A leather connecting line cutting device

A technology of cutting device and connecting line, applied in raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur processing, small raw hide/large raw hide/leather/fur mechanical processing, etc., can solve the problem of low work efficiency , hand cut, time-consuming and other problems, to achieve the effect of protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

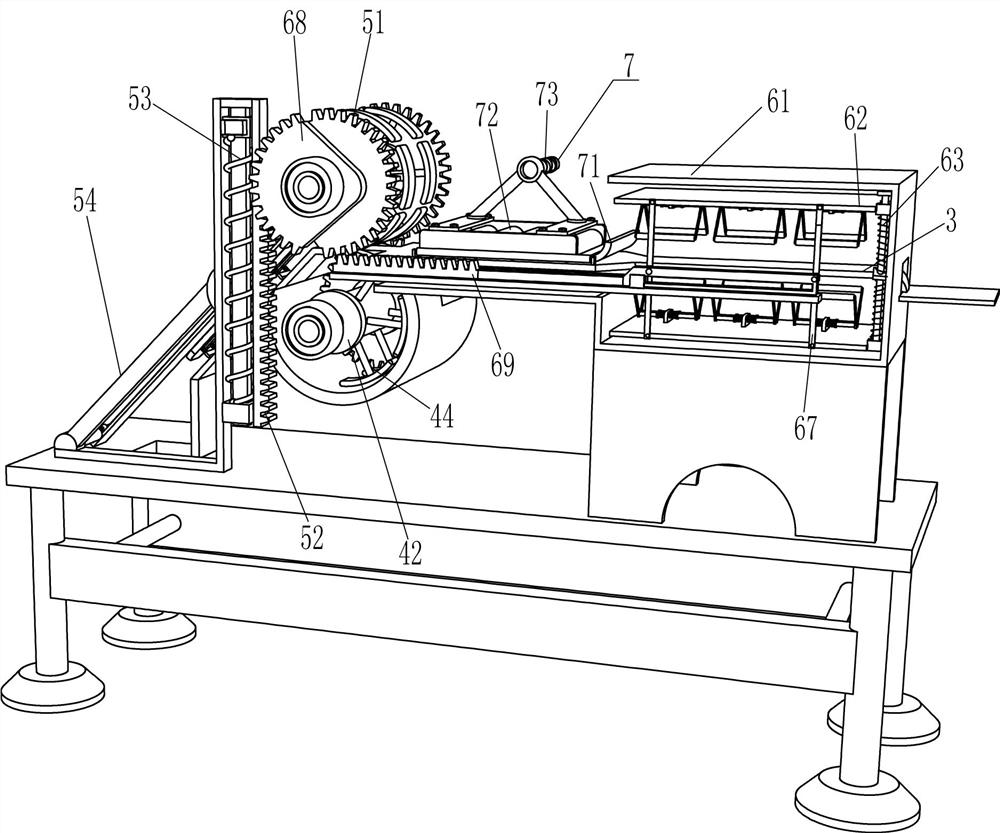

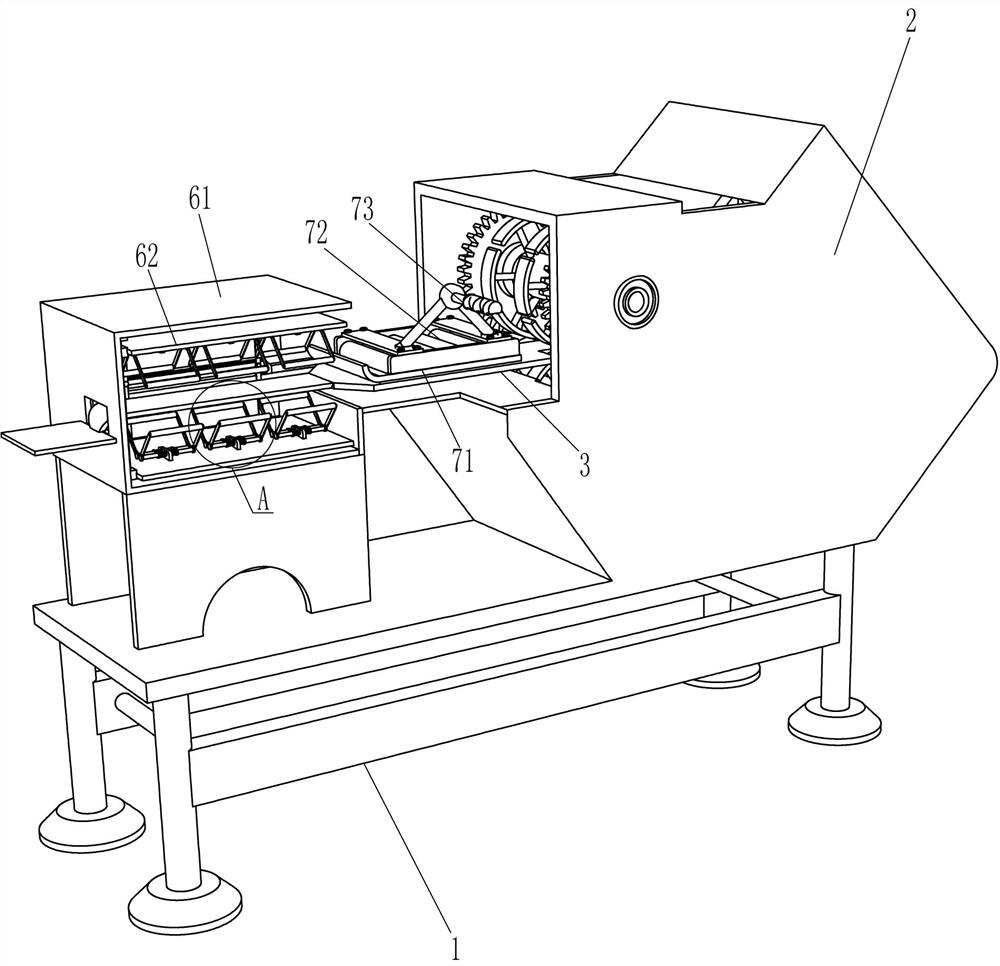

[0022] A leather connecting wire cutting device, such as Figure 1-5 As shown, it includes a bracket 1, a chassis 2 and a placement board 3. The chassis 2 is installed on the top side of the bracket 1, and a placement board 3 is installed horizontally in the chassis 2. The placement board 3 is parallel to the bracket 1, and one end of the placement board 3 extends out of the chassis. 2. It also includes an intermittent pulling assembly 4 and a cutting assembly 5. The intermittent pulling assembly 4 and the cutting assembly 5 are arranged in the chassis 2. The intermittent pulling assembly 4 and the cutting assembly 5 are connected by transmission. The mouth is located below the cutting assembly 5 .

[0023] When the leather is sealed and the edge needs to be cut off to separate the leather, the collection frame is first placed on the bottom of the discharge port, and then the leather is placed on the placement plate 3. At this time, the intermittent pulling assembly 4 is start...

Embodiment 2

[0029] On the basis of Example 1, such as figure 1 , figure 2 , image 3 and Figure 6As shown, it also includes a leveling assembly 6, and the leveling assembly 6 includes a mounting frame 61, a slide plate 62, a return spring 63, a torsion spring 64, a first connecting rod 65, a roller 66, a second connecting rod 67, a second The sector gear 68 and the second rack 69 are connected to the mounting frame 61 on the other side of the top of the bracket 1, and two sliding plates 62 are slidably connected in the mounting frame 61. The two sliding plates 62 are all parallel to the bracket 1, and the two sliding plates The plates 62 are set up and down, and a return spring 63 is connected between the sliding plate 62 and the middle part of the installation frame 61. Three swing seats are evenly spaced on the opposite side of the two slide plates 62, and each swing seat is rotating. Two rotating shafts are connected, and the first connecting rod 65 is hingedly connected to both e...

