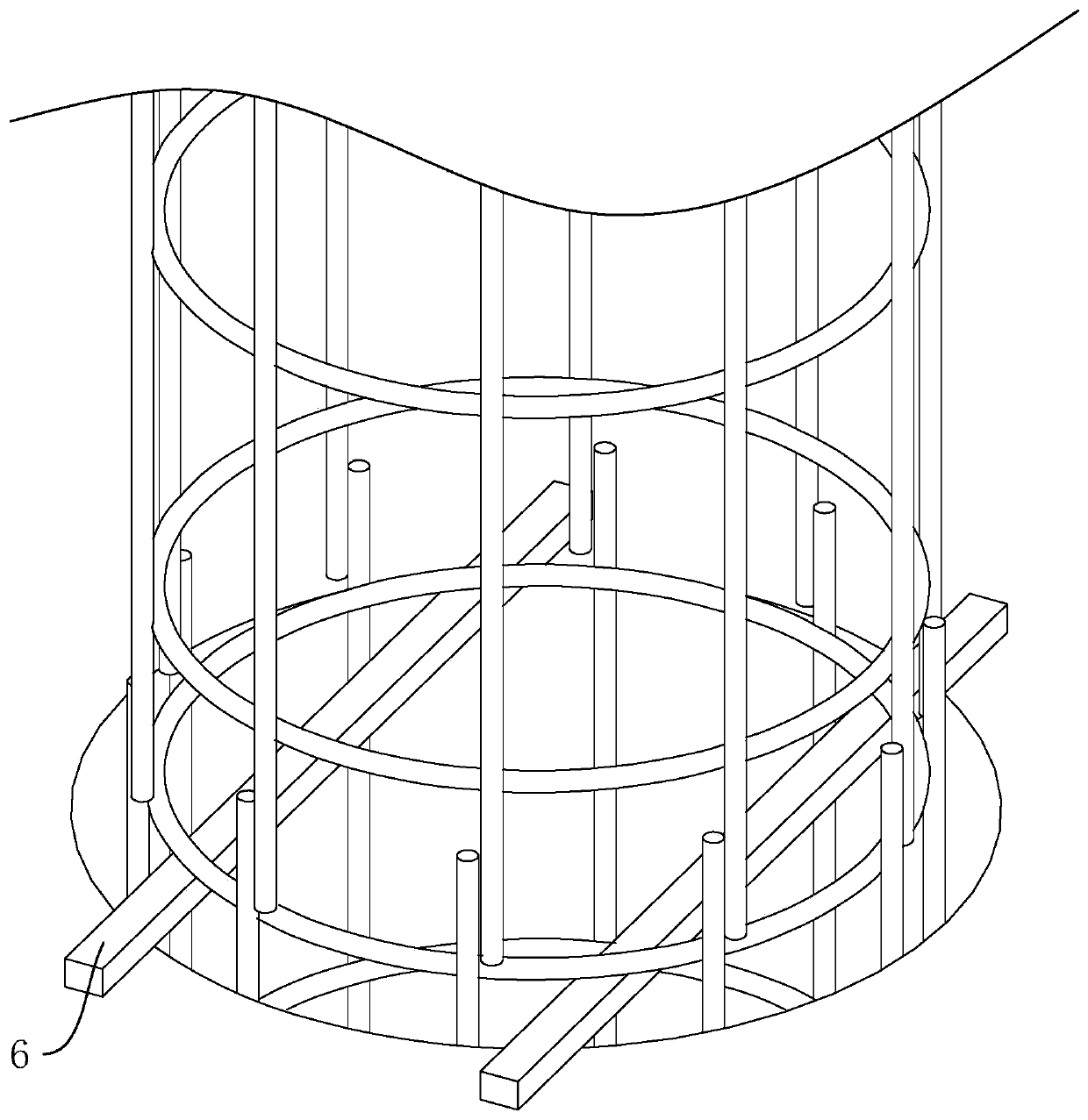

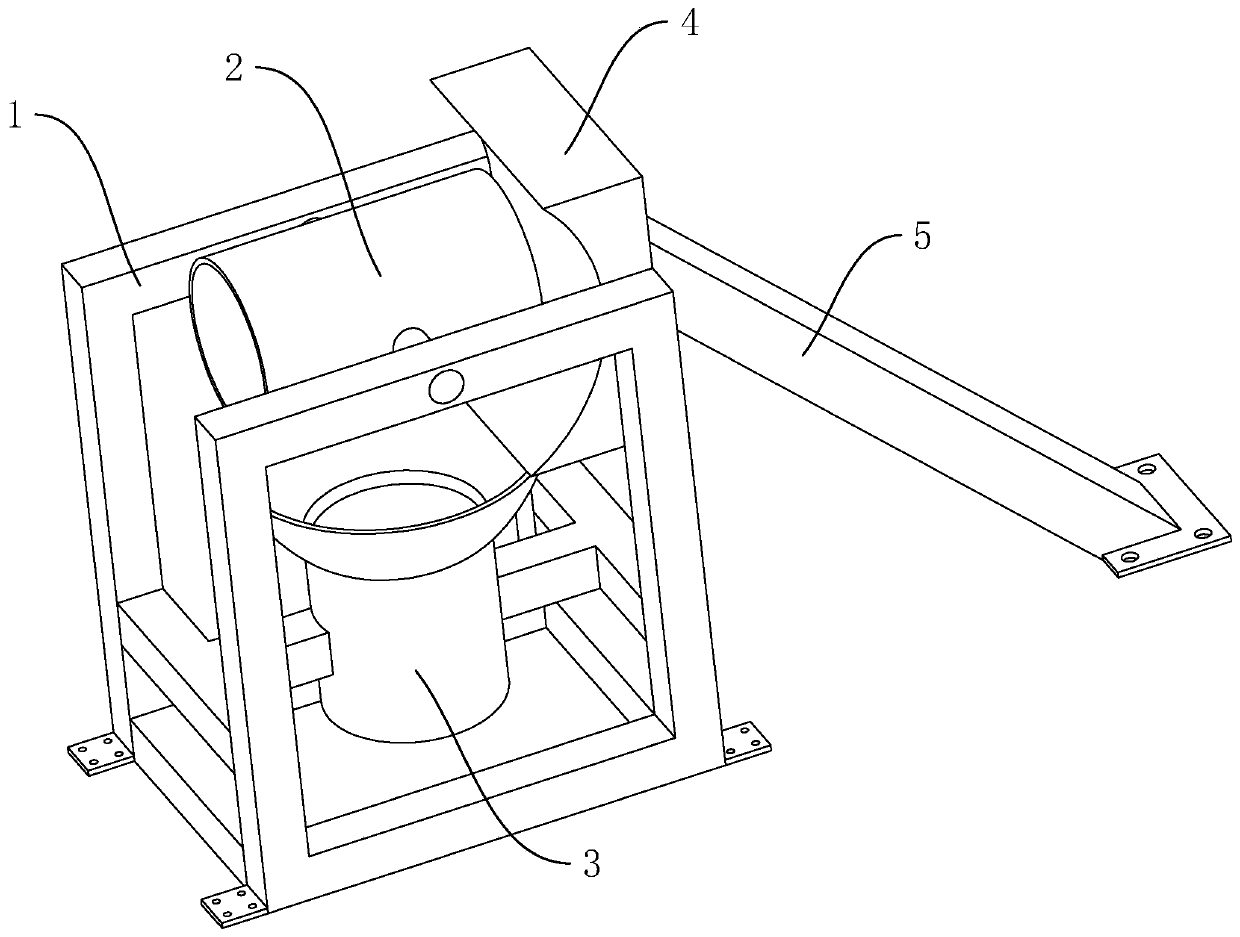

[0046] S1, construction preparation, leveling the construction site, doing survey and setting out, completing the positioning of bored piles, connecting water and electricity, creating good conditions for the drilling rig to enter the site, drilling rig, crane, vibrating hammer, protection Barrels, reinforcement cages and various related materials are ready in place.

[0047]S2, bury the casing, dig a pit with a depth of at least 0.5m at the hole position, the diameter of the pit is larger than the outer diameter of the casing, press the casing into the soil with a vibrating hammer, set the upper end of the casing higher than the ground, and fill it evenly with clay Fully tamp the pit on the outer wall of the casing.

[0048] S3, mud pool setting, dig mud poo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com