A robot filling potted flower system

A technology of robots and potted flowers, applied in the field of fireworks production, can solve the problems of restricting the production capacity of fireworks production enterprises, the harsh and dangerous working environment of workers, affecting product quality, etc., and achieve the effects of reducing static electricity hazards, quantitatively controllable quality, and simple and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

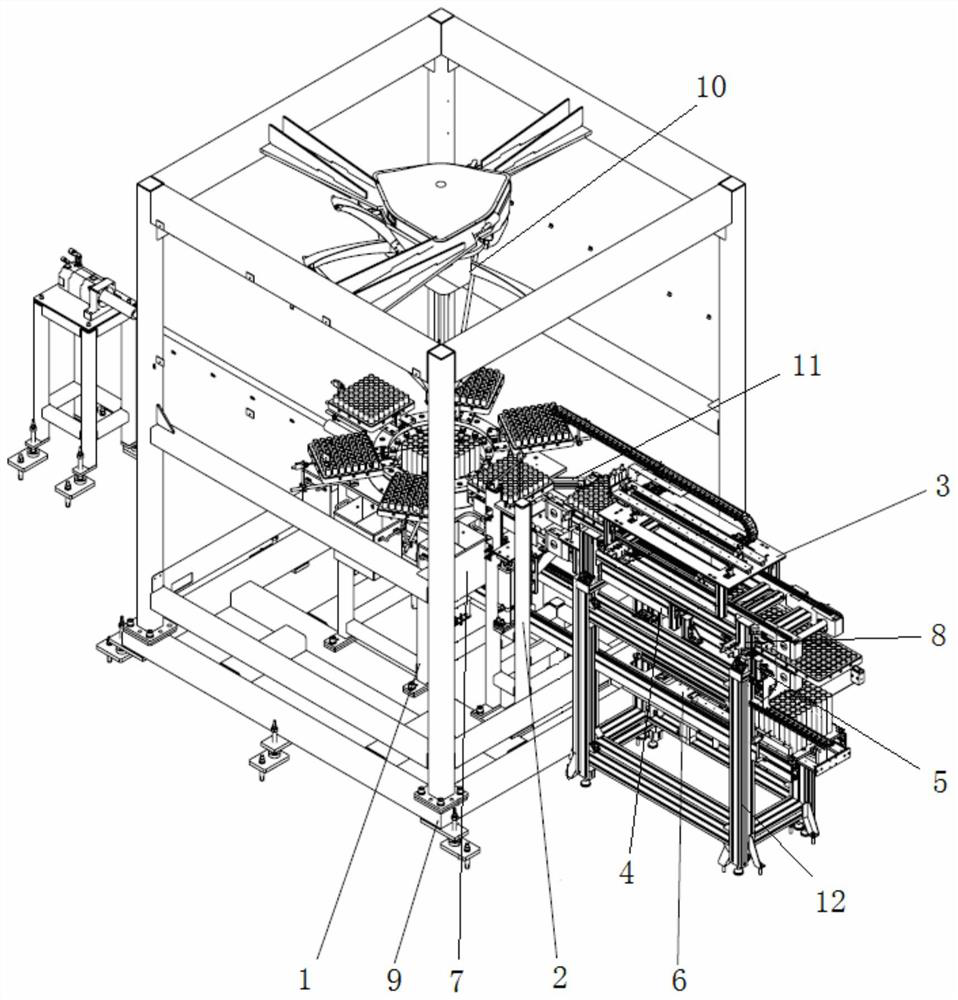

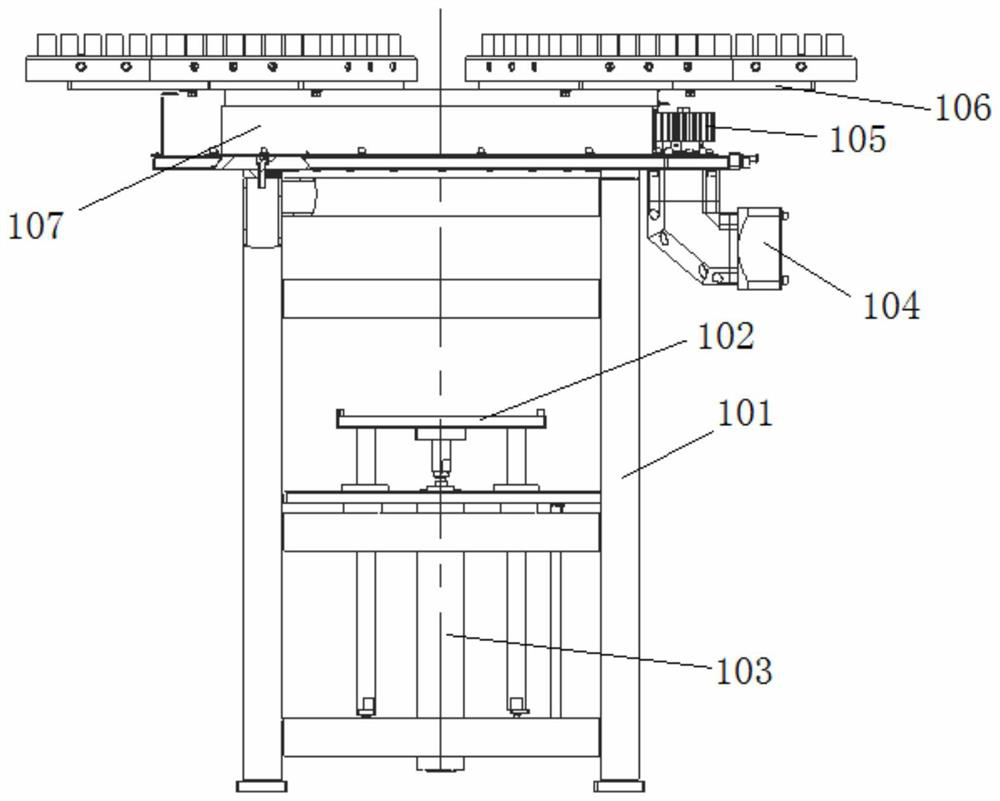

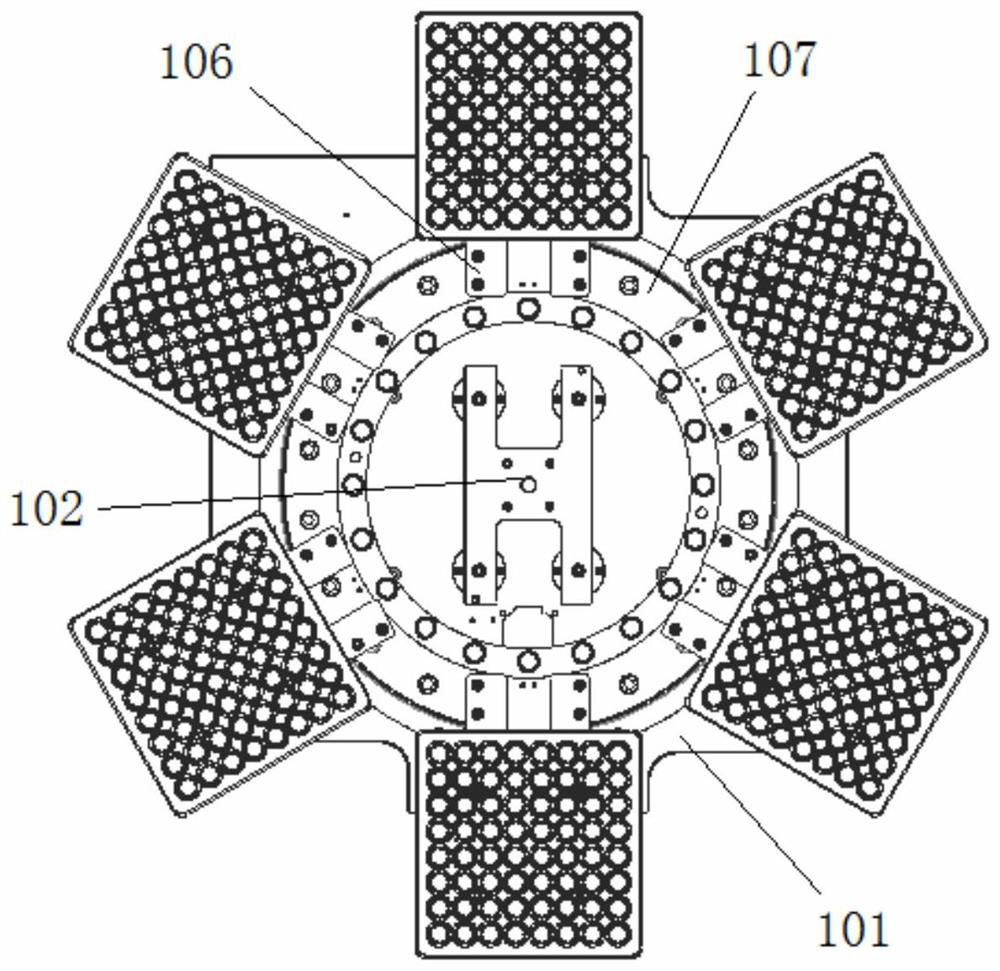

[0037] Such as Figure 1-16 As shown, the present invention includes a robot mechanism 10, an inner cylinder rotary feeding mechanism 1, an inner cylinder tray lifting mechanism 2 and a conveyor line support 12, the inner cylinder rotary feeding mechanism 1 is provided with a jacking mechanism, and the inner cylinder rotary feeding mechanism 1 The upper end is provided with a pallet turntable 107 with a plurality of tray support plates 106, and a through hole is provided in the middle of the tray turntable 107. When the mechanism is working, the potted flowers to be assembled are sent to the jacking mechanism through the potted flower conveying line, and Driven by the jacking mechanism, it is raised from the through hole in the middle of the tray turntable 107, and one side of the inner cylinder rotary feeding mechanism 1 is sequentially provided with an inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com