Cab turnover mechanical cylinder

A cab and mechanical technology, applied to the upper structure, the upper structure of the truck, transportation and packaging, etc., can solve the problems of leakage, inability to lift and flip the cab, and danger, so as to ensure safety and structure Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

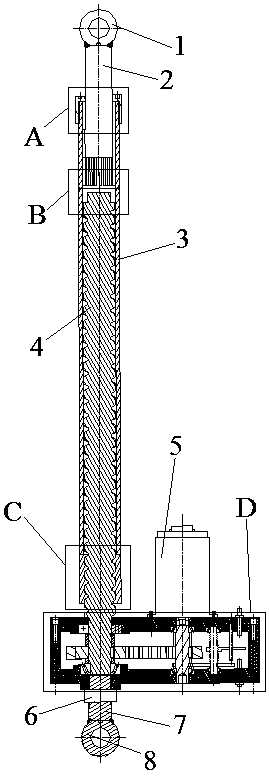

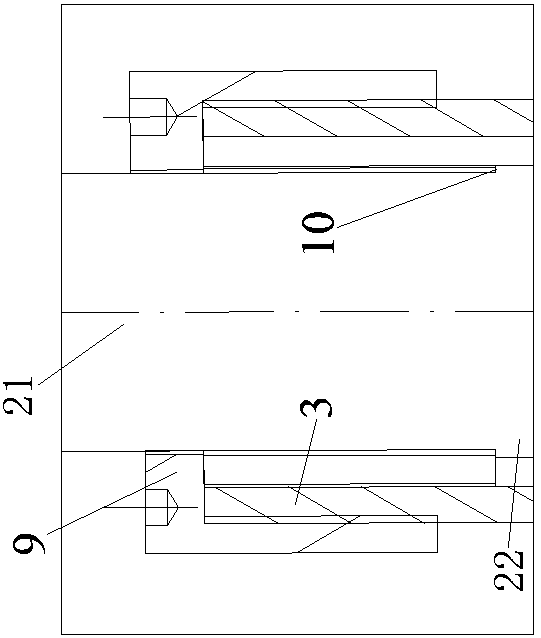

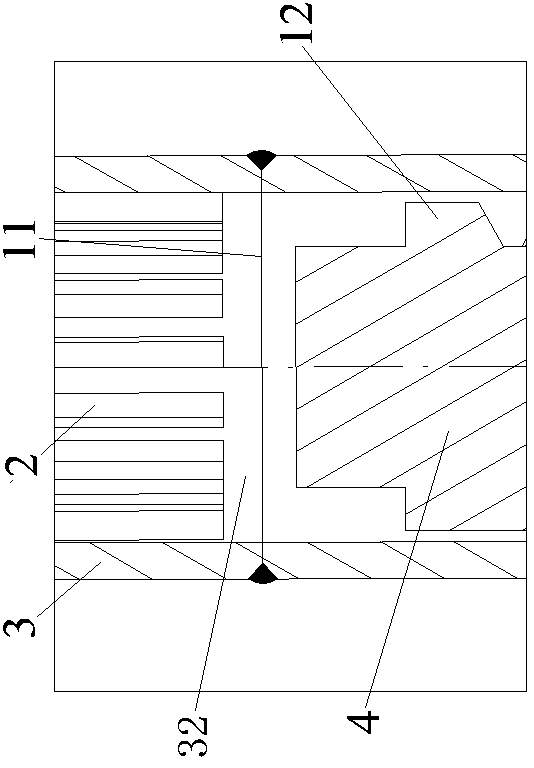

[0013] One end of the rod 2 of the present invention is fixedly installed with a cab end shaft sleeve 1, and the cab end shaft sleeve 1 is in the form of a shaft sleeve. The shaft sleeve is sleeved on the horizontal axis of the bottom end of the cab and can rotate on the horizontal axis. The other end of the rod 2 is inserted into the cylinder tube 3. The rod 2 is composed of an upper plunger 21 and a lower base 22. The outer diameter of the lower base 22 is larger than the outer diameter of the upper plunger 21, forming a clamping table 10, which is installed at the top of the cylinder 3. There is an end cover 9, which is sleeved outside the upper inserting rod 21; through this structure of the rod 2, the limit of the clamping table 10 and the end cover 9 can be matched to limit the stroke of the rod 2, that is, the rod 2 It can move up and down in the cylinder 3, but is restricted by the positioning table 10. The inside of the cylinder 3 is divided into a rod buffer cavity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com