Novel self-cleaning type engine connecting rod vibration deslagging device

An engine connecting rod and self-cleaning technology, applied in cleaning methods and appliances, cleaning methods using gas flow, chemical instruments and methods, etc., can solve the problems of reduced work efficiency, poor slag removal effect, increased labor load, etc. problems, to achieve the effect of improving cleanliness, avoiding structural jamming, and reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0028] The vibration motor 408 (model JZO-50-4) mentioned in the present invention can be purchased from the market or obtained by private customization.

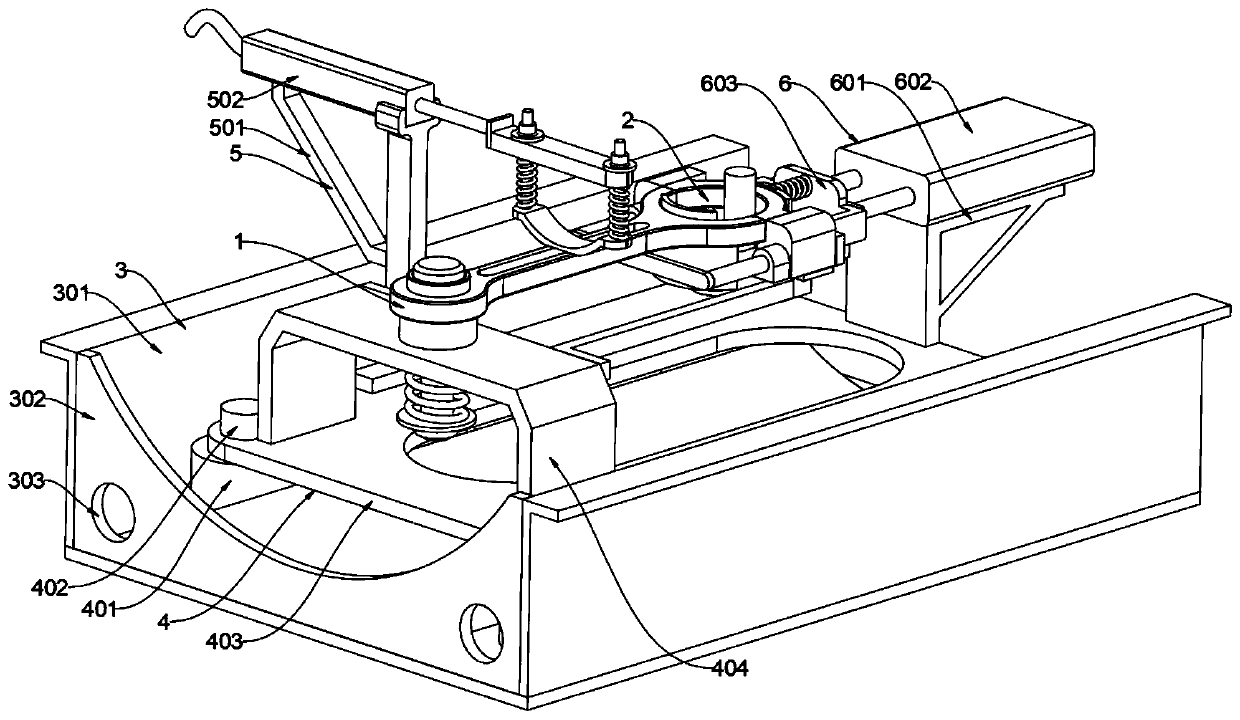

