Efficient metal plate stamping equipment

A stamping equipment and sheet metal technology, which is applied in the field of high-efficiency sheet metal stamping equipment, can solve the problems of low production efficiency, unstable product quality, and high processing costs of stamping equipment, so as to improve production efficiency, reduce labor intensity, production costs, and quality The effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

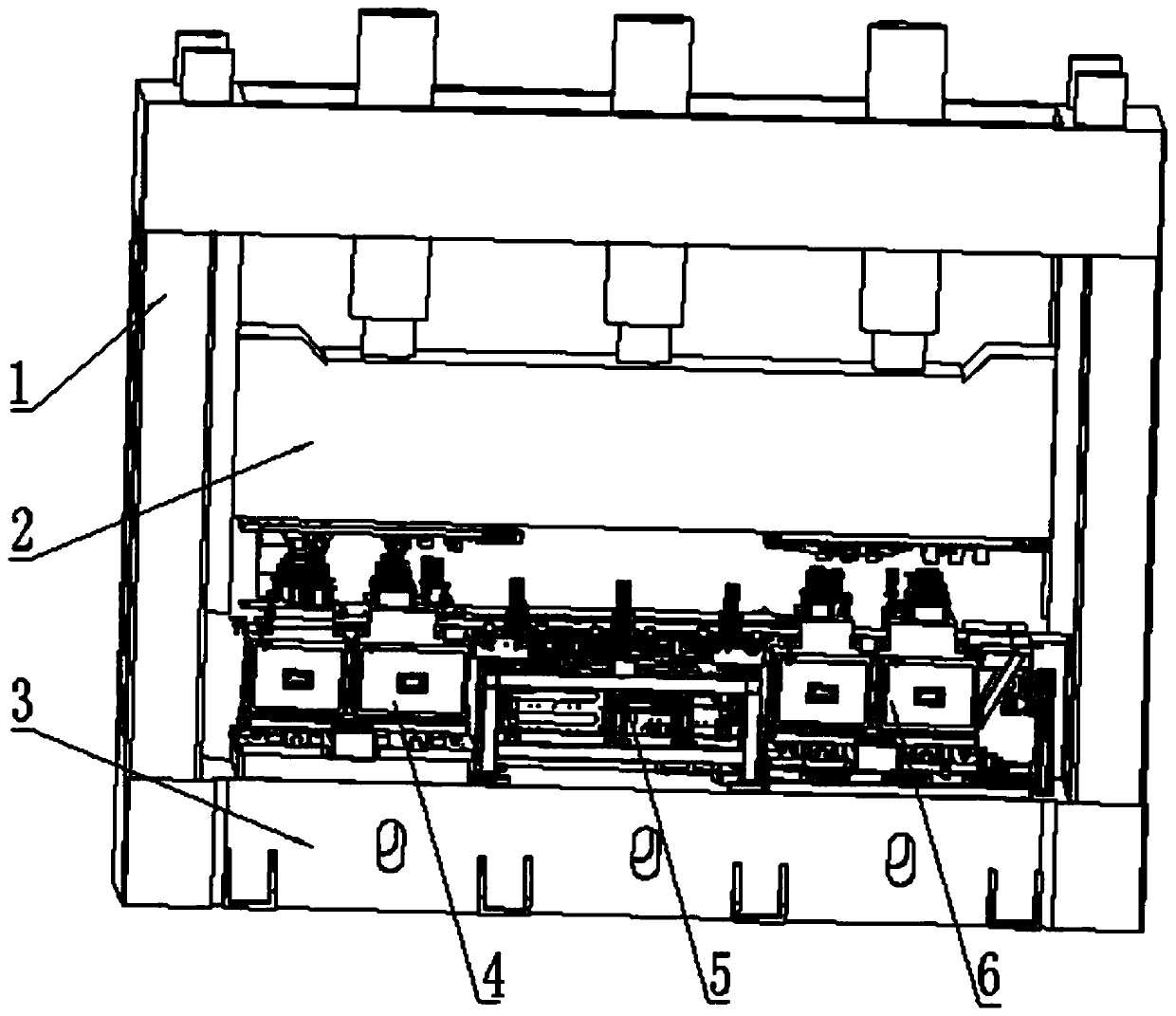

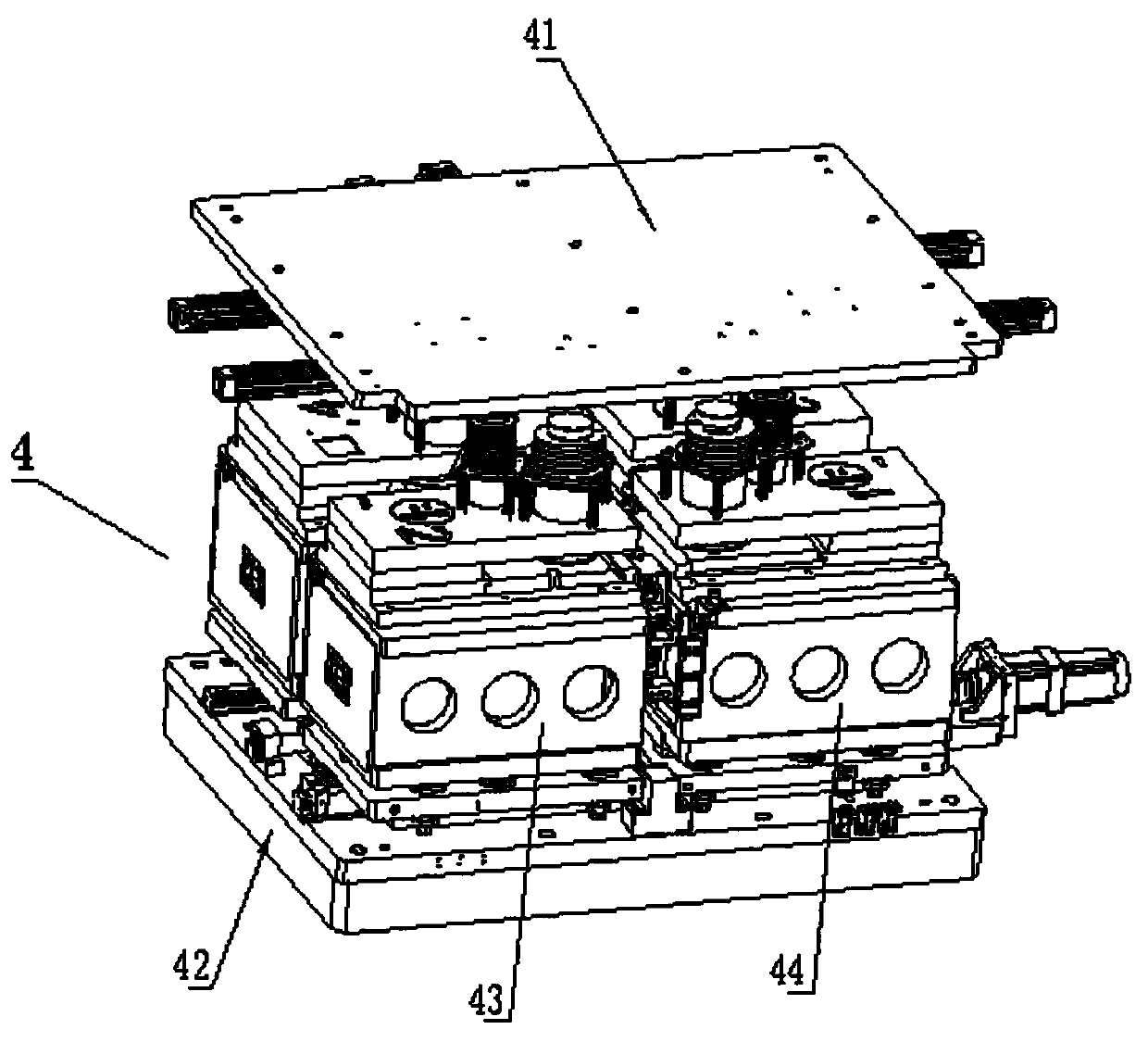

