Chromium-free leather tanning method

A chrome leather and tanning technology, which is applied in the field of leather preparation, can solve the problems of low leather shrinkage temperature, poor leather tanning effect, and limit the application of chrome-free tanning, and achieve good tanning effect and high shrinkage temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of an organic chlorine tanning agent containing a salicylic acid structure, comprising the following steps:

[0020] Step 1: 60g deionized water and 15.3g 4-aminosalicylic acid are added to the reaction vessel and stirred and mixed, and the first mixed solution is formed after mixing; then the pH of the first mixed solution is adjusted with 20% aqueous sodium bicarbonate solution Adjust to 6.5~7.0;

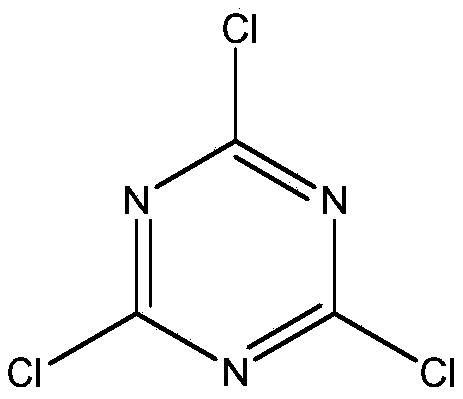

[0021] Step 2: Under the condition that the temperature is 0° C., 18.4 g of cyanuric chloride is added to the first mixed solution for reaction, and at the same time, the pH of the reaction system is adjusted to 6.0 to 6.5 with 20% aqueous sodium bicarbonate solution, and the reaction The time is 5 hours, and the organic chlorine tanning agent is obtained after the reaction is completed.

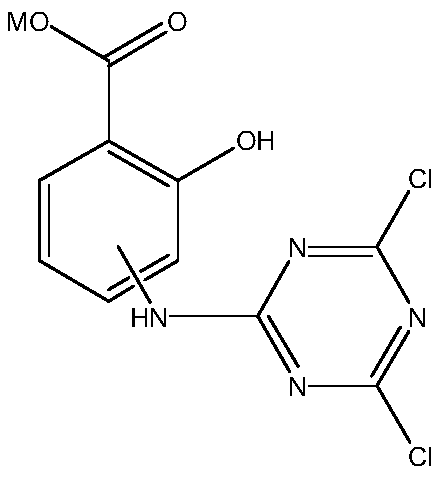

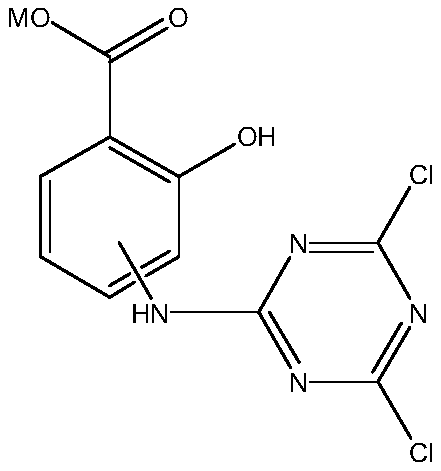

[0022] The structural formula of the 4-aminosalicylic acid is

[0023] The structural formula of the cyanuric chloride is

[0024]

[0025] The structural for...

Embodiment 2

[0030] A preparation method of an organic chlorine tanning agent containing a salicylic acid structure, comprising the following steps:

[0031] Step 1: 60g of deionized water and 15.3g of 3-aminosalicylic acid are added to the reaction vessel and stirred and mixed, and the first mixed solution is formed after mixing; then the pH of the first mixed solution is adjusted with 20% sodium carbonate aqueous solution to 6.5~7.0;

[0032] Step 2: Under the condition that the temperature is 0°C, 18.4g of cyanuric chloride is added to the first mixed solution for reaction, and at the same time, the pH of the reaction system is adjusted to 6.0-6.5 with 20% aqueous sodium carbonate solution, and the reaction time is For 5h, the organic chlorine tanning agent is obtained after the reaction.

[0033] The structural formula of 3-aminosalicylic acid is

[0034]

[0035] The structural formula of organic chlorine tanning agent is

[0036]

[0037] Its reaction formula is:

[0038] ...

Embodiment 3

[0040] A preparation method of an organic chlorine tanning agent containing a salicylic acid structure, comprising the following steps:

[0041] Step 1: 60g deionized water and 15.3g 5-aminosalicylic acid are added to the reaction vessel and stirred and mixed, and the first mixed solution is formed after mixing; then the pH of the first mixed solution is adjusted with 20% potassium hydroxide aqueous solution Adjust to 6.5~7.0;

[0042] Step 2: Under the condition that the temperature is 0° C., 18.4 g of cyanuric chloride is added to the first mixed liquid for reaction, and at the same time, the pH of the reaction system is adjusted to 6.0 to 6.5 with 20% potassium hydroxide aqueous solution, and the reaction The time is 5 hours, and the organic chlorine tanning agent is obtained after the reaction is completed.

[0043] The structural formula of 5-aminosalicylic acid is

[0044]

[0045] The structural formula of organic chlorine tanning agent is

[0046]

[0047] Its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shrinkage temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com