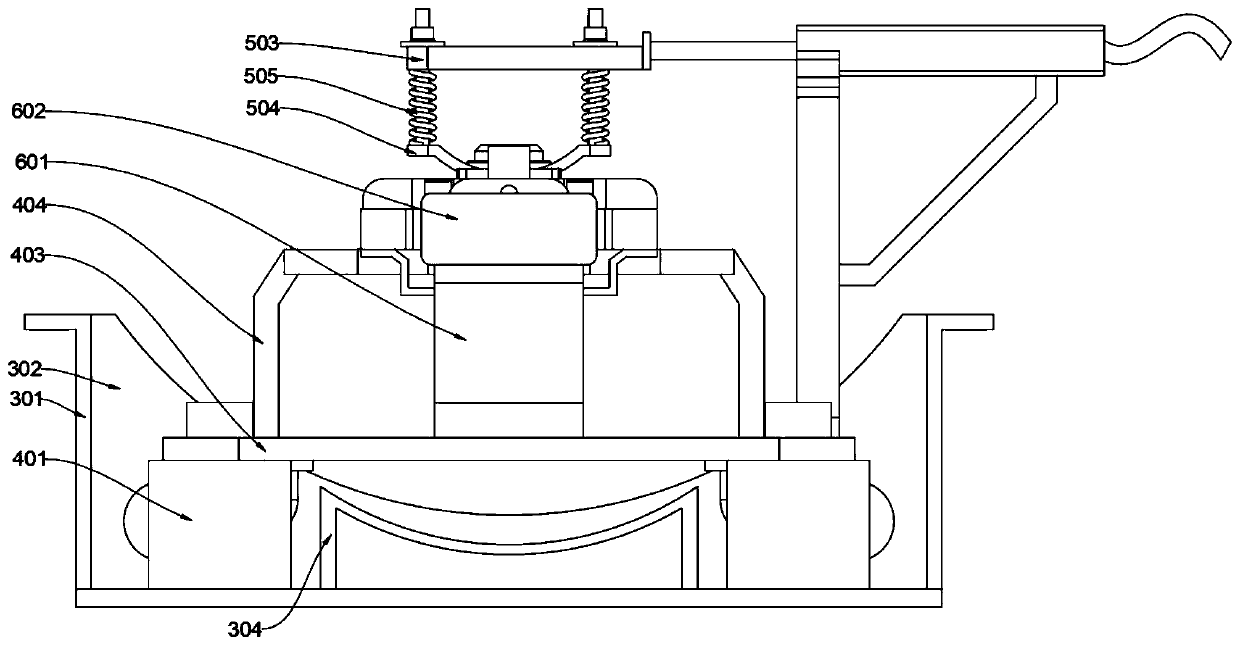

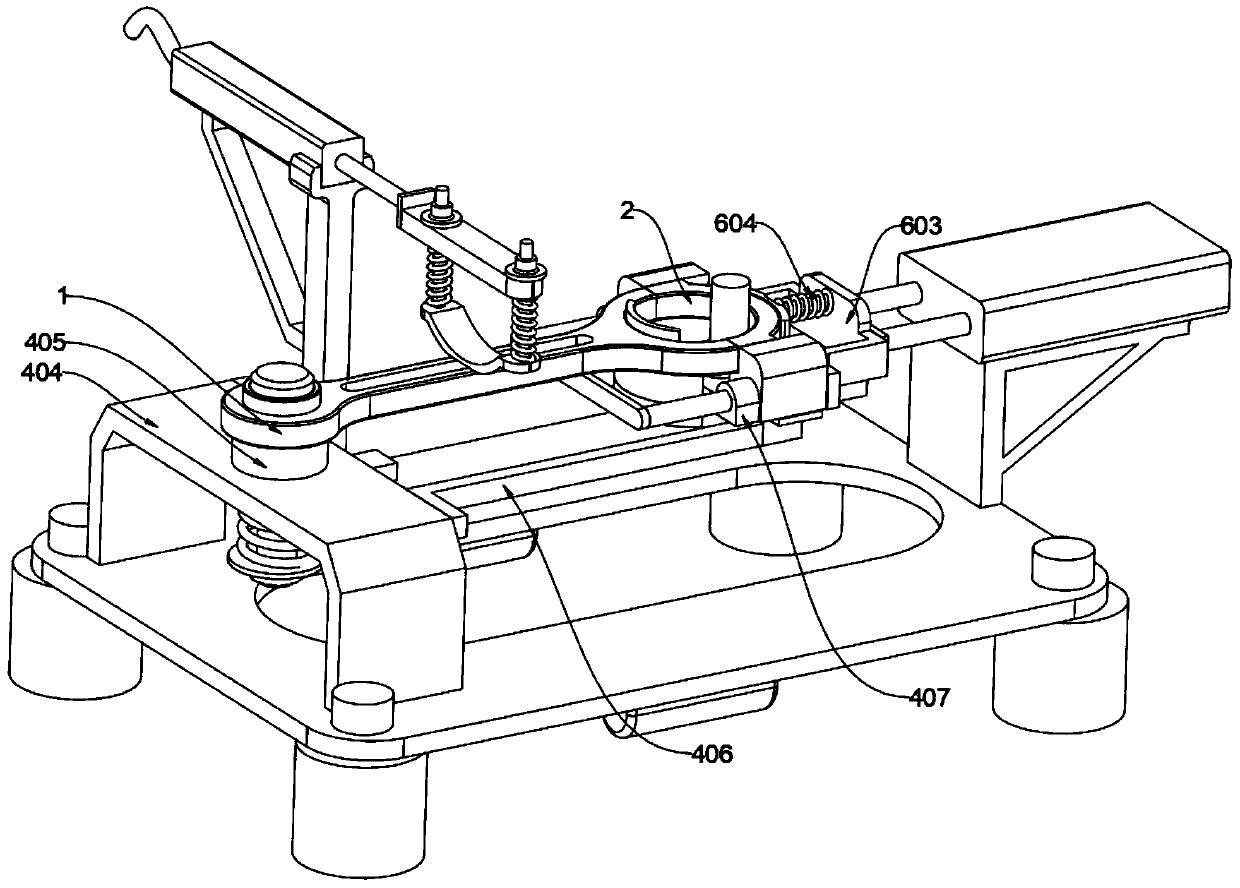

[0029] see Figure 1 to Figure 7 , an embodiment provided by the present invention: a new self-cleaning engine connecting rod vibration slag removal device, including a connecting rod main body 1, a rod pressing mechanism 5 is installed on the upper end surface of the connecting rod main body 1, and the rod pressing mechanism 5 is The tightening mechanism 5 can compress the connecting rod main body 1 to avoid the deviation of the connecting rod main body 1 when it vibrates. The slag collecting mechanism 3 is supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com