Shaft sleeve detection sorting device and method

A sorting device and bushing technology, applied in sorting and other directions, can solve the problems of easy false detection, low detection efficiency of bushings, missed detection, etc., and achieve the effect of high detection accuracy and improved detection and sorting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

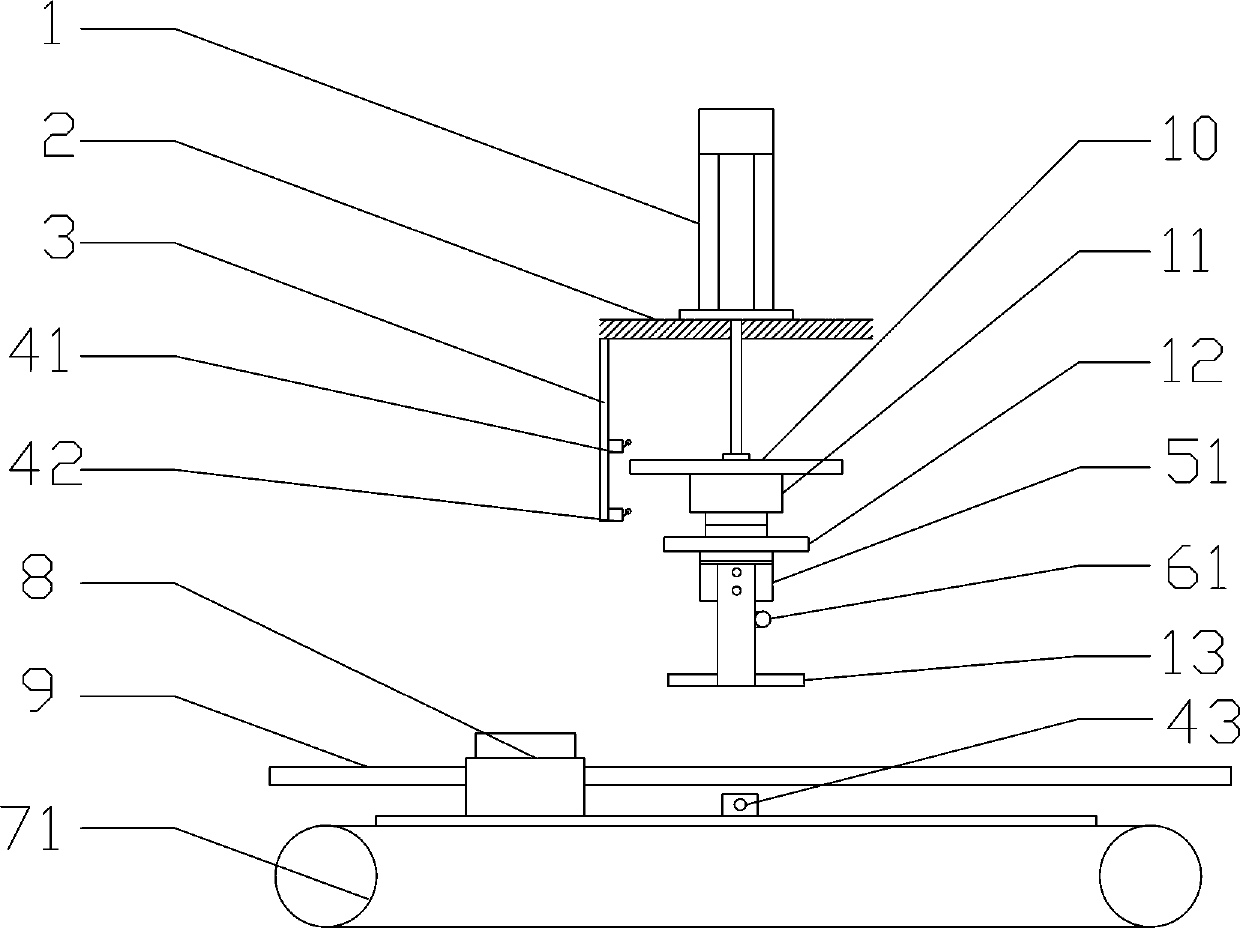

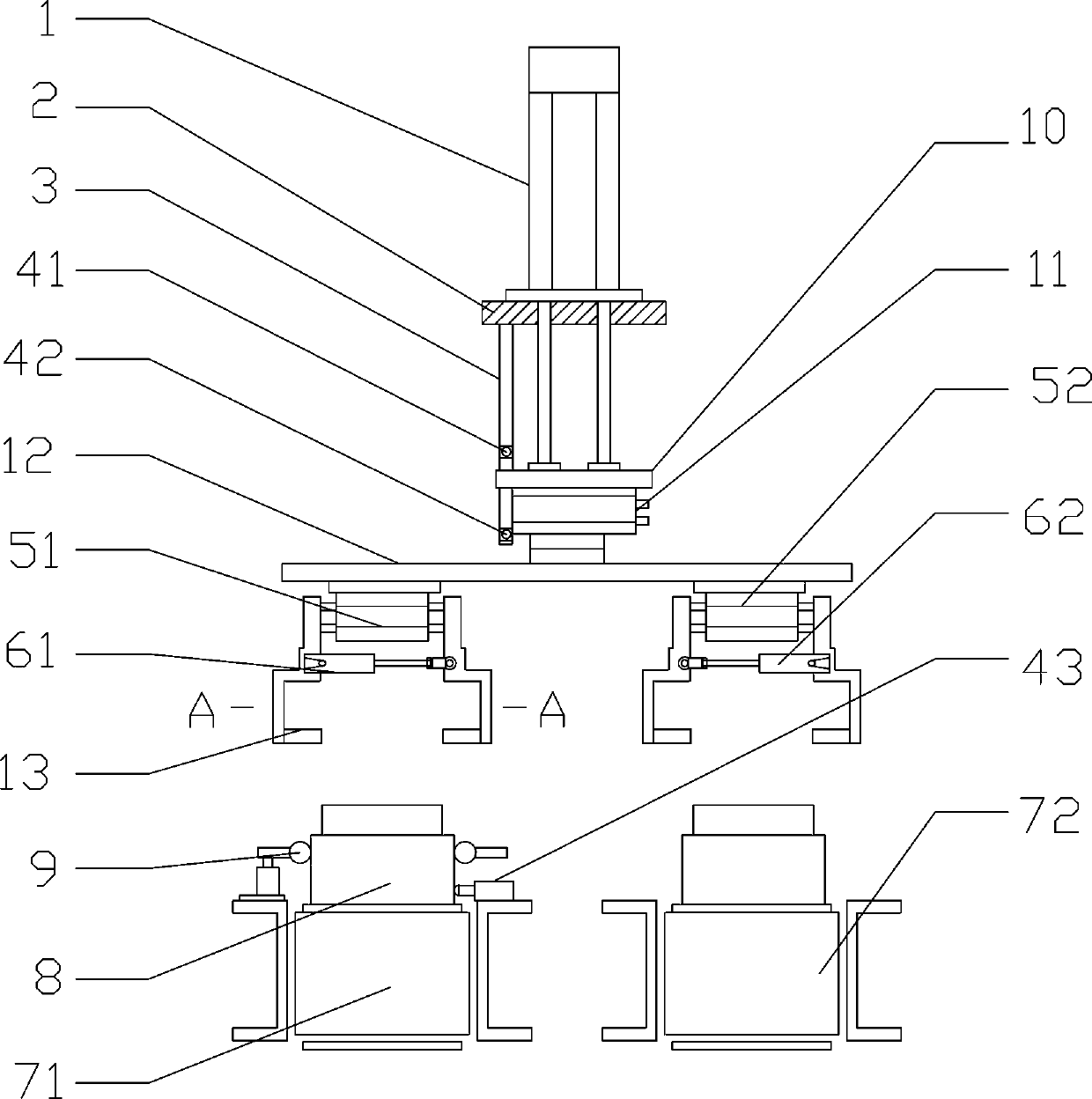

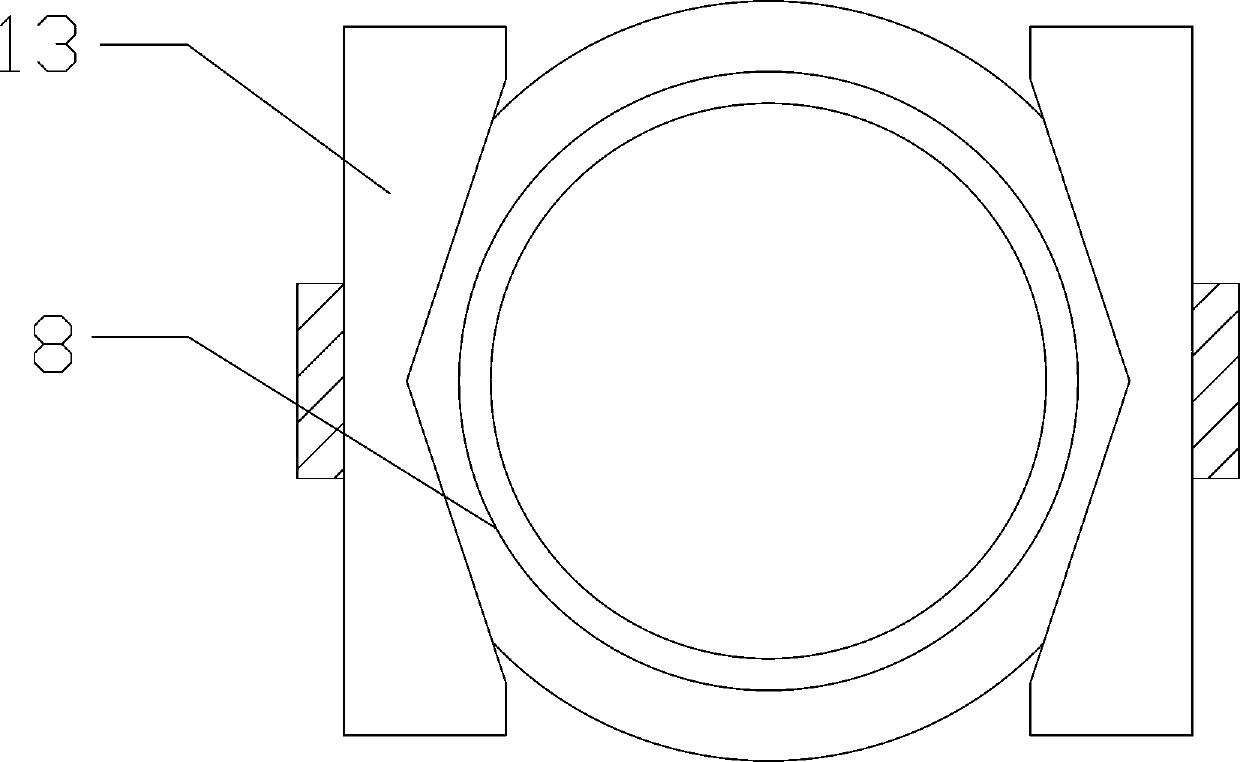

[0015] Such as Figures 1 to 5 As shown, a shaft sleeve detection and sorting device includes a first belt conveyor 71, and the frame of the first belt conveyor 71 is provided with two guide rods 9, and the two guide rods 9 are mounted on the first belt conveyor 71. A channel is separated, and the first belt conveyor 71 carries the bushing 8 through the passage. During the conveying process of the bushing 8 on the first belt conveyor 71, two guide rods 9 are attached to both sides of the bushing 8. A support 2 is provided on one side of the first belt conveyor 71, and a biaxial linear cylinder 1 is installed on the support 2. The lower end of the piston rod of the linear cylinder 1 is connected to the rotary cylinder 11 through the first support plate 10, and the second support plate 12 is connected to the On the rotary end of the rotary cylinder 11, a first pneumatic gripper 51 is installed at one end of the second support plate 12, and splints 13 are respectively fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com