Automatic conveying flower basket buffer storage station based on AGV trolley

A technology of automatic transmission and cache station, applied in conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of reducing the productivity of photovoltaic cells, missing the best time, affecting photovoltaic production, etc., to reduce waiting time, improve Speed, the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

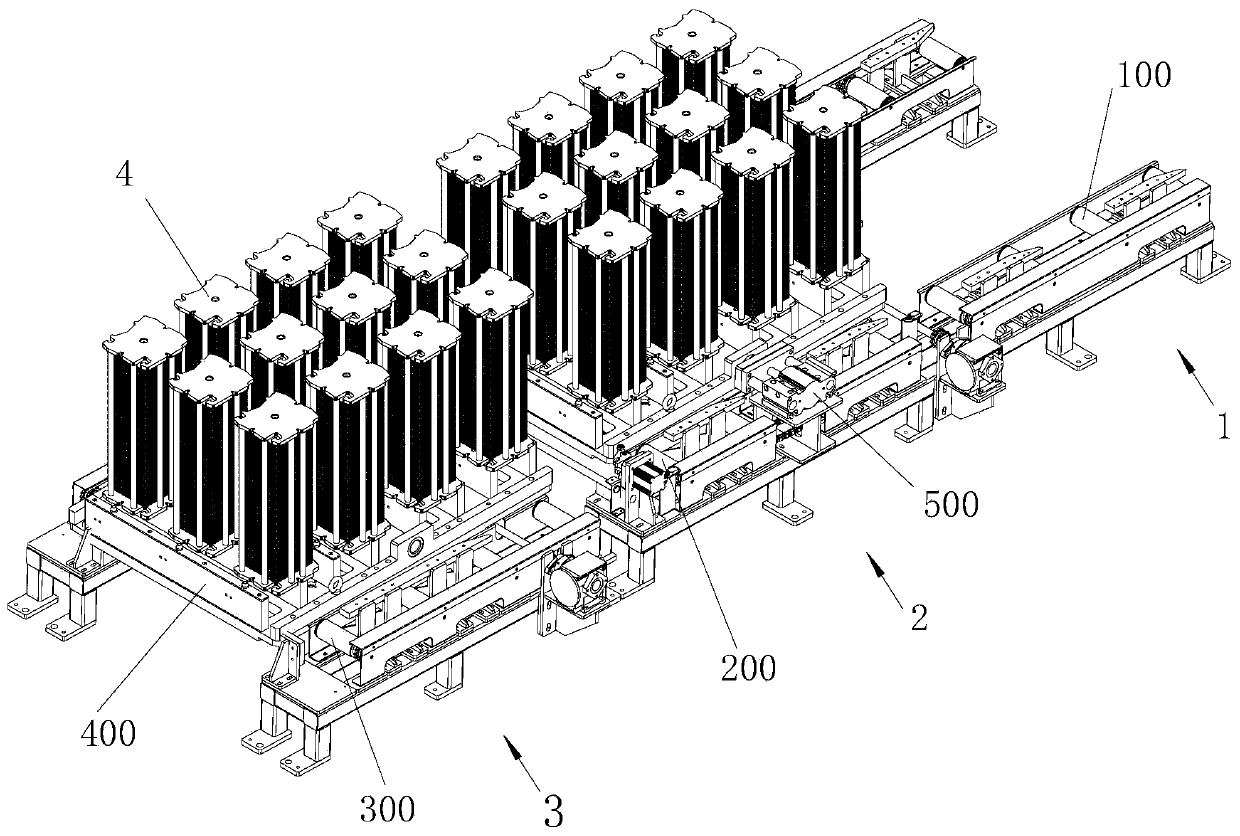

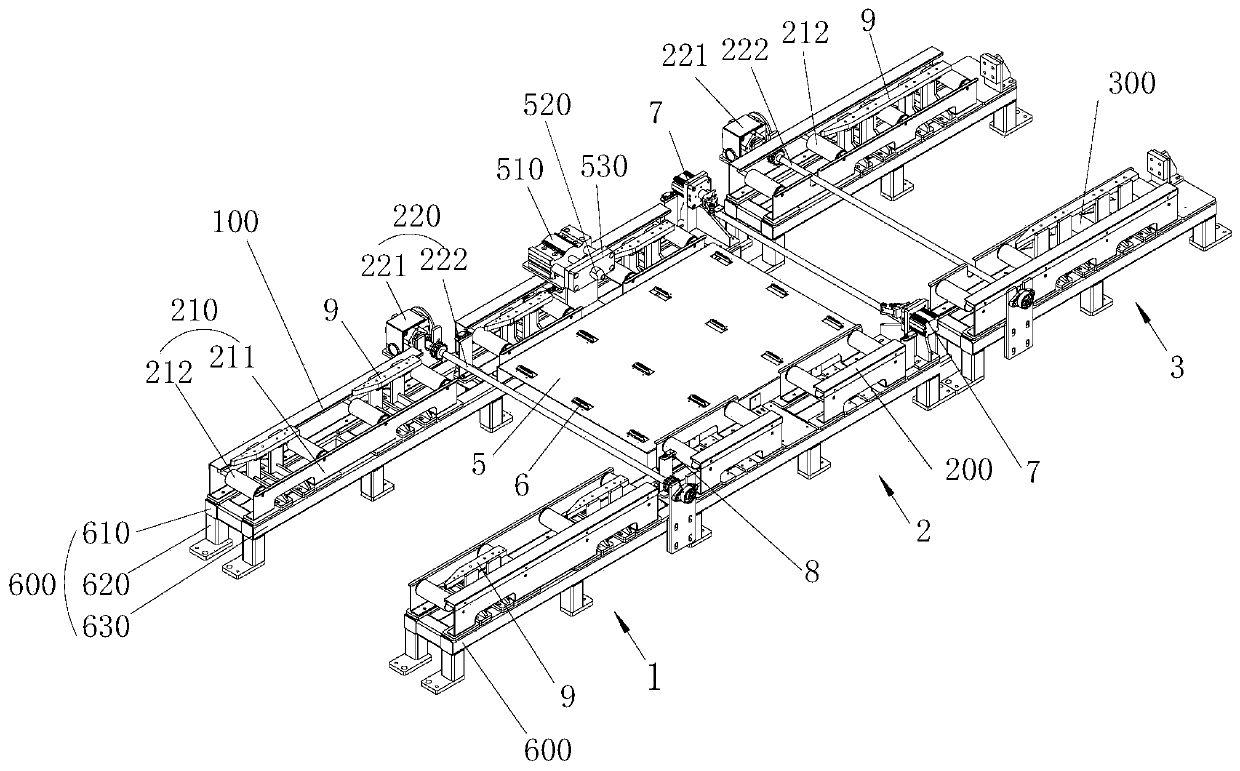

[0034] Such as Figure 1 to Figure 7 As shown, the flower basket cache station based on the automatic transmission of the AGV trolley in this embodiment includes a waiting position 1, a working position 2, and a buffering position 3 that are sequentially connected. 2 is provided with a working station transmission line 200 for transferring the tray 400, and the buffer station 3 is provided with a buffer station transmission line 300 for transferring the tray 400. The tray 400 is used to load the flower basket 4, and the working station 2 is provided with a tray positioning mechanism for positioning the tray 400 500, the input of the tray 400 on the waiting bit transmission line 100 and the output of the tray 400 on the cache bit transmission line 300 are transported by an AGV trolley (not shown in the figure). The working position 2 is mainly used for loading and unloading (inserting and removing pieces) of the flower basket 4, which is carried out by a manipulator (not shown ...

Embodiment 2

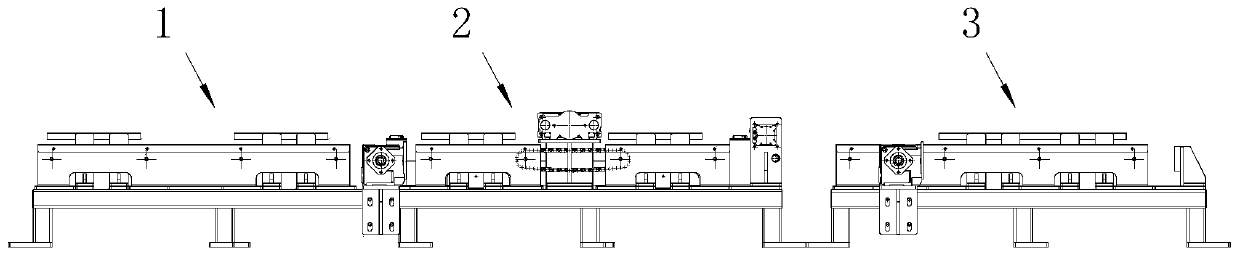

[0051] Such as Figure 8 to Figure 10 As shown, the flower basket cache station based on the automatic transmission of the AGV trolley in this embodiment differs from Embodiment 1 only in that:

[0052] In this embodiment, the waiting position 1, the working position 2 and the buffer position 3 have a certain height from the ground, and the transportation between the waiting position 1, the working position 2 and the buffer position 3 and the ground can be passed by the AGV trolley equipped with the flower basket 4. The channel 700, the waiting bit transmission line 100 and the buffer bit transmission line 300 are adjustable in height, so as to facilitate docking with the AGV trolley.

[0053] The height of the transportation channel 700 is greater than the total height of the AGV plus the flower basket 4, so that the AGV full of flower baskets can also pass through the buffer station. The base 600 of the waiting position 1 is a lifting base 640 , and the base 600 of the buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com