Embodiment 3

[0032] On the basis of Example 2, such as Figure 1-2 As shown, it also includes an ironing assembly 7. The ironing assembly 7 includes a connecting plate 71, a heating roller 72 and a handle 73. A heating roller 72, a handle 73 is connected to the connecting plate 71, and the handle 73 is connected to the connecting plate 71 by welding.

[0033] After the leather is flattened, the leather is located in the middle of the placement plate 3, and the handle 73 can be pulled to drive the heating roller 72 to move downward through the connecting plate 71. After the heating roller 72 contacts the leather, the leather is heated, and the leather is heated. It can also flatten the leather during the process, so as to shape the leather again and prevent the leather from bending again after cutting.

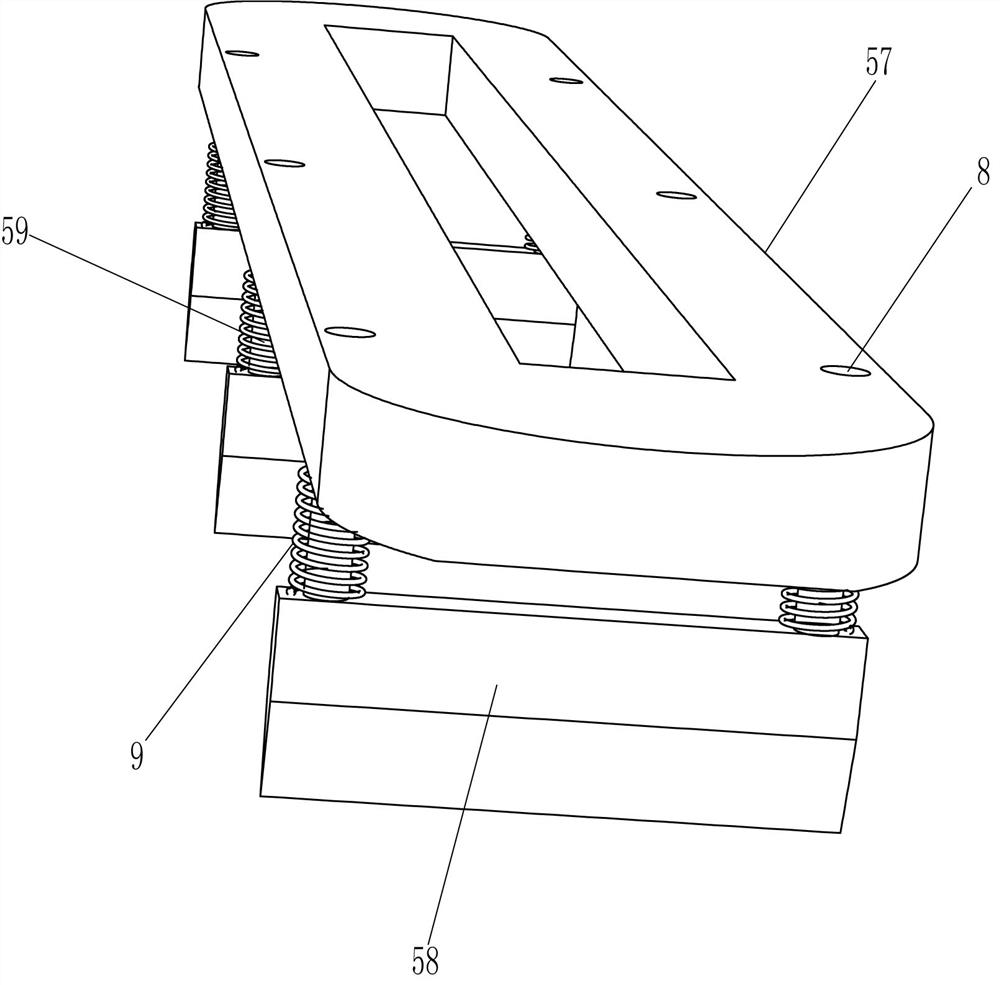

[0034] Such as Figure 5 Shown, also comprise elastic member 9, have through hole 8 on the mounting plate 57, connecting rod 59 and through hole 8 sliding fit, be connected with elastic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com