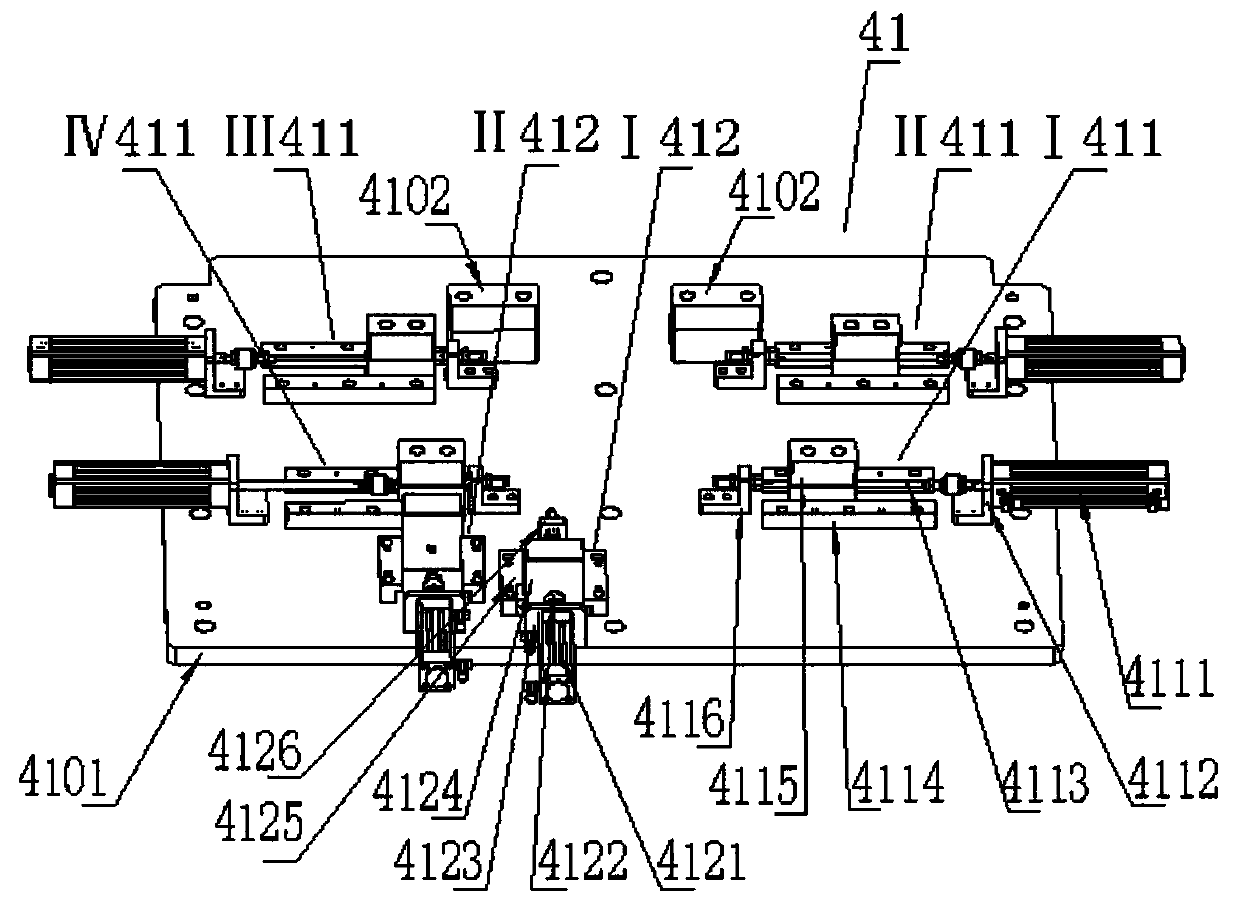

[0039] Such as Figure 1 to Figure 18As shown, a high-efficiency sheet metal stamping equipment includes: press body 1, press slider 2, press table 3, front stamping assembly 4, conveying assembly 5, rear stamping assembly 6, front press head assembly 41 , the front stamping die drive assembly 42, the front left stamping die assembly 43, the front right stamping die assembly 44, the lifting gear assembly 443, the large fixed plate 4101, the fixed pressure block 4102, the cylinder 4111, the support 4112 , connecting rod 4113, guide block 4114, mobile pressure, 4115, buffer positioning mechanism 4116, support 4121, cylinder 4122, connecting rod 4123, moving pressure block 4124, guide block 4125, support 4126, large backing plate 4201, large Fixed plate 4202, front bearing block 4203, linear slide rail pair 4204, support 4205, servo drive 4206, right-handed nut block 4207, bidirectional ball screw 4208, centering calibration block 4209, left-handed nut block 4210, mold